Medium and long chain fat emulsion injection containing olive oil and preparation method of medium and long chain fat emulsion injection

A long-chain fat emulsion and injection technology, applied in the field of medicine, can solve the problems of poor stability, destruction of the emulsion system, and the need to reduce inflammatory response, so as to improve the stability and drug safety, optimize the preparation process, enhance the The effect of emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

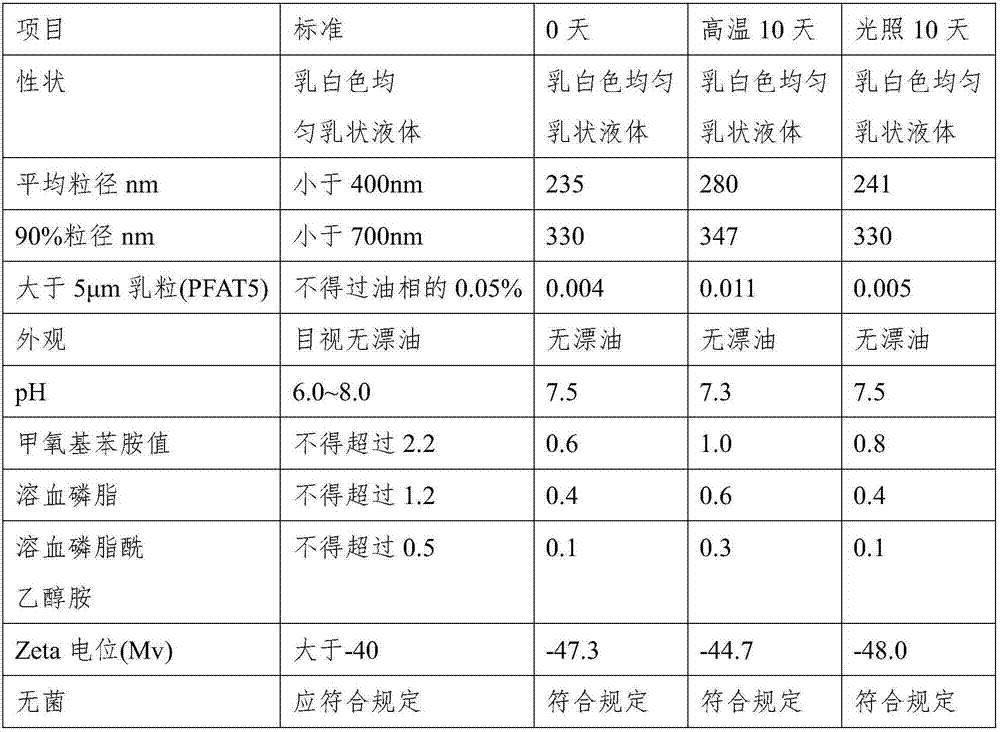

Embodiment 1

[0034] Oil phase preparation: under nitrogen protection, 120 g of refined olive oil, 40 g of soybean oil for injection, and 40 g of medium-chain triglycerides were added to the container. Heat it in a water bath to 65°C, add 9 g of refined egg yolk phospholipids under high-speed stirring at 6000 rpm, and disperse it to prepare an oil phase.

[0035]Water phase preparation: put 751.6g of 67°C water for injection in another container, add 25g of glycerin for injection, 0.225g of sodium oleate, and 1880.225g of poloxamer, stir and mix well, and filter through a 0.45μm filter membrane to prepare an aqueous phase .

[0036] Colostrum preparation: under nitrogen protection, pour the oil phase into the water phase under high-speed stirring at 6000 rpm and stir for 15 minutes to prepare colostrum. Rapidly cool down to about 30°C and perform high-pressure homogenization.

[0037] Homogenization: In a closed container and under nitrogen protection, transfer the prepared colostrum into...

