A kind of method for electroconversion of magnesium chloride into high-purity magnesium oxide

A technology of magnesium chloride and magnesium oxide, which is applied in the field of electrolysis, can solve the problems of high energy consumption, high cost, and long process, and achieve the effects of high purity, energy saving, and anti-dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

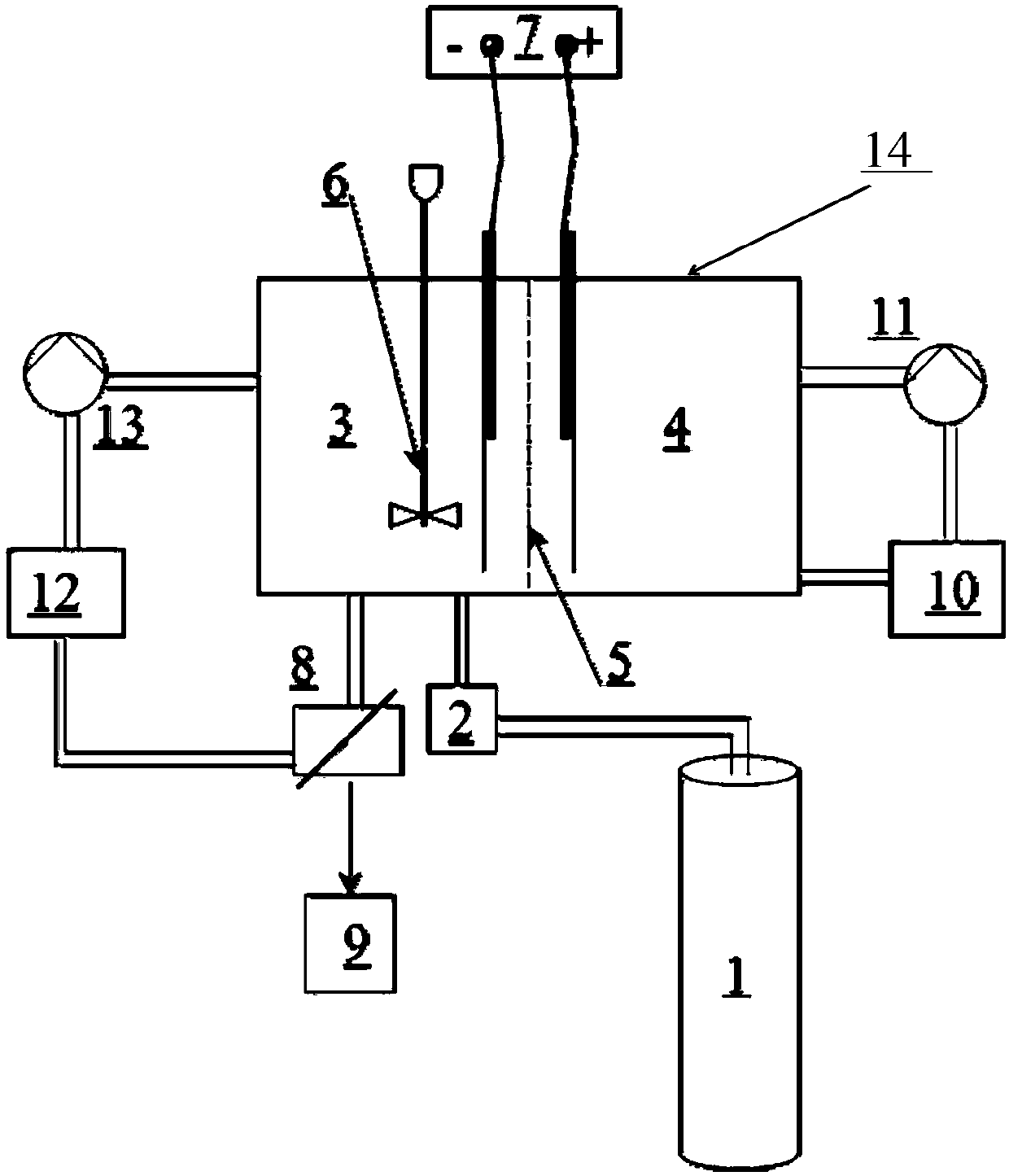

[0055] Present embodiment is converted into the method for high-purity magnesium oxide by magnesium chloride electricity, carries out according to the following steps:

[0056] Step 1: Carry out electrolysis to magnesium chloride aqueous solution, the process parameter of electrolysis is: temperature is 20 ℃, the voltage of electrolysis is 3V;

[0057] In described step 1, the mass concentration of described magnesium chloride aqueous solution is 50g / L;

[0058] Step 2: Introduce high-purity carbon dioxide gas into the cathode chamber 3 electrolyte in the cationic membrane electrolyzer with a flow rate of 20m 3 / h, the magnesium carbonate precipitation is directly generated in the cathode chamber 3 of the cationic membrane electrolyzer;

[0059] In the step 2, the high-purity carbon dioxide gas is introduced through the vent hole at the bottom of the cathode chamber 3 of the electrolytic cell.

[0060] Step 3: Stir the cathode chamber 3 of the cationic membrane electrolyzer,...

Embodiment 2

[0066] Present embodiment is converted into the method for high-purity magnesium oxide by magnesium chloride electricity, carries out according to the following steps:

[0067] Step 1: Carry out electrolysis to magnesium chloride aqueous solution, the process parameter of electrolysis is: temperature is 90 ℃, the voltage of electrolysis is 20V;

[0068] In described step 1, the mass concentration of described magnesium chloride aqueous solution is 500g / L;

[0069] Step 2: Introduce high-purity carbon dioxide gas into the cathode chamber 3 electrolyte in the cationic membrane electrolyzer with a flow rate of 90m 3 / h, the magnesium carbonate precipitation is directly generated in the cathode chamber 3 of the cationic membrane electrolyzer;

[0070] In the step 2, the high-purity carbon dioxide gas is introduced through the vent hole at the bottom of the cathode chamber 3 of the electrolytic cell.

[0071] Step 3: Stir the cathode chamber 3 of the cationic membrane electrolyze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com