Dynamic electronic mini-size unmanned weighing instrument of double-hole cantilever beam strain gauge

A strain gauge and cantilever beam technology, applied in the field of weighing, can solve the problems of no alarm function and easy damage to the strain gauge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

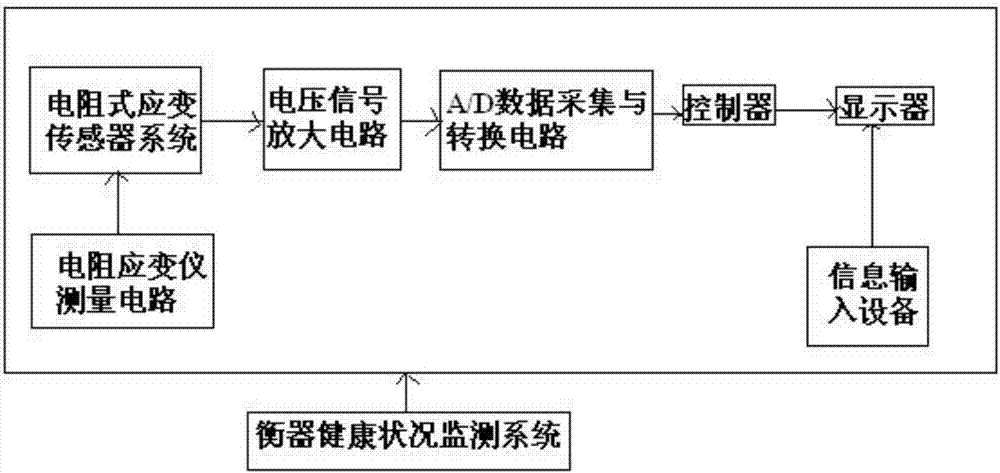

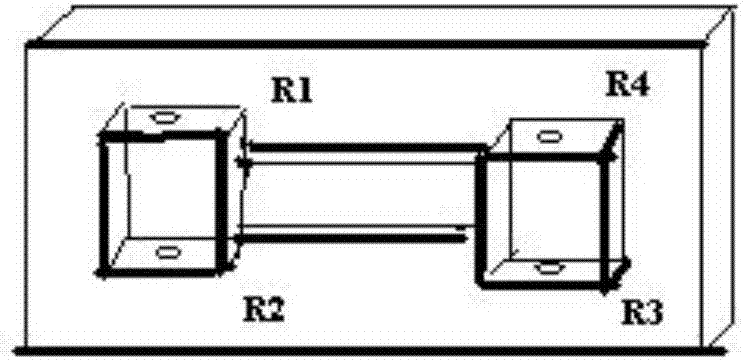

[0018] See attached figure 1 , a dynamic electronic small unmanned vehicle scale with double-hole cantilever beam strain gauge, which consists of a resistive strain sensor system, a voltage signal amplification circuit, an A / D data acquisition and conversion circuit, an MSP430F149 controller, a resistance strain gauge measurement circuit, and LCD1604 It consists of a display and a keyboard, wherein the resistance strain sensor system uses resistance strain gauges as the sensitive elements of the load cell, see attached figure 2 , The cantilever beam of the resistance strain gauge adopts a double hole beam structure, and two square holes are opened on the plate beam, and the resistance strain gauge is pasted on the inner wall of the two holes, so that the strain gauge is in the opposite stress zone. A total of four resistors R1, R2, R3 and R4 are pasted. When the deformation of R1 and R4 is tension, R2 and R3 are compression deformation. The four resistors form a differential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com