III-nitride nanowire led with strain modified surface active region and method of making thereof

A technology of active regions and nanowires, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low efficiency of light-emitting diodes and reduced efficiency of photon recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

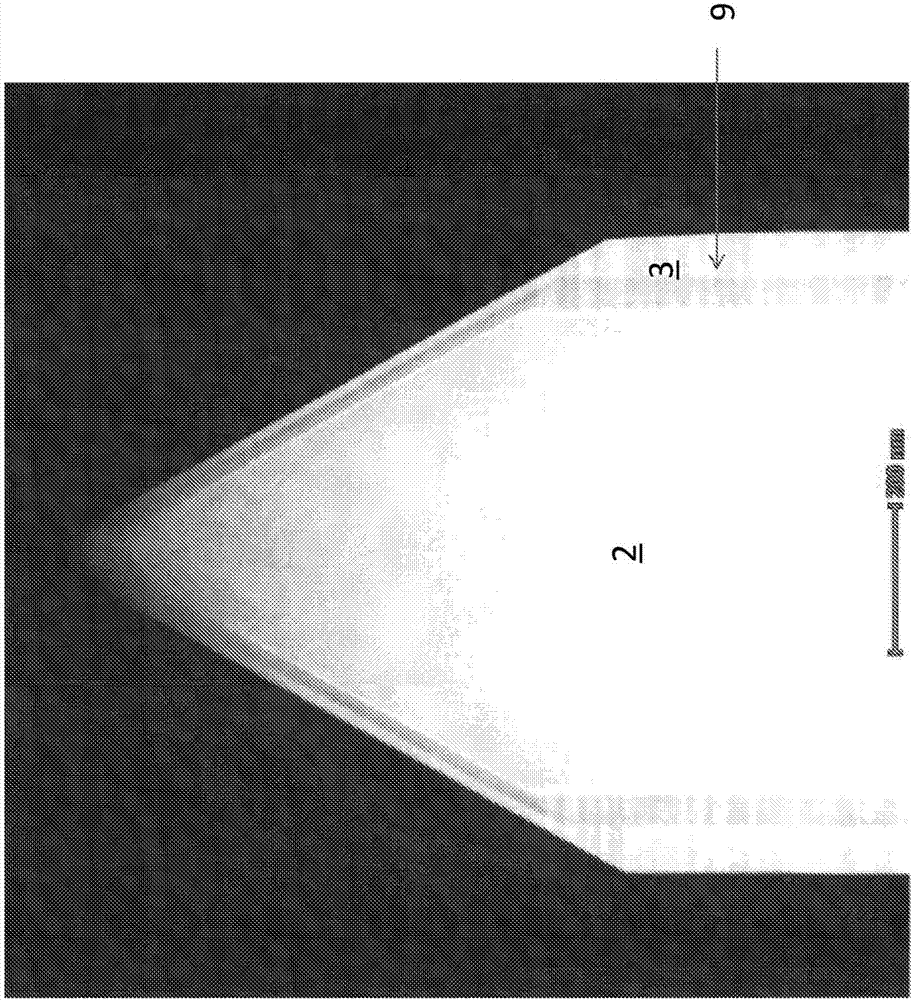

[0013] In one embodiment, the active area shell is formed on a non-uniform surface such that the active area shell has a non-uniform profile (e.g., non-vertical radial sidewalls and / or a gradient in the horizontal direction with respect to the vertical direction). uneven thickness that varies with height). This "corrugated" surface reduces or eliminates defects (such as stack-up defects) in the outer shell.

[0014] Formation of an active region shell comprising one or more In(Al)GaN / (Al)GaN quantum wells on a non-uniform surface results in the formation of an indium-rich In(Al)GaN region by self-assembly during formation of the active region (eg InGaN or InAlGaN regions with more than 10 atomic percent indium, such as 15 to 35 atomic percent indium). Depending on the indium content of the regions, it is believed that these indium-rich regions are responsible for longer wavelength spectral regions (e.g., green to yellow 495-590 nm peak emission wavelength region and / or orange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com