Ceramic color-sand real-stone paint and method for preparing same

A technology of real stone paint and colored sand, applied in the field of coatings, can solve the problems such as the inability of organic pigments to be washed by rain, the color and luster of colored sand is not firm, and the cost of easy decolorization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

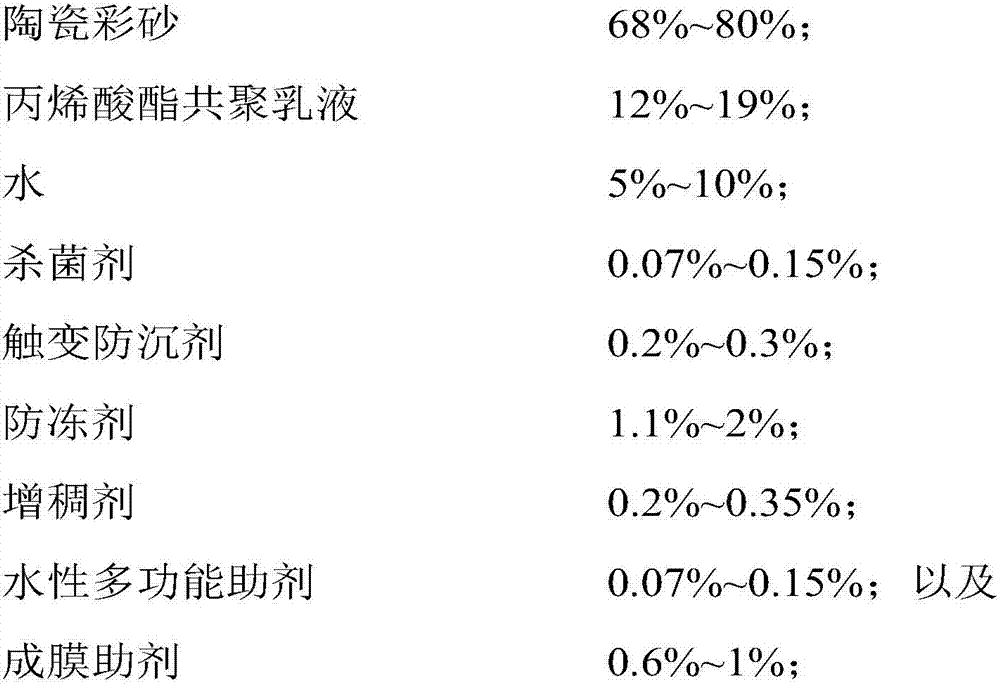

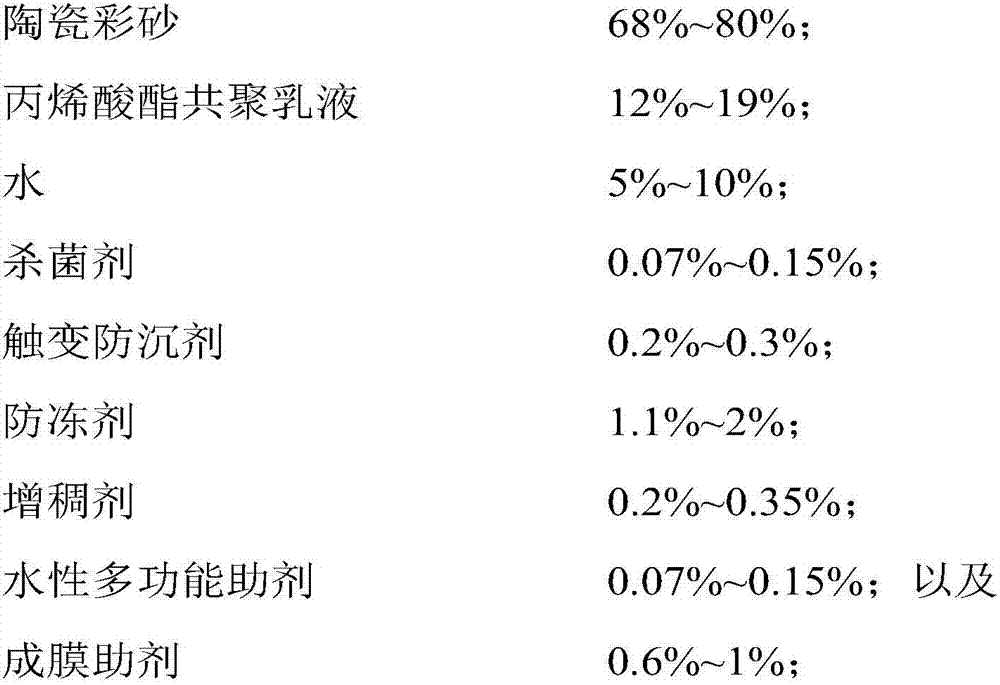

[0046] The embodiment of the present invention also provides a preparation method of ceramic colored sand real stone paint, which comprises the following steps:

[0047] S1. According to the above ratio, add water, bactericide, thixotropic anti-sedimentation agent, antifreeze agent, and thickener into the reaction kettle in sequence, and stir evenly at a low speed at a speed of 300-500 rpm.

[0048] The ceramic colored sand can be prepared according to the following preparation method:

[0049] Stir the quartz sand or clay, and the dyeing agent composed of pigments, binders and co-solvents evenly, place them in a rotary kiln at 1000-1500°C for 10-30 minutes, and cool to get the product. Among them, the binder is selected Aluminum dihydrogen phosphate, aluminum dihydrogen phosphate is made of phosphoric acid, aluminum hydroxide and water according to the mass ratio of 100:5~20:8~25 at 40~100°C for 2~10 hours, and the auxiliary solvent is anhydrous boric acid , the mass ratio o...

