Jacket hot melting tool of water filtering element

A technology of hot-melt and coat, which is applied in the field of hot-melt tooling for the jacket of the filter water core, which can solve the problems of not being easy to deform, and achieve the effects of reasonable structural configuration, convenient use, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

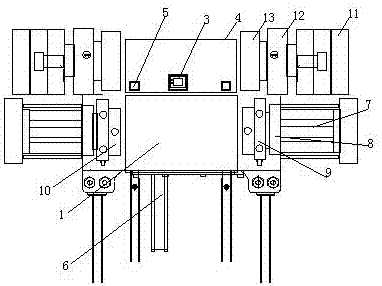

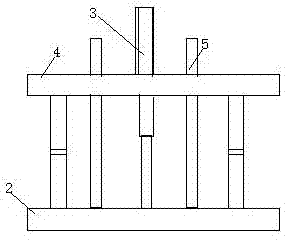

[0018] Example 1, as figure 1 , 2 As shown in Fig. 3, a hot-melt tooling for the outer jacket of a filter water core includes a main body clamping structure and a group of hot-melt welding structures arranged on both sides of the main body clamping structure. The lower part of the main body clamping structure is arranged in a movable On the assembly, the moving assembly includes a base 1, a workpiece clamping base 2 arranged on the upper part of the base 1, and an output end of a vertical telescopic cylinder 3 is arranged on the upper part of the workpiece clamping base 2. The fixed body of the telescopic cylinder 3 is connected with the pressing clamping member 4 , a set of guide columns 5 are also arranged on the upper part of the workpiece clamping base 2 , and the lower part of the base 1 is also connected with a translation cylinder 6 .

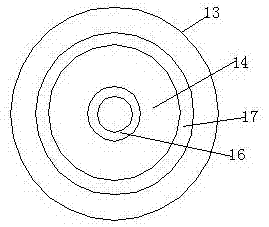

[0019] It is characterized in that: the hot-melt welding structure includes a hot-melt flaring unit and an end cover hot-melt unit, th...

Embodiment 2

[0022] Example 2, as Figure 4 As shown, on the basis of Example 1, in order to be suitable for the hot-melting of an end cap implementing a hot-melting structure, the end-cap hot-melting unit is arranged on the right side of the main body clamping structure as the structure of claim 2, Another cover hot-melt unit structure is provided on the left side of the main body clamping structure.

[0023] The other type of cover hot-melt unit structure includes a moving heat-conducting seat 18, a connecting seat disposed at the front end of the moving heat-conducting seat 18, and a hot-melting support block 19 disposed at the front end of the connecting seat. The hot-melt tank 20 is provided with a port hot-melt ring 21 at the center of the hot-melt tank 20 , and a central hot-melt abutment block 15 is provided on the hot-melt groove inside the port hot-melt ring 21 .

[0024] The tooling structure is reasonably configured and easy to use, which ensures that the outer end of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com