Layered washing machine

A washing machine, a layered technology, applied in the field of washing machines, can solve the problems of inability to sort and wash, waste water, electricity, time, and clothes are not clean, and achieve the effect of improving cleanliness, not easy to entangle, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

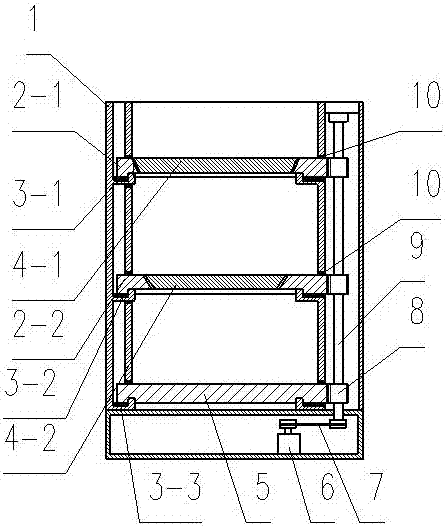

[0014] Such as figure 1 , 2 As shown, washing tub 1, motor 6, belt 7, the bottom pulsator assembly of the washing machine includes bottom pulsator 5, bottom sealing pad 3-3, two intervals are arranged on the upper end of the bottom pulsator assembly of washing tub 1 The middle layer pulsator assembly, wherein the first layer middle pulsator assembly includes the first layer pulsator support 2-1 and the first layer pulsator 4-1 supported on the washing tub 1, the first layer pulsator The center of the wheel support 2-1 is a tapered hole with a small bottom and a big top, the wall of the tapered hole has connecting teeth, the outer wall of the first layer of wave wheel support 2-1 has connecting teeth; the first layer of wave wheel 4-1 is a The taper hole of the wheel support 2-1 matches the lower small upper large cone, and its conical outer wall has connecting teeth, so that the wave wheel of the first layer of wave wheel 4-1 is put into the cone of the first layer of wave wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com