PTC assembling machine

A technology of assembling machine and assembling device, which is applied in the direction of assembling machine, mechanical equipment, material gluing, etc., can solve the problems of irregular arrangement of ceramic sheets, increase production cost, low production efficiency, etc., so as to reduce labor cost input and save production cost , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

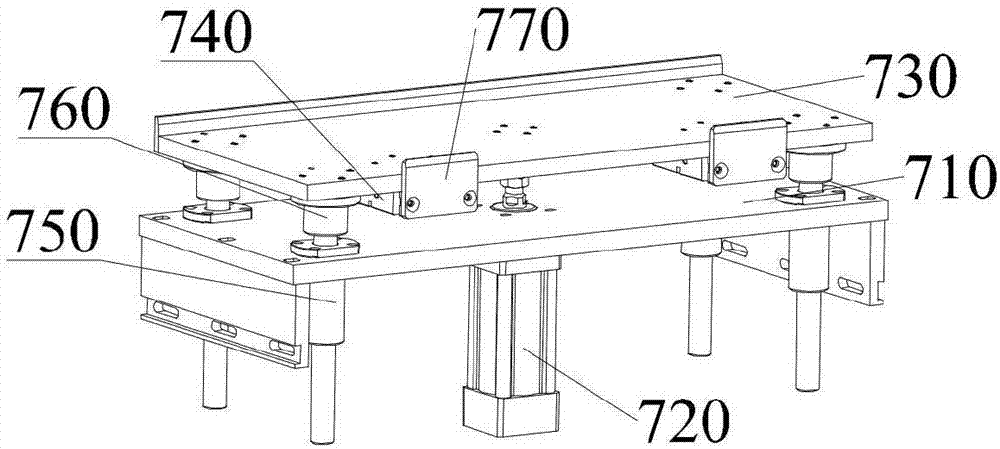

[0036] For clarity in the following instructions, please refer to figure 1 , the direction from the top of the machine 100 toward the bottom is defined as downward, and the direction from the bottom of the machine 100 toward the top is defined as upward.

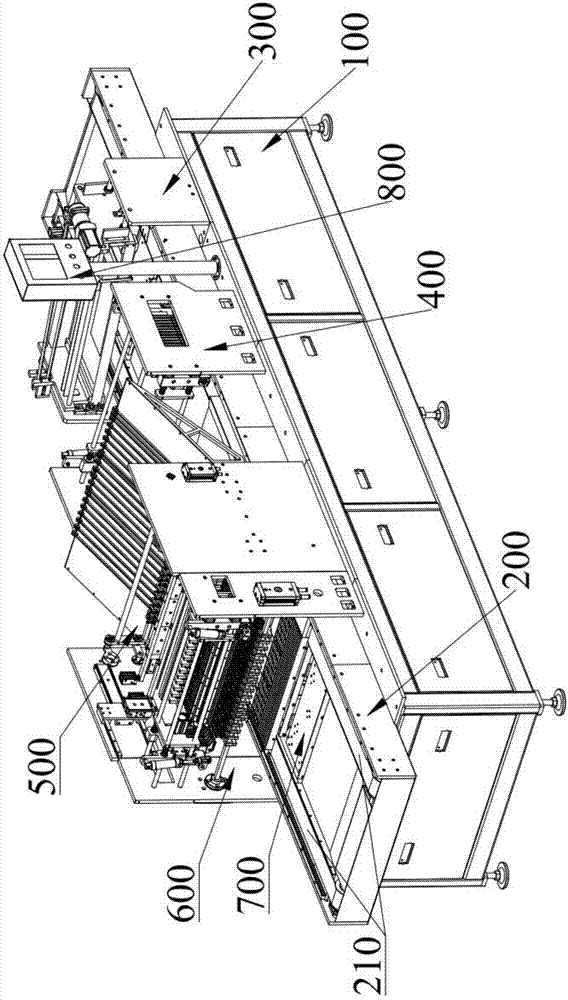

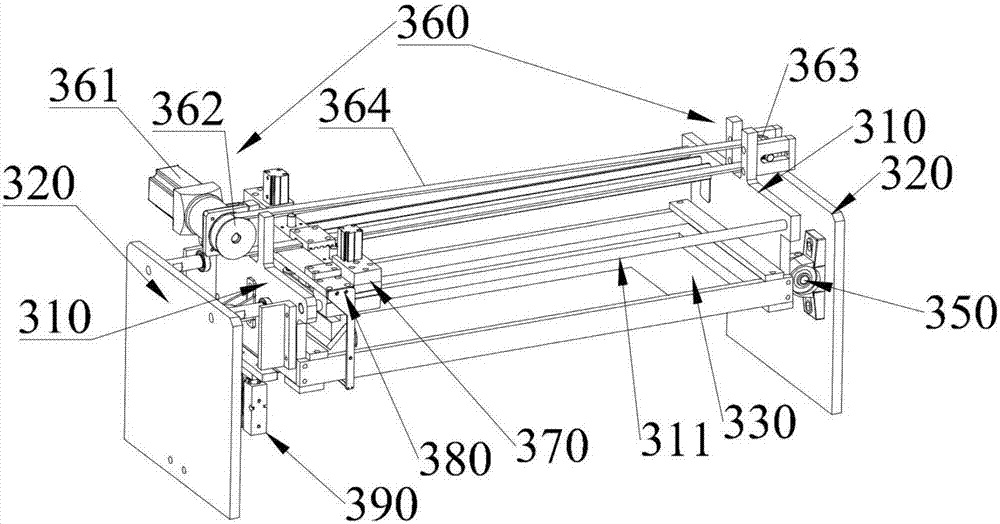

[0037] This embodiment provides a PTC assembly machine. Please refer to figure 1 As shown, it is a schematic structural diagram of the PTC assembly machine in the embodiment. The PTC assembly machine includes a machine platform 100, a transportation device 200, an electrode strip glue brushing device 300, an electrode strip spacing device 400, a ceramic sheet material splitting and assembly device 500, and an electrode strip assembly device 600. The length direction is set on the top surface of the machine 100, the electrode strip glue brushing device 300, the electrode strip spacing device 400, the ceramic sheet material distribution and assembly device 500, and the electrode strip assembly device 600 follow the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com