Copper electroplating solution, method for electroplating copper and method for forming copper cylinder

A copper electroplating solution and copper electroplating technology, applied in the field of copper electroplating solution, can solve the problems of increasing electroplating time and improving electroplating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