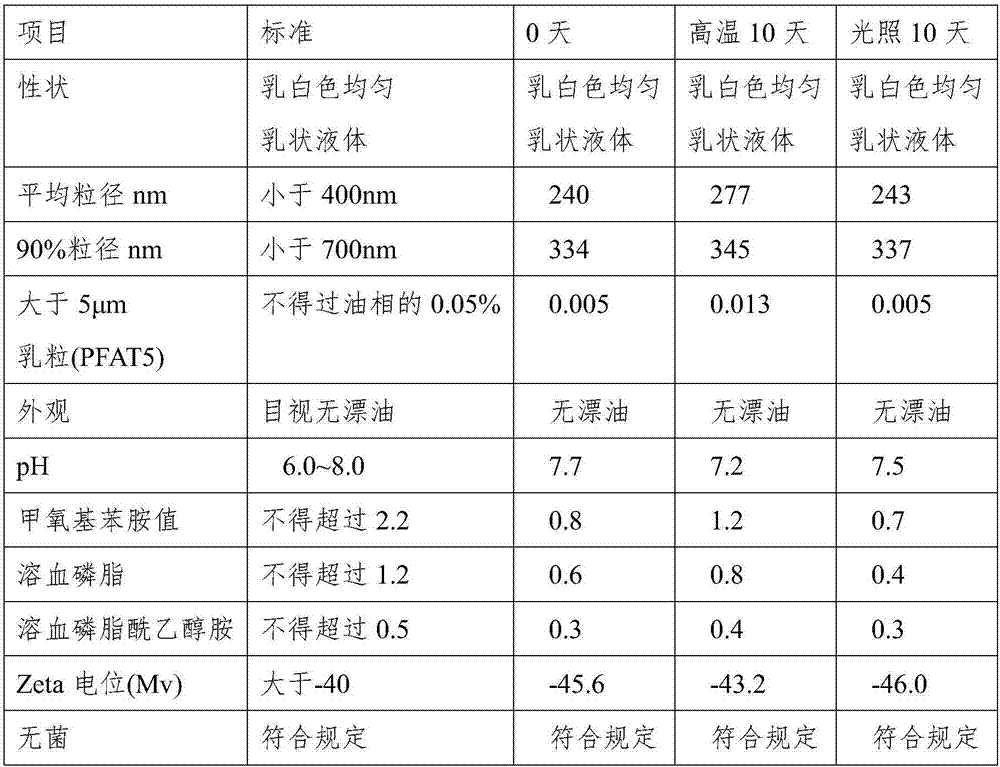

Embodiment 2

[0046] Oil phase preparation: under nitrogen protection, 160 g of refined olive oil, 20 g of soybean oil for injection, and 20 g of medium-chain triglycerides were added to the container. Heat it in a water bath to 70° C., add 12 g of refined egg yolk phospholipids under high-speed stirring at 8000 rpm, and disperse it to prepare an oil phase.

[0047] Water phase preparation: put 750.9g of 67°C water for injection into the container, add 22.5g of glycerin for injection, 0.3g of sodium oleate, and 1880.3g of poloxamer, stir and mix well, and filter through a 0.45μm filter membrane to prepare water Mutually.

[0048] Colostrum preparation: Under nitrogen protection, pour the oil phase into the water phase and stir for 15 minutes under high-speed stirring at 15,000 rpm to make colostrum, quickly cool down to about 40°C and perform high-pressure homogenization.

[0049] Homogenization: In a closed container and under the protection of nitrogen, transfer the prepared colostrum in...

Embodiment 3

[0058] Preparation of the oil phase: under nitrogen protection, 180 g of refined olive oil, 10 g of soybean oil for injection, and 10 g of medium-chain triglycerides were added to the container. Heat it in a water bath to 68° C., add 15 g of refined egg yolk phospholipids under high-speed stirring at 10,000 rpm, and disperse it to prepare an oil phase.

[0059] Water phase preparation: put 742.1g of 69°C water for injection in another container, add 28.1g of glycerin for injection, 0.375g of sodium oleate, and 1880.375g of poloxamer, stir and mix well, and filter through a 0.45μm filter membrane to prepare water Mutually.

[0060] Colostrum preparation: Under nitrogen protection, pour the oil phase into the water phase and stir for 15 minutes under high-speed stirring at 20,000 rpm to make colostrum, quickly cool down to about 45°C and perform high-pressure homogenization.

[0061] Homogenization: In a closed container and under nitrogen protection, transfer the prepared colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com