Hole drilling device used for identification signboard machining and operation method of hole drilling device

A drilling device and signage technology, applied in positioning devices, driving devices, boring/drilling and other directions, can solve the problems of high labor intensity of operators, low drilling hole position accuracy, and poor drilling quality, etc. Achieve the effect of enhancing drilling quality, improving drilling efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

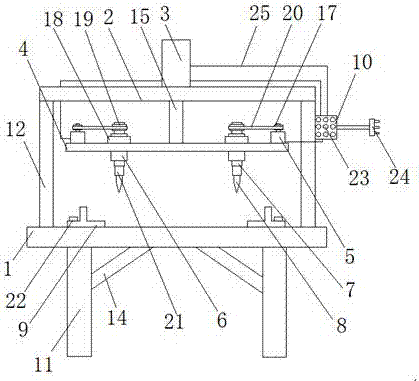

[0022] Example 1:

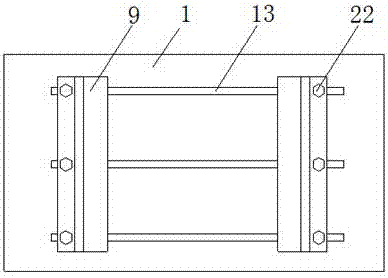

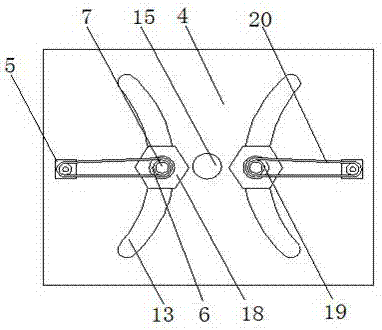

[0023] A drilling device for processing identification signs, comprising an operating table 1, a top plate 2, a cylinder 3, an adjusting plate 4, a motor 1, a fixing ring 6, a transmission shaft 7, a drill bit 8, a limit block 9 and a controller 10. It is as follows: the operating table 1 is arranged on the bracket 11, and the operating table 1 is provided with a column 12 and a limit groove 13, the top plate 2 is arranged on the column 12, and the cylinder 3 is arranged on the top plate 2 on the cylinder 3, a piston rod 15 is arranged on the cylinder 3, the regulating plate 4 is arranged on the piston rod 15, and an regulating groove 16 is arranged on the regulating plate 4, and the motor 5 is arranged on the regulating plate 4, And a driving wheel 17 is arranged on the motor 5, the fixing ring 6 is arranged in the adjusting groove 16 through the positioning nut 18, the transmission shaft 7 is arranged in the fixing ring 6, and the transmission shaft 7 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap