Rear fire grate segment tensioning device of garbage incinerator and garbage incinerator

A technology of waste incinerator and tensioning device, which is applied to incinerators, combustion types, combustion methods, etc., can solve the problems of economic loss, difficulty in taking out the incinerator, and the rear grate pieces falling into the slag well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

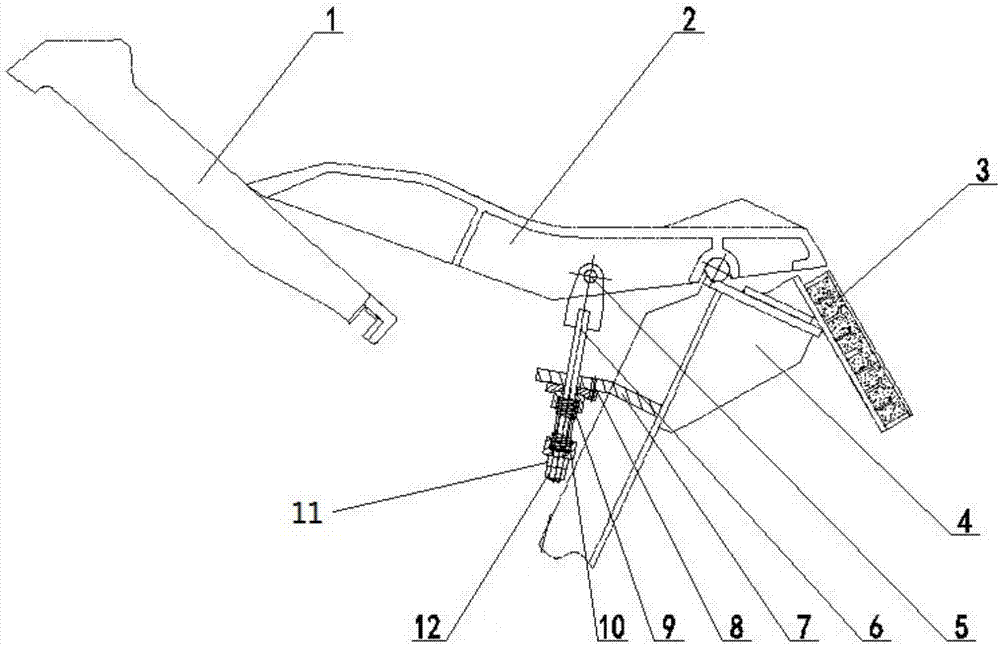

[0016] Such as figure 1 As shown, a rear grate tensioning device of a garbage incinerator includes a pull rod 6, a moving grate 1, a rear grate 2 and a grate support 4, and the grate support 4 is provided with a rear grate attachment 3. The end of the grate bracket 4 is provided with a fixed block 7, and the pull rod 6 passes through the fixed block 7 to connect with the rear grate piece 2, and the rear grate piece 2 presses the moving grate piece 1, and the pull rod 6 is provided with a compression adjustment mechanism that pulls the rear grate sheet 2 to compress the movable grate sheet 1, the pull bar 6 can be pulled by the compression adjustment mechanism, and then the rear grate sheet 2 is controlled to compress the movable grate sheet 1.

[0017] Such as figure 1 As shown, the compression adjustment mechanism includes a spring 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com