Eccentric oscillating gear unit

A technology of gear device and eccentric swing, applied in the direction of gear transmission device, transmission device, transmission device parts, etc., can solve the problem of difficult to fully ensure the bearing support capacity for supporting the crankshaft, and achieve the effect of increasing the support capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, an example of embodiment of the present invention will be described in detail based on the drawings.

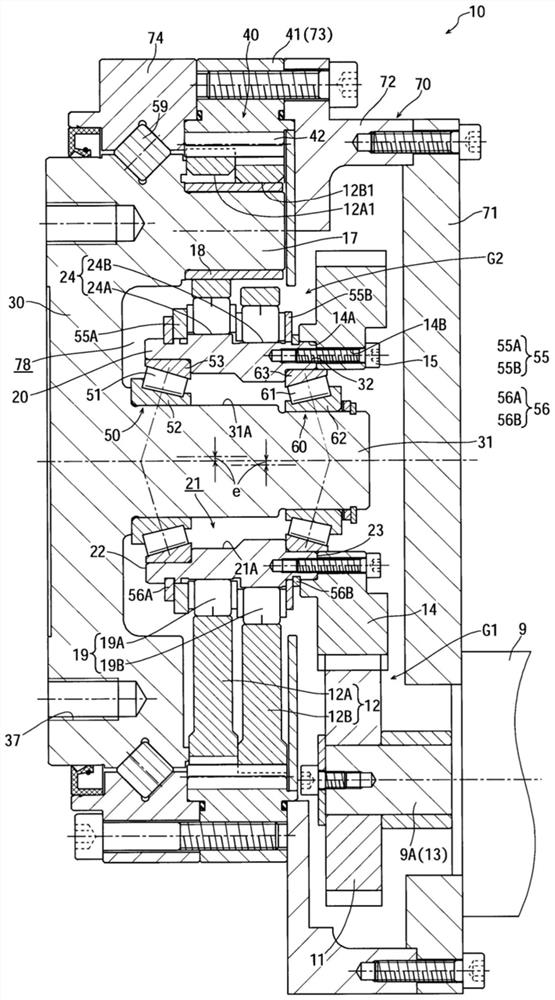

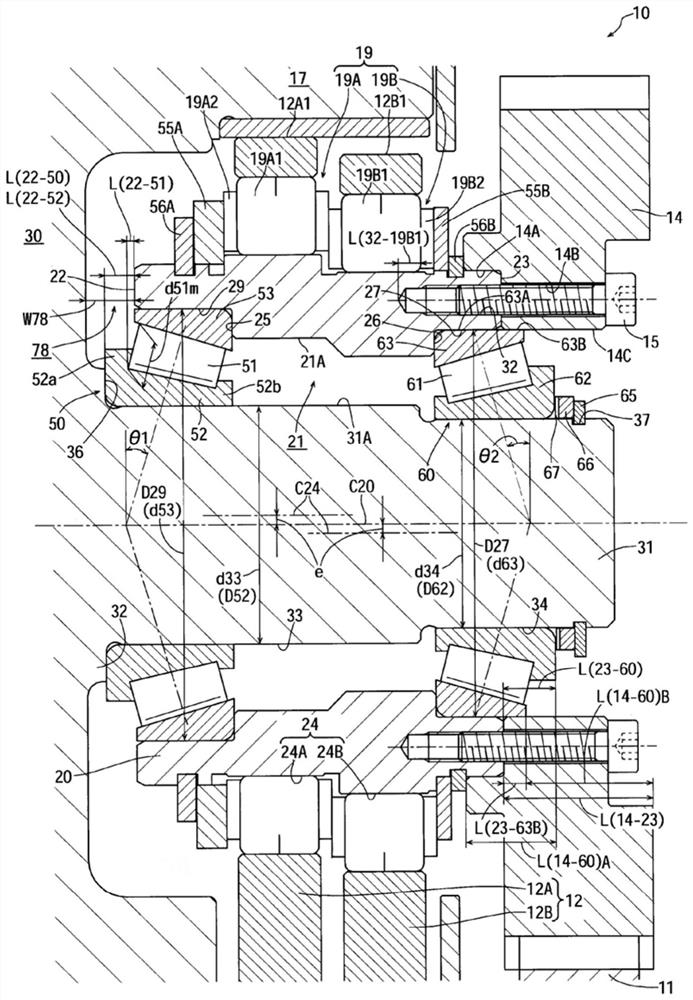

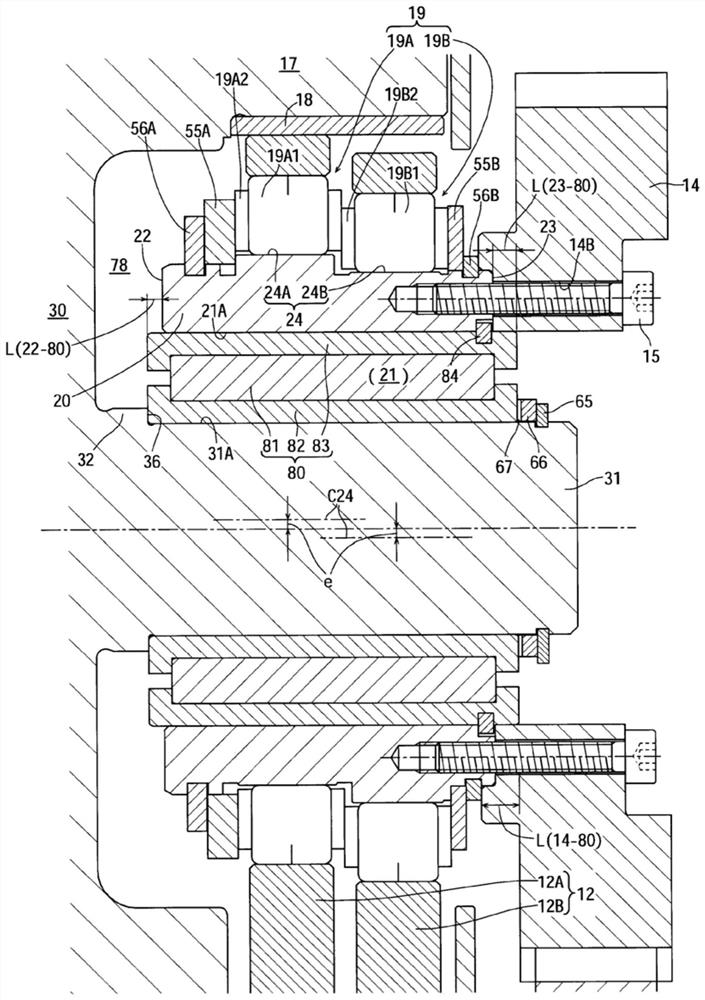

[0019] figure 1 It is a sectional view showing the structure of an eccentric oscillating gear device according to an example of an embodiment of the present invention, figure 2 yes figure 1 An enlarged view of the main part.

[0020] Roughly speaking, the gear unit 10 includes two external gears (oscillating gears) 12 ( 12A, 12B) and a crankshaft 20 for oscillating and rotating the external gears 12 . The gear unit 10 includes a carrier (flange member) 30 arranged to face the crankshaft 20 in the axial direction, and the external gear 12 and the internal gear 40 (not Swing gear) between the relative rotation.

[0021] The crankshaft 20 has a hollow portion 21 , and the wheel carrier 30 has a shaft member 31 inserted into the hollow portion 21 . In addition, inner bearings (the first inner bearing 50 and the second inner bearing 60 ) are disposed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com