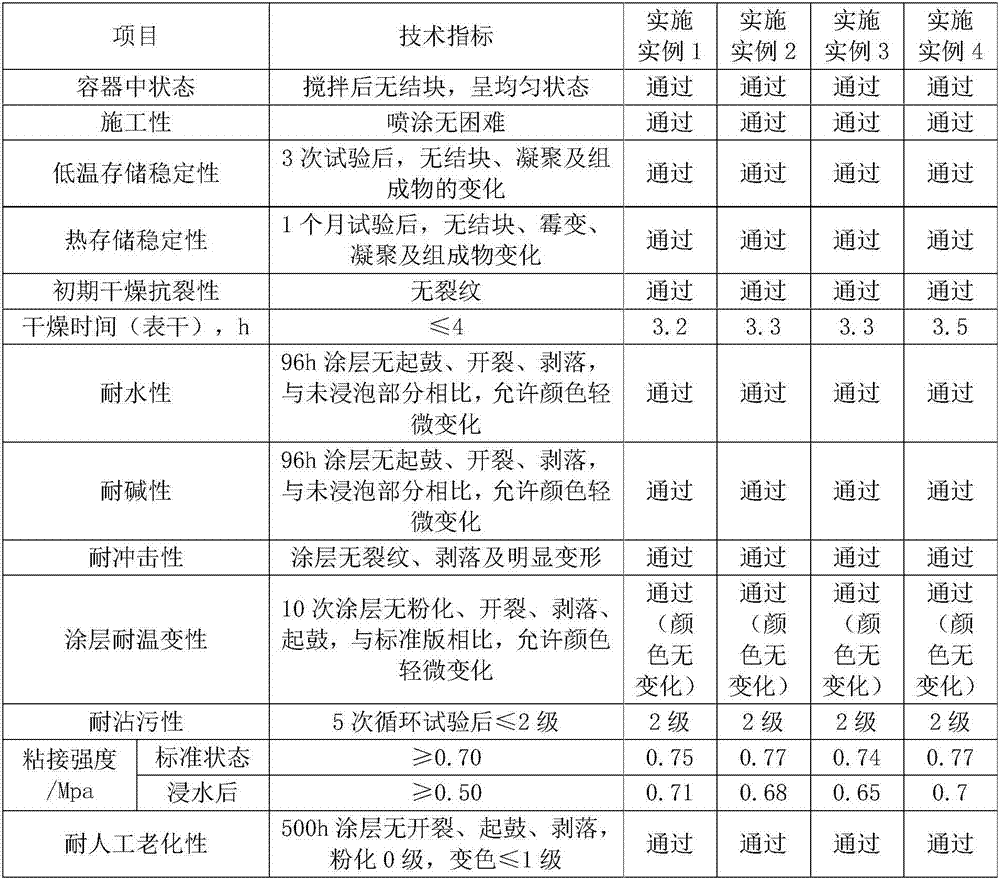

Embodiment 1

[0056] Embodiment 1 provides a kind of ceramic colored sand genuine stone paint, and its formula is as follows:

[0057] 75kg ceramic colored sand; 15kg pure acrylic emulsion (acrylate copolymer emulsion); 7kg deionized water; 0.1kg methylisothiazolinone (fungicide); 0.25kg modified bentonite (thixotropic anti-sedimentation agent); 1.5kg ethanol (antifreeze); 0.3kg alkali-swellable acrylic emulsion thickener (thickener); 0.1kg monoethanolamine (water-based multifunctional auxiliary agent); 0.75kg Texanol ester alcohol (film-forming auxiliary agent).

[0058] The ceramic colored sand is prepared according to the following preparation method:

[0059] Stir the quartz sand, and the dyeing agent composed of pigments, binders and co-solvents evenly, place them in a rotary kiln at 1200°C for 25 minutes, and cool to get it. Among them, the binders are aluminum dihydrogen phosphate, phosphoric acid Aluminum dihydrogen is made by stirring and reacting phosphoric acid, aluminum hydroxi...

Embodiment 2

[0066] Embodiment 2 provides a kind of ceramic colored sand genuine stone paint, and its formula is as follows:

[0067] 75kg Hongqiao mineral series ceramic colored sand; 15kg BASF ACRONAL 7015 (acrylate copolymer emulsion); 7kg deionized water; 0.1kg Rohm and Haas LXE (fungicide); (thixotropic anti-sedimentation agent); 1.5kg Rhodia FT-100 (antifreeze); 0.3kg Aqualon HBR250 (thickener); 0.1kg Dow AMP-95 (water-based multifunctional additive); 0.75kg Eastman OE300 (film-forming additive).

[0068] The ceramic colored sand real stone paint is prepared by using the raw materials in the above formula according to the following preparation method:

[0069] S201. According to the above ratio, add 7kg of deionized water, 0.1kg of Rohm and Haas LXE, 0.25kg of Xiaochao AC-603, 1.5kg of Rhodia FT-100, and 0.3kg of Aqualon HBR250 into the reaction kettle in sequence, Mix well on low speed at 400 rpm.

[0070] S202. Add 0.1 kg of Dow AMP-95 into the above reaction kettle, and stir at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com