Thin-film transistor, manufacturing method thereof, array substrate and display device

A technology of thin film transistors and manufacturing methods, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of limiting the application of low-temperature polysilicon films and high leakage currents, and achieve reduced leakage currents, increased potential differences, and improved electrical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and points of the embodiments of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments. Obviously, the described embodiments are part of the embodiments of the present invention, not all Example. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention. It should be noted that the same reference numerals in the drawings all refer to the same components. Also, detailed descriptions of known arts will be omitted if they are unnecessary to illustrate the features of the present invention.

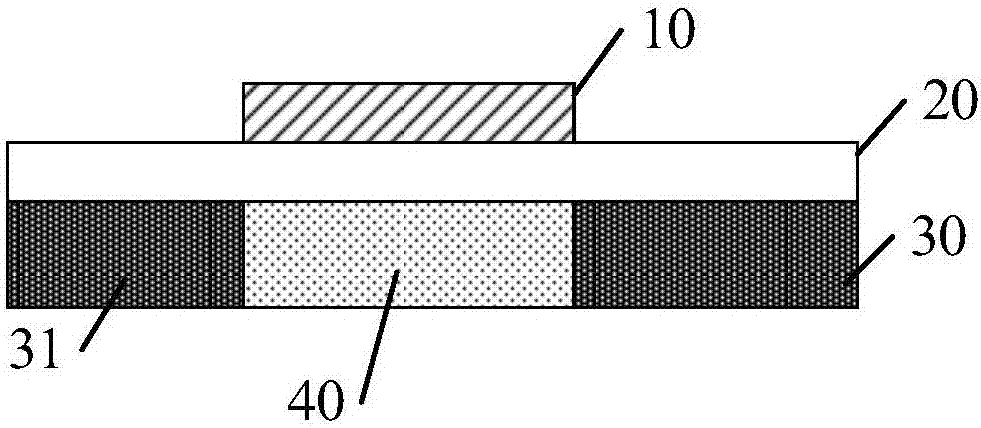

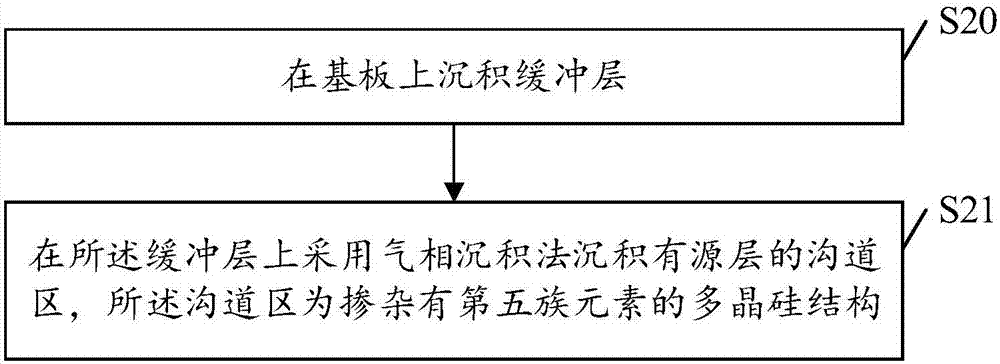

[0031] A schematic diagram of a partial structure of a thin film transistor provided by the present invention is as follows: figure 1 As shown, the active layer of the thin film transis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com