High-chromium type vanadium-titanium magnetic pellets and method for improving quality of high-chromium type vanadium-titanium magnetic pellets

A vanadium-titanium-magnetite concentrate and vanadium-titanium-magnetite technology are applied in the field of metallurgy and can solve the problems of lack of application of pellets entering the furnace, poor quality and metallurgical properties of high-chromium-type vanadium-titanium magnetite pellets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

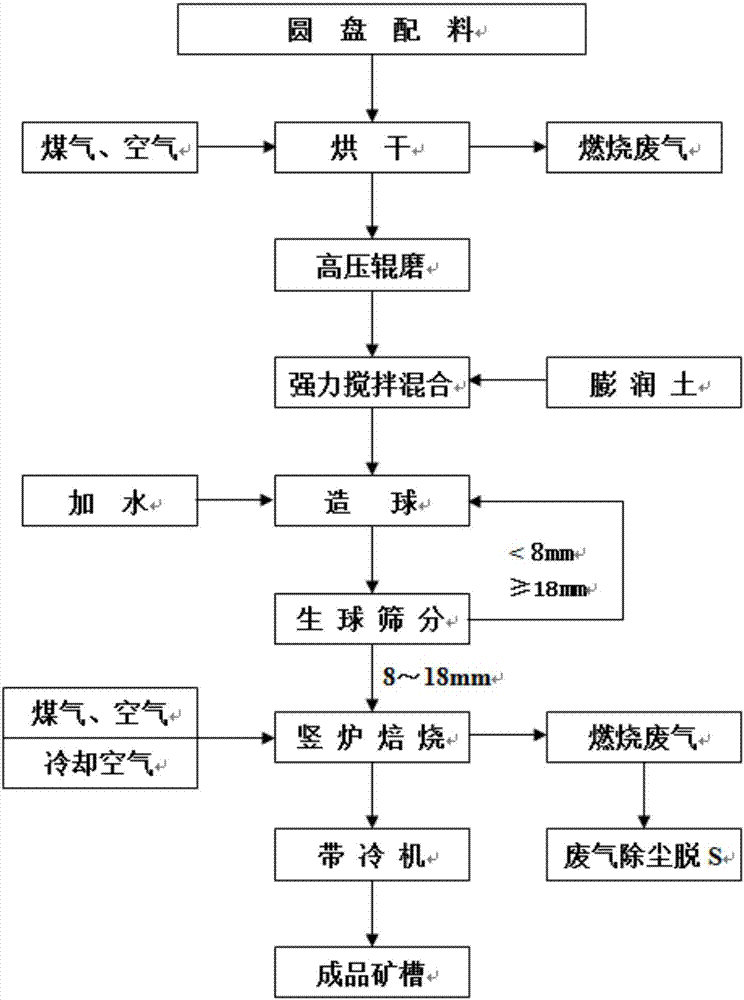

Image

Examples

Embodiment 1

[0047] Present embodiment provides a kind of method that improves high-chromium type vanadium-titanium magnetite pellet quality and comprises:

[0048] Mixing high-chromium vanadium-titanium magnetite concentrate and bentonite with a moisture mass percentage of 6-7% and bentonite according to the ratio of 98.4:1.5 to obtain a mixture;

[0049] Among them, the main components of high-chromium vanadium-titanium magnetite concentrate are calculated by mass percentage:

[0050] Cr 2 o 3 : 0.8%, TFe: 50%, Ti: 11%, V: 0.5%.

[0051] The mixture is pelletized, and the moisture mass percentage content of the green pellets after pelletizing is 9%;

[0052] Among them, pelletizing is carried out in a disk pelletizing machine, the rotating speed of the pelletizing machine is controlled at 6r / min, and the inclination angle of the pelletizing machine is controlled at 48.5°.

[0053] The raw balls are sieved and roasted successively to obtain cooked balls. After the green balls are scr...

Embodiment 2

[0057] The present embodiment provides a kind of method that improves high chromium type vanadium-titanium magnetite pellet quality, and the difference of this method and the method that embodiment 1 provides is, comprises:

[0058] Mixing high-chromium vanadium-titanium magnetite concentrate and bentonite with a moisture content of 6.5% in a ratio of 98.4:1.6 to obtain a mixture;

[0059] Among them, the main components of high-chromium vanadium-titanium magnetite concentrate are calculated by mass percentage:

[0060] Cr 2 o 3 : 1.0%, TFe: 52%, Ti: 11.5%, V: 0.55%.

[0061] The mixture is pelletized, and the moisture mass percentage content of the green pellets after pelletizing is 9.5%;

[0062] Among them, pelletizing is carried out in a disk pelletizing machine, the rotating speed of the pelletizing machine is controlled at 7r / min, and the inclination angle of the pelletizing machine is controlled at 50°.

[0063] The raw balls are sieved and roasted successively to o...

Embodiment 3

[0067] The present embodiment provides a kind of method that improves high chromium type vanadium-titanium magnetite pellet quality, and the difference of this method and the method that embodiment 1 provides is, comprises:

[0068] Mixing high-chromium vanadium-titanium magnetite concentrate and bentonite with a moisture content of 7% in a ratio of 98.4:1.7 to obtain a mixture;

[0069] Among them, the main components of high-chromium vanadium-titanium magnetite concentrate are calculated by mass percentage:

[0070] Cr 2 o 3 : 1.1%, TFe: 55%, Ti: 12%, V: 0.6%.

[0071] The mixture is pelletized, and the moisture content of the green pellets after pelletizing is 10%;

[0072] Among them, pelletizing is carried out in a disk pelletizing machine, the rotating speed of the pelletizing machine is controlled at 8r / min, and the inclination angle of the pelletizing machine is controlled at 51.5°.

[0073] The raw balls are sieved and roasted successively to obtain cooked balls. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com