Colloidal-silica-coated magnesium hydroxide

A magnesium hydroxide, coating technology, applied in the direction of magnesium hydroxide, silicon oxide, silicon dioxide, etc., can solve the problem of damage to the appearance, and achieve the effect of high flexural modulus of elasticity and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

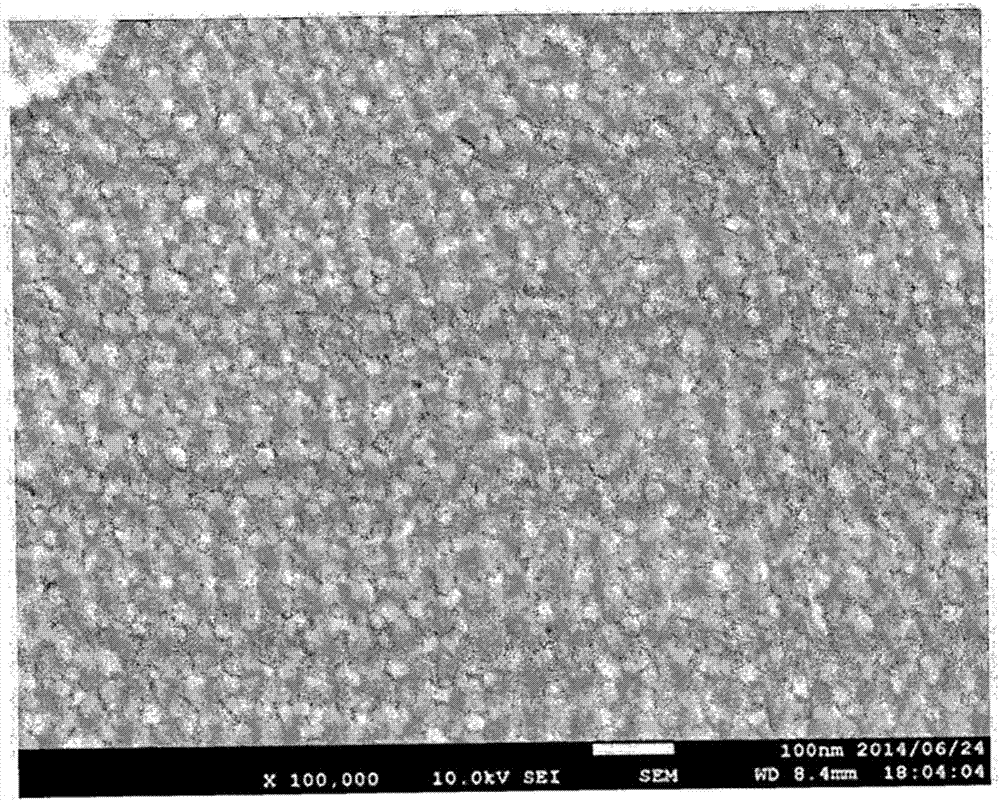

[0060] First, based on the method described in Patent Document 1 (International Publication No. 2011 / 073766), a mixed aqueous solution of magnesium chloride and sodium acetate (Mg=1.0 mol / L, sodium acetate=0.5 mol / L, 30° C. ), 3.4 L of 2 mol / L sodium hydroxide aqueous solution (30° C.) was added under stirring to carry out coprecipitation reaction. 1 L of the reactant was taken out, and hydrothermal treatment was performed at 160° C. for 5 hours in an autoclave. After cooling to below 100°C, it was taken out from the autoclave, filtered, washed with water, dried, and pulverized to obtain magnesium hydroxide powder sample 1. Table 1 shows the aspect ratio of the obtained powder.

[0061] Then, the powder sample 1 was emulsified in water to prepare a slurry so that the solid content concentration was 30g / L and the liquid volume was 1.55kL, and heated to 80°C while stirring, and silica gel (Cataloid SI-30 (NGC Catalytic Chemicals Co., Ltd., average particle size 12nm, SiO 2 Co...

Embodiment 2

[0063] Powder sample 3 was obtained in the same manner as in Example 1, except that the addition was converted to SiO 2 4.0% by weight of silica gel with respect to 100% by weight of magnesium hydroxide. Table 1 shows the aspect ratio of the obtained powder.

Embodiment 3

[0064] Embodiment 3 (preparation of resin composition)

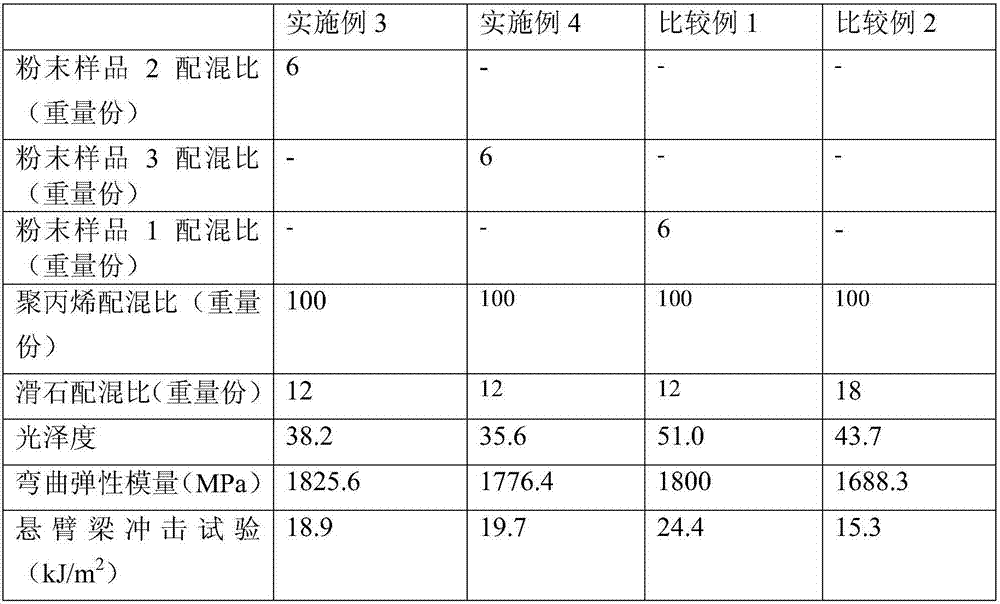

[0065] 6 parts by weight of the powder sample 2 prepared in Example 1, 100 parts by weight of polypropylene, and 12 parts by weight of talc were mixed and melt-kneaded at about 180° C. using a twin-screw extruder to form pellets. Using the obtained pellets, a test piece was formed by an injection molding machine at about 200° C., and its physical properties were measured. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com