Dip tank of fabric dip dyeing system

A technology of soaking tank and cloth, applied in the field of textile manufacturing, can solve the problems of uneven color block of fabric, unreasonable structure design of soaking tank, uneven concentration of dye solution, etc., and achieve the effect of increasing concentration and improving dyeing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

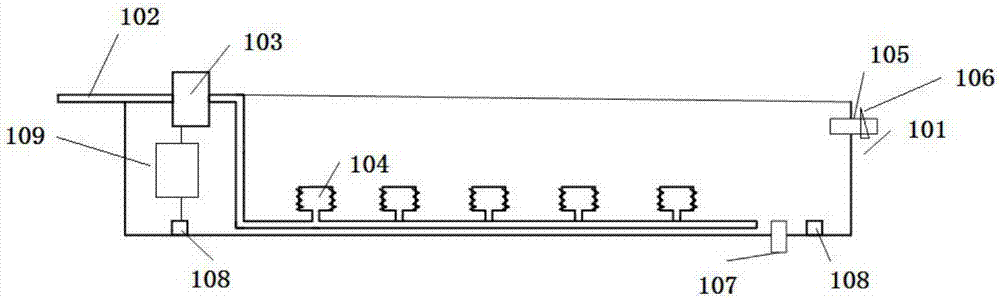

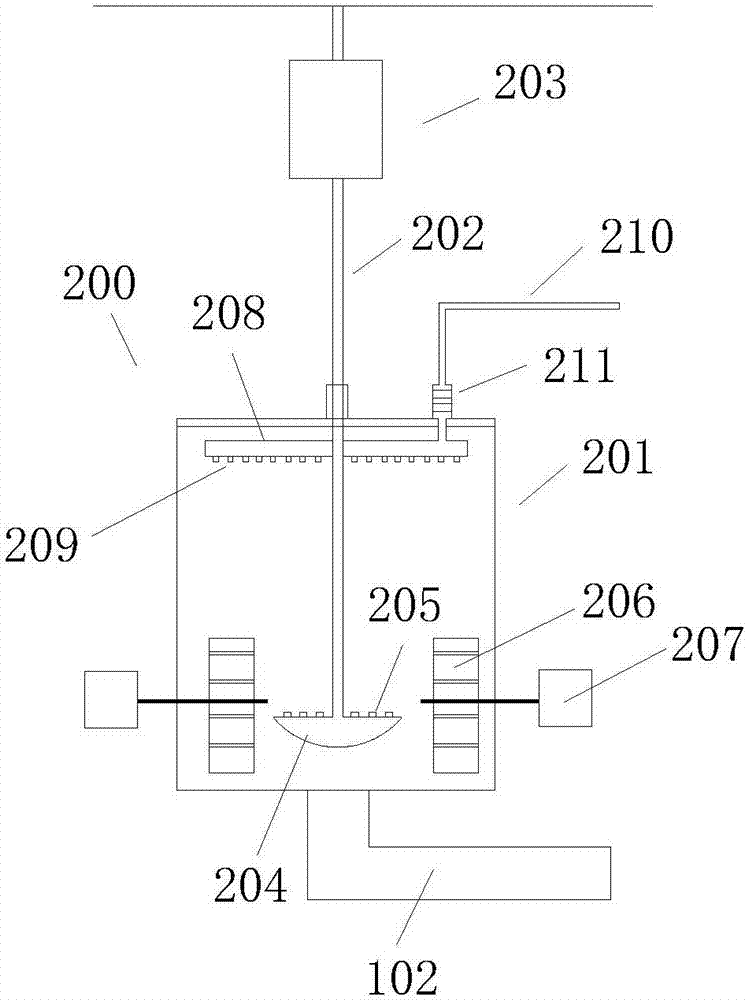

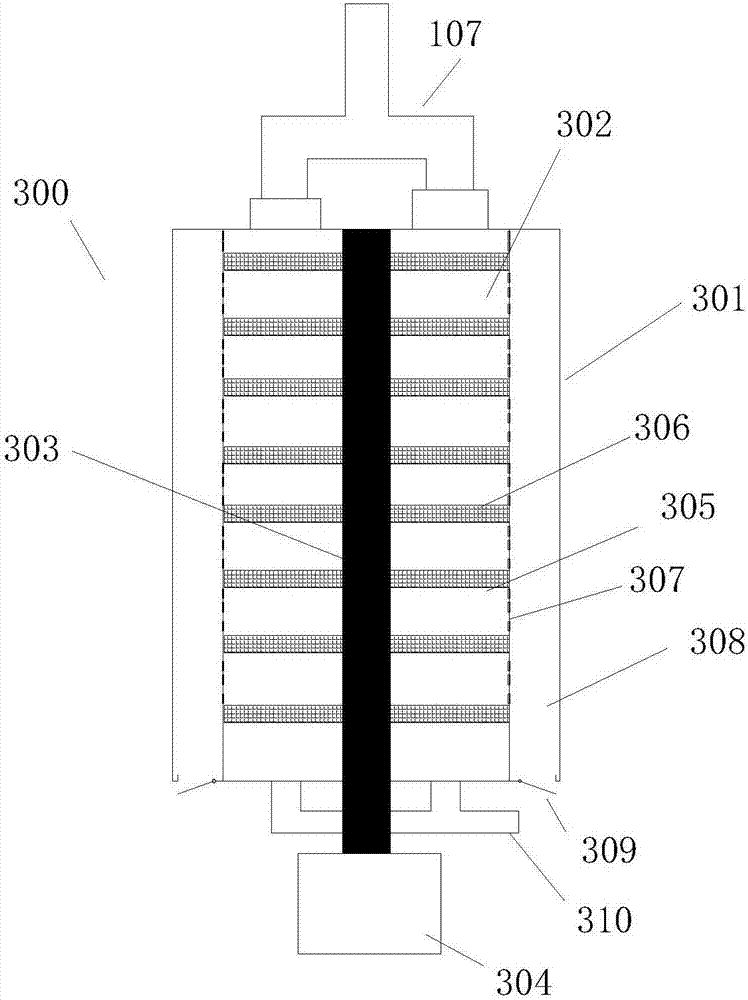

[0014] Example: The soaking tank of the cloth dip dyeing system is constituted as figure 1 As shown, the immersion tank 101 is included. The immersion tank 101 is provided with a dye pipe 102, the end of the dye pipe 102 is provided with a volumetric pump 103, and the dye pipe 102 is provided with a plurality of dye discharge ports 104; on the upper part of the immersion tank 101 There is a water inlet 105, a solenoid switch valve 106 is arranged at the water inlet 105, a drain 107 is arranged at the bottom of the soaking tank 101; a dye concentration detector 108 is arranged at the bottom of the soaking tank 101, and the dye concentration detector 108 is connected with The controller 109 is connected to the displacement pump 103 and the electromagnetic switch valve 106;

[0015] Working principle: The dye in the dye pipeline is transferred to the dye discharge port by the volumetric pump, and flows from the dye discharge port to the soaking tank. The soaking tank is immersed with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap