Method for improving breakdown strength and energy storage density of dielectric composite material

A technology of composite materials and breakdown strength, which is applied in the field of improving the breakdown strength and energy storage density of dielectric composite materials, can solve the problems of deterioration of electrical breakdown performance of composite films, improve interfacial compatibility, and improve dispersion controllability And the effect of stability and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] BaTiO 3 Hydroxylation: Weigh 3g of dried BaTiO 3 Put it into a three-necked round-bottomed flask, add 70ml of hydrogen peroxide, and ultrasonically disperse for half an hour. The reaction system is magnetically stirred in an oil bath at 106°C, and heated to reflux for 6h. After the reaction, cool to room temperature and centrifuge with a low-speed centrifuge (3000r, 10min). Then, it was centrifuged and washed twice with deionized water, and the obtained product was dried at 80° C. for 12 hours. Grinding to get BaTiO 3 -OH;

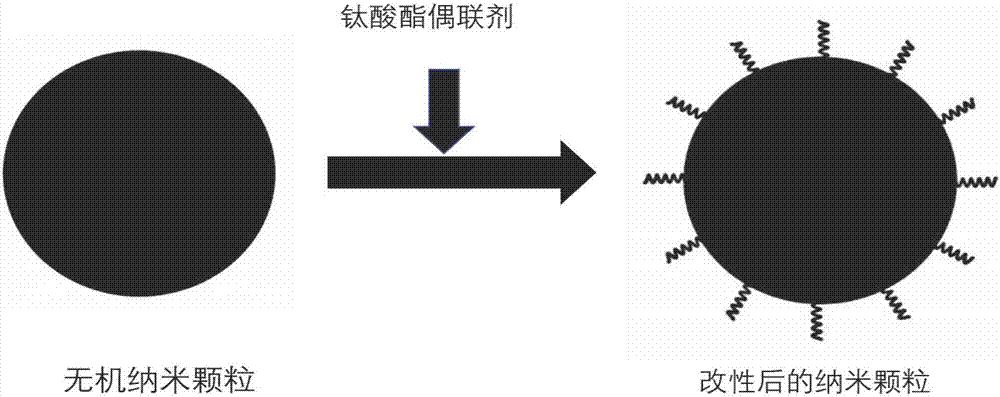

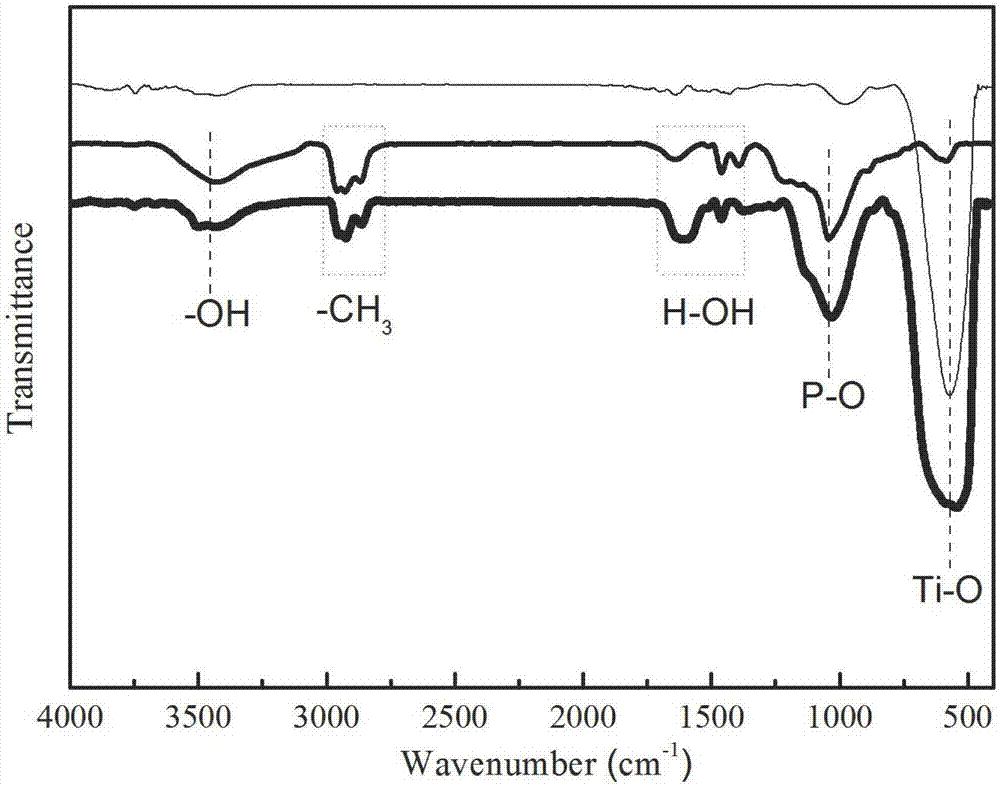

[0069] TC-2 surface coating modification: weigh 1g of BaTiO 3 -OH powder was placed in a three-necked round bottom flask, dissolved in 80ml of isopropanol, and stirred for 30min while ultrasonically to promote its dissolution. Then, 0.1ml of TC-2 was added dropwise with magnetic stirring and refluxed in an oil bath at 70°C for 2h. After the reaction was completed, it was cooled to The product was obtained by centrifugation at room temperature at...

Embodiment 2

