Fiber interface module

An optical fiber interface component and optical fiber technology, applied in the field of optical fiber interface components, can solve the problems of low coupling power that cannot meet the requirements of communication, deviation of the consistency of laser output angle, complex manufacturing process, etc., to achieve high return loss and improve product performance , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

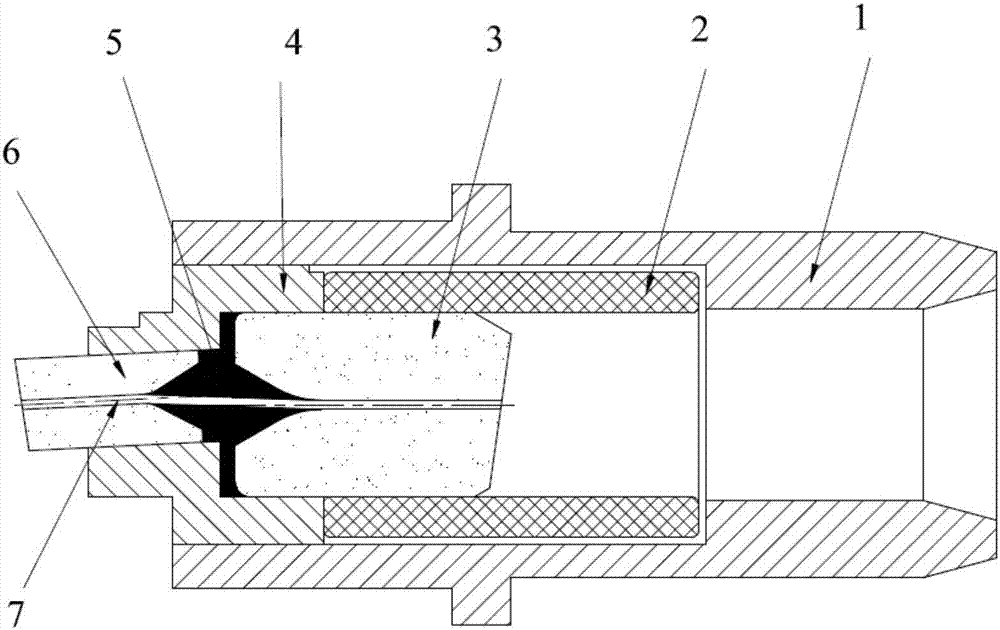

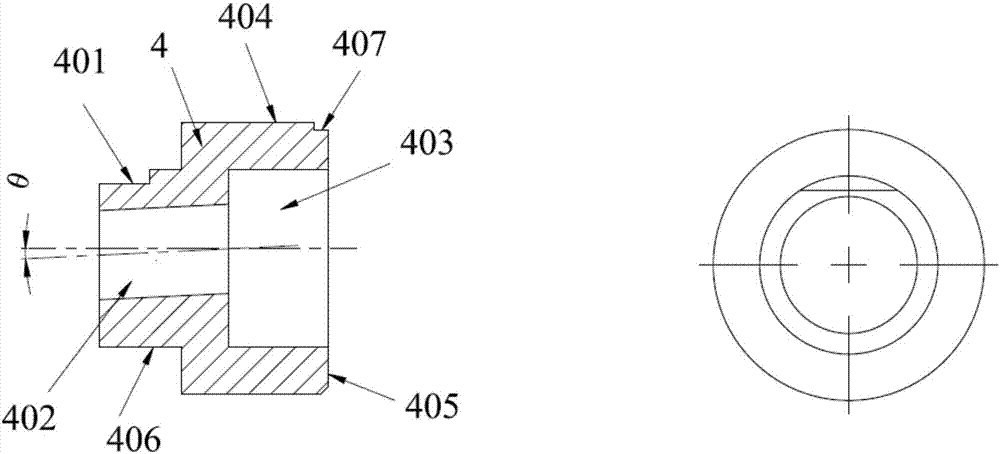

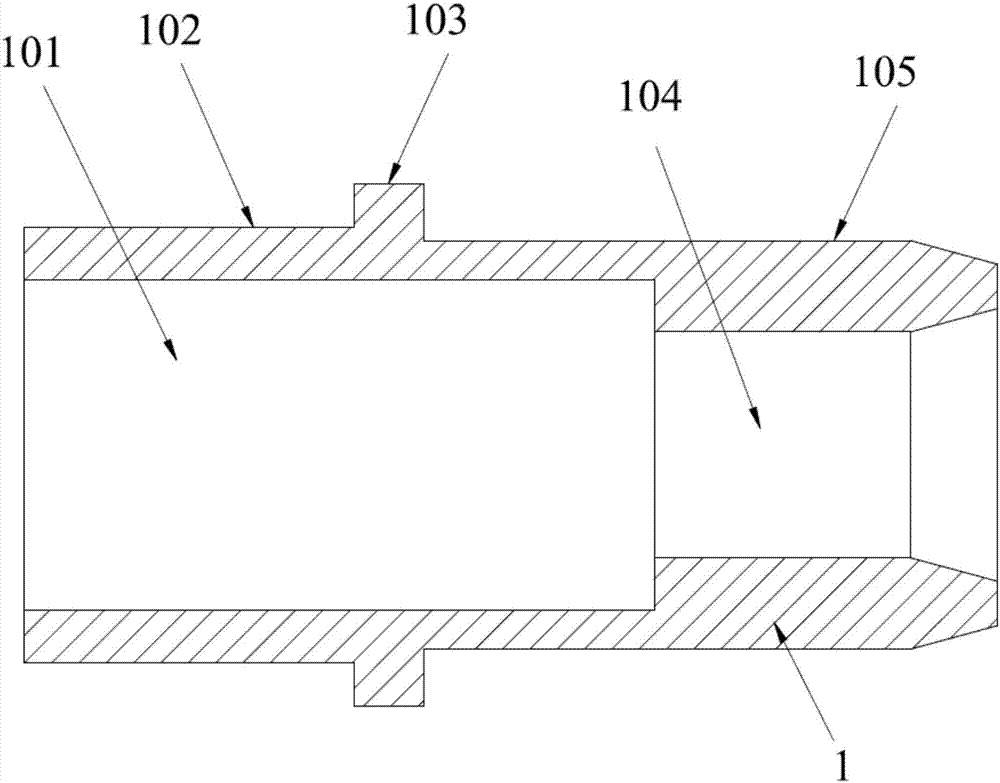

[0020] Such as figure 1 As shown, the optical fiber interface assembly includes a metal tail plug 1, a ceramic sleeve 2, a second ceramic ferrule 3, a metal base 4, a first ceramic ferrule 6 and an optical fiber 7, and the ceramic sleeve 2 is arranged on the In the middle of the metal tail plug 1, the metal base 4 includes a first cavity 402 and a second cavity 403, the first cavity 402 is arranged on the top of the second cavity 403 and communicated with each other, and the first cavity 402 is connected to the top of the second cavity 403. There is an included angle between the central axis of a cavity 402 and the central axis of the second cavity 403, the metal base 4 is arranged on the top of the metal tail plug 1, and the second ceramic ferrule 3 The tail end is inserted into the ceramic sleeve 2, the top end is inserted into the second cavity 403, the first ceramic ferrule 6 is inserted into the first cavity 402, and the optical fiber 7 is set in the first cavity 403. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com