Soldering lug and ultrasonic dental descaler comprising same

A dental scaler and welding chip technology, which is applied in cleaning teeth, using liquid cleaning methods, dentistry, etc., can solve the problems that the reliability of solder joints cannot be guaranteed, it is difficult to automate welding production, and the skills of welding personnel are required to be high. Achieve the effect of small package structure diameter, reliable welding quality, and solve ignition failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

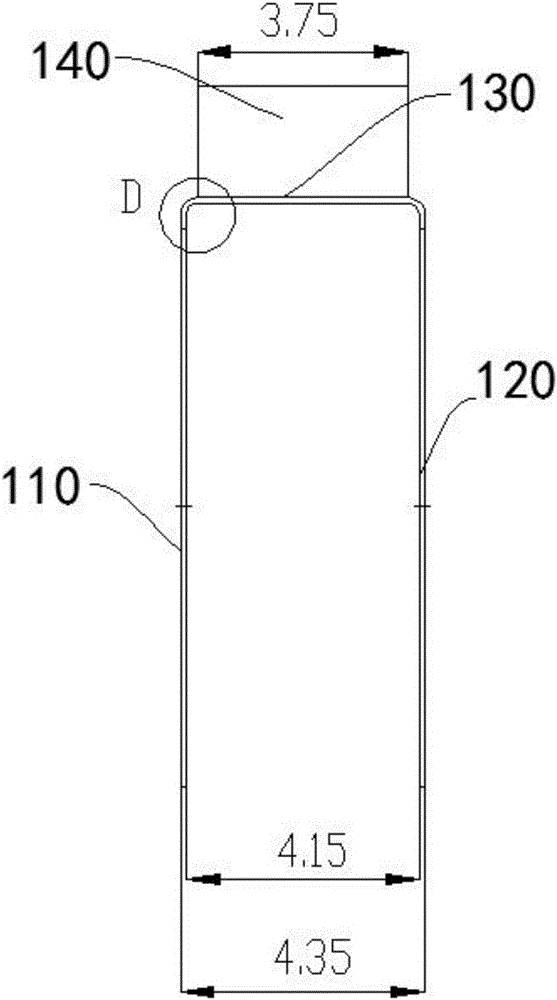

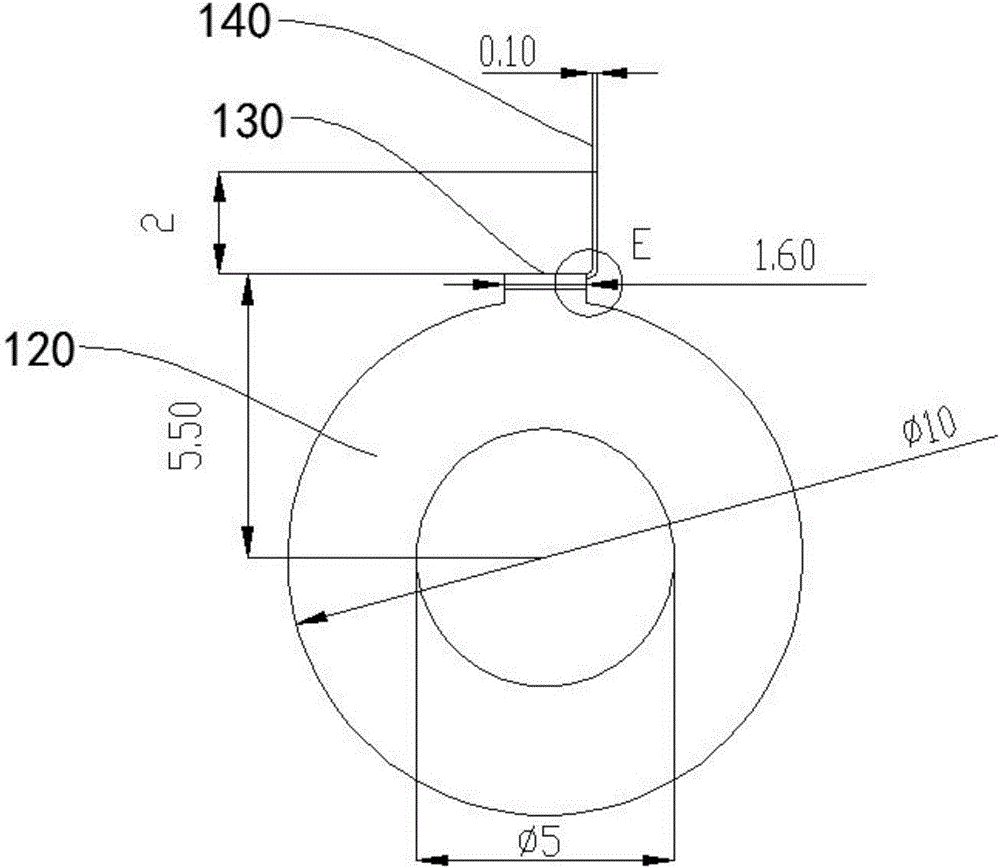

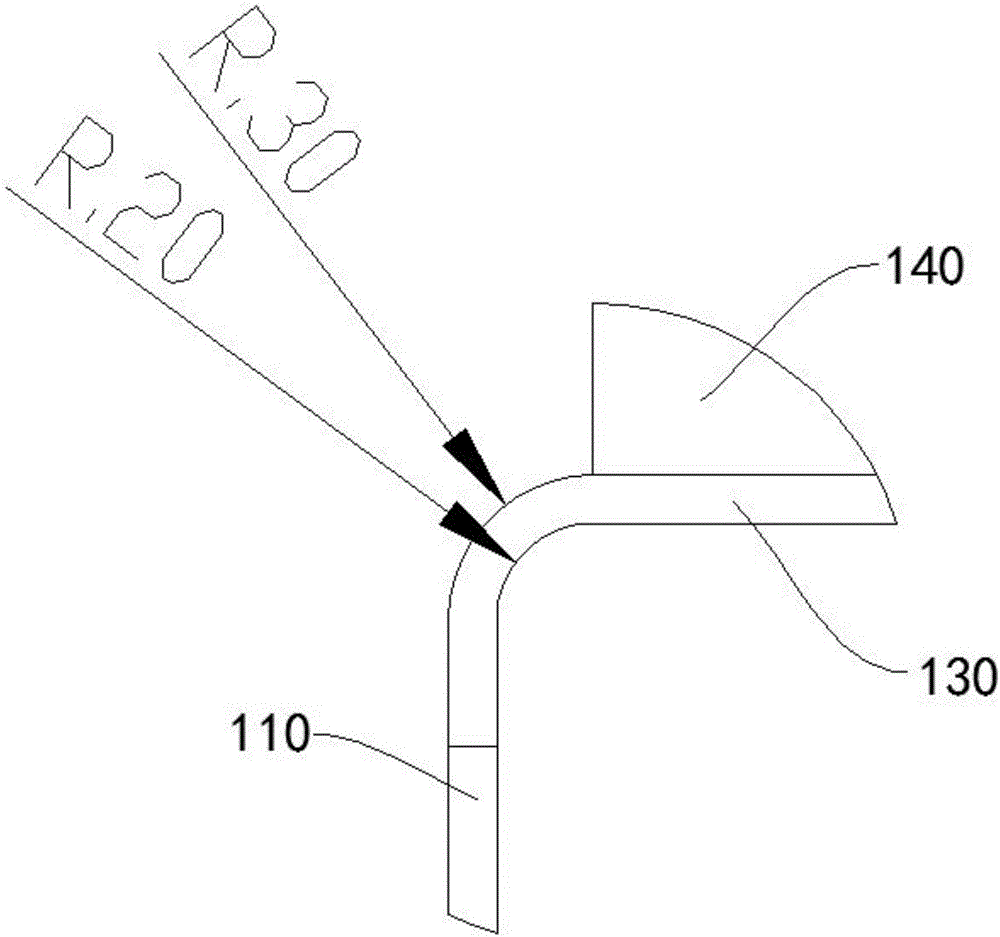

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a welding piece used in an ultrasonic scaler, the welding piece 1 includes a first connecting board 110 , a second connecting board 120 , a third connecting board 130 and a fourth connecting board 140 . The soldering piece 1 is processed by an integral molding process.

[0031] The left end of the first connecting plate 110 and the third connecting plate 130 are connected, and the second connecting plate 120 and the right end of the third connecting plate 130 are connected. When connected, the first connecting plate 110 and the second connecting plate 120 are located at the On the same side of the three connecting boards 130 , the first connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com