[0072] BaTiO 3 Hydroxylation: Weigh 3g of dried BaTiO 3 Put it into a three-necked round-bottomed flask, add 70ml of hydrogen peroxide, and ultrasonically disperse for half an hour. The reaction system is magnetically stirred in an oil bath at 106°C, and heated to reflux for 6h. After the reaction, cool to room temperature and centrifuge with a low-speed centrifuge (3000r, 10min). Then, it was centrifuged and washed twice with deionized water, and the obtained product was dried at 80° C. for 12 hours. Grinding to get BaTiO 3 -OH;

[0073] TC-2 surface coating modification: weigh 1g of BaTiO 3 -OH powder was placed in a three-necked round bottom flask, dissolved in 80ml of isopropanol, and stirred for 30min while ultrasonically to promote its dissolution. Then, 0.1ml of TC-2 was added dropwise with magnetic stirring and refluxed in an oil bath at 70°C for 2h. After the reaction was completed, it was cooled to The product was obtained by centrifugation at room temperature at...

Embodiment 3

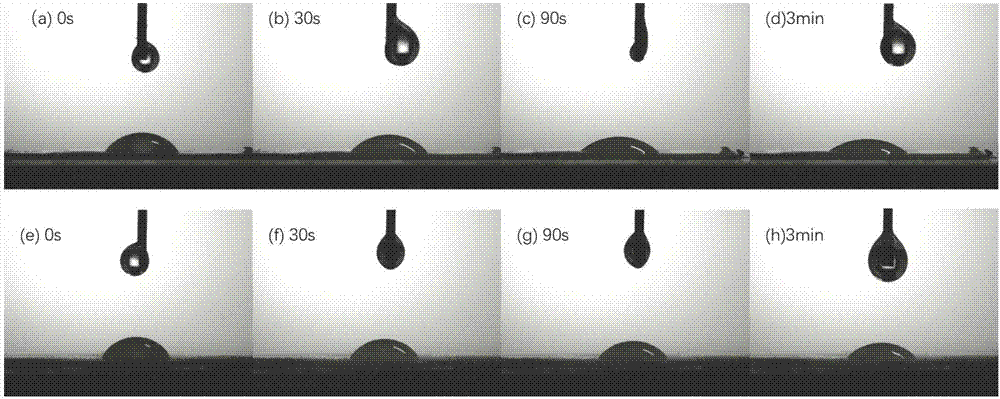

[0080] Weigh 0.01204g of unmodified BT nanoparticles, add it to 4ml DMF and ultrasonically disperse until the nanofiller forms a stable suspension in the solvent; add 0.5g PVDF to the above suspension while stirring, then place it at 30°C overnight Stir to dissolve completely. After stirring evenly, cast the film on a dry and clean glass plate. The composite film cast by solution is placed in an oven, and dried under the condition of 60-80° C., so that the solvent is completely volatilized. A composite thin film BT / PVDF with a filler content of 2vol% was obtained.

[0081] The BT-PVDF composite films with filling amounts of 2%, 4%, 6%, 8%, and 10% were prepared by changing the amount of BT particles added.

[0082] Scanning electron microscope observation of the composite film, such as Figure 4 As shown in (a), it was found that BT particles were seriously agglomerated in the PVDF matrix. The electrical breakdown performance and energy storage density of the composite film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com