High-frequency high-speed copper-clad laminate manufacturing method and copper-clad laminate

A manufacturing method and technology of copper-clad laminates, which are applied in chemical instruments and methods, circuit substrate materials, and other household appliances, can solve problems such as high dielectric constant, insufficient dimensional stability, and large dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

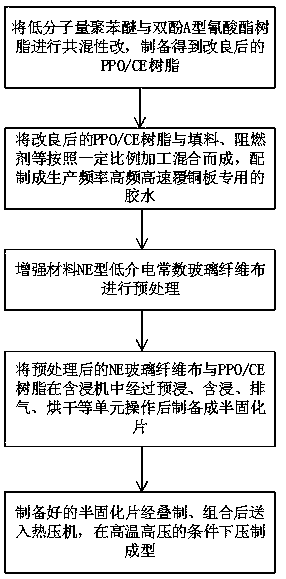

Method used

Image

Examples

preparation example Construction

[0033] Preparation of prepregs: The treated NE glass fiber cloth and PPO / CE resin are prepared into prepregs after unit operations such as pre-impregnation, impregnation, exhaust, and drying in an impregnation machine.

[0034] Hot pressing molding: The prepared prepregs are stacked and combined, then sent to a hot press, and pressed and formed under high temperature and high pressure conditions.

[0035] The dielectric constant DK is the ratio of the capacitance when the electrodes are filled with a certain substance to the capacitance of a vacuum capacitor with the same structure, and usually indicates the ability of a certain material to store electrical energy. The current direction of the electrical signal passing through the printed board is usually positive and negative alternately, which is equivalent to the process of continuously charging and discharging the substrate. In interchange, the capacitance will affect the signal transmission speed. And this effect is more...

Embodiment 1

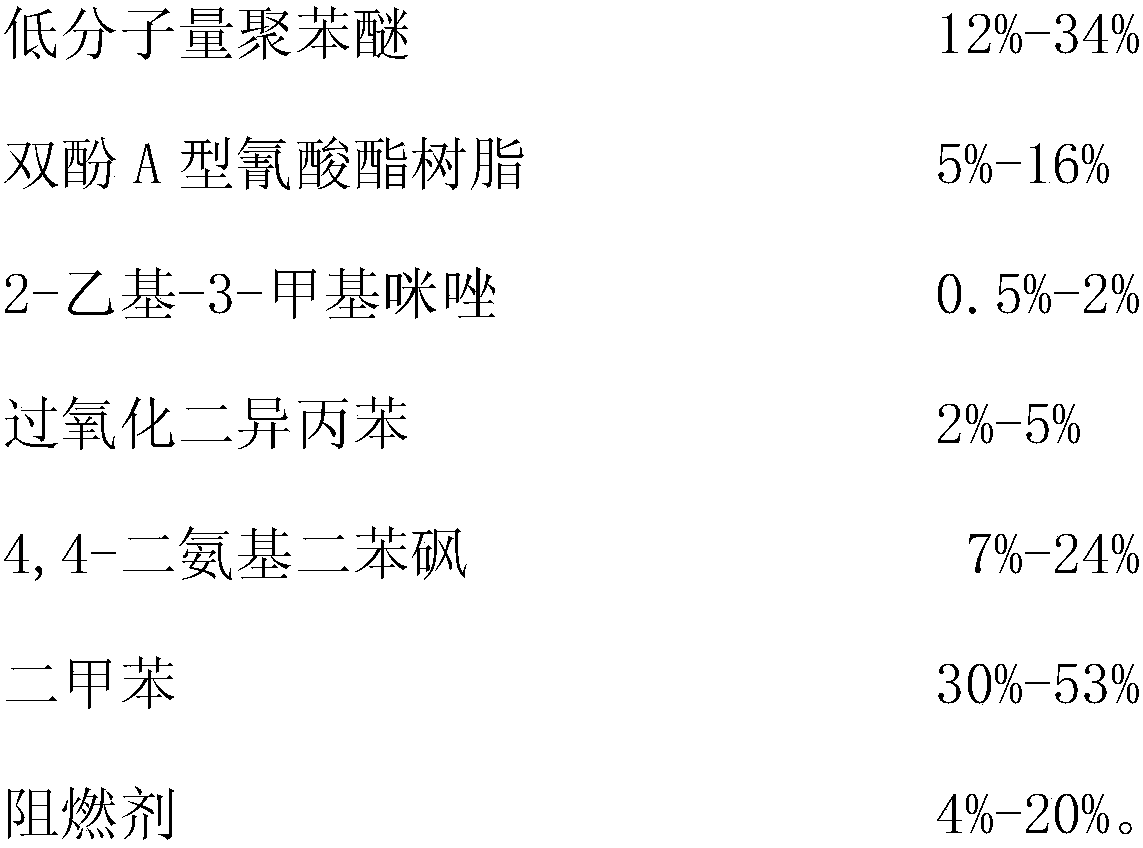

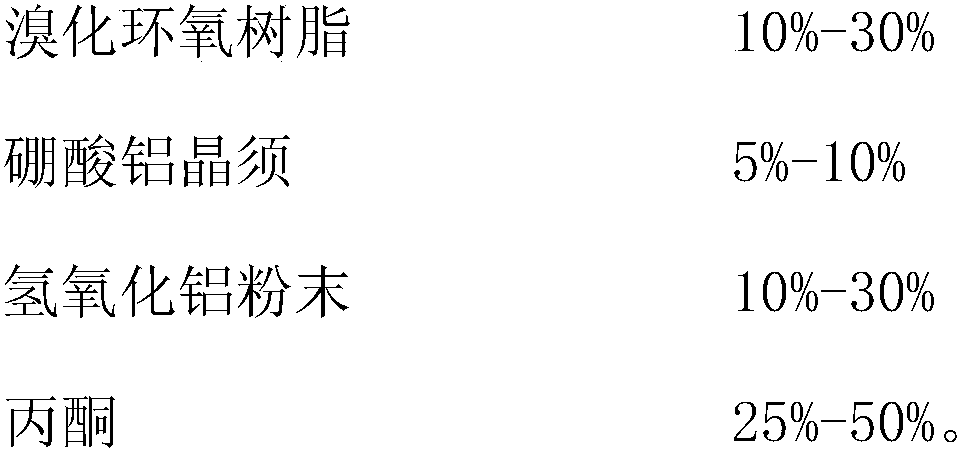

[0046] Put 12% low molecular weight polyphenylene ether, 10% bisphenol A cyanate resin and 53% xylene into a container, stir at 100°C until the solution is transparent; stop heating, and cool the solution to 60°C; Then add 5% dicumyl peroxide, 1% 2-ethyl-3-methylimidazole, 15% 4,4-diaminodiphenyl sulfone, 0.4% brominated epoxy resin, 0.4% aluminum borate crystal Whiskers, 1.0% aluminum hydroxide powder, and 2.2% acetone were heated and stirred under reflux at 130° C. for 2 hours, and then cooled to room temperature. The measured dielectric constant is 3.2, which meets the requirements.

Embodiment 2

[0048] Put 20% low molecular weight polyphenylene ether, 15% bisphenol A cyanate resin and 42% xylene into a container, stir at 100°C until the solution is transparent; stop heating, and cool the solution to 60°C; Then add 2% dicumyl peroxide, 0.5% 2-ethyl-3-methylimidazole, 12% 4,4-diaminodiphenyl sulfone, 1.2% brominated epoxy resin, 1% aluminum borate crystal Whiskers, 2% aluminum hydroxide powder, and 4.3% acetone were heated and stirred under reflux at 130° C. for 2 hours, and then cooled to room temperature. The measured dielectric constant is 3.0, which meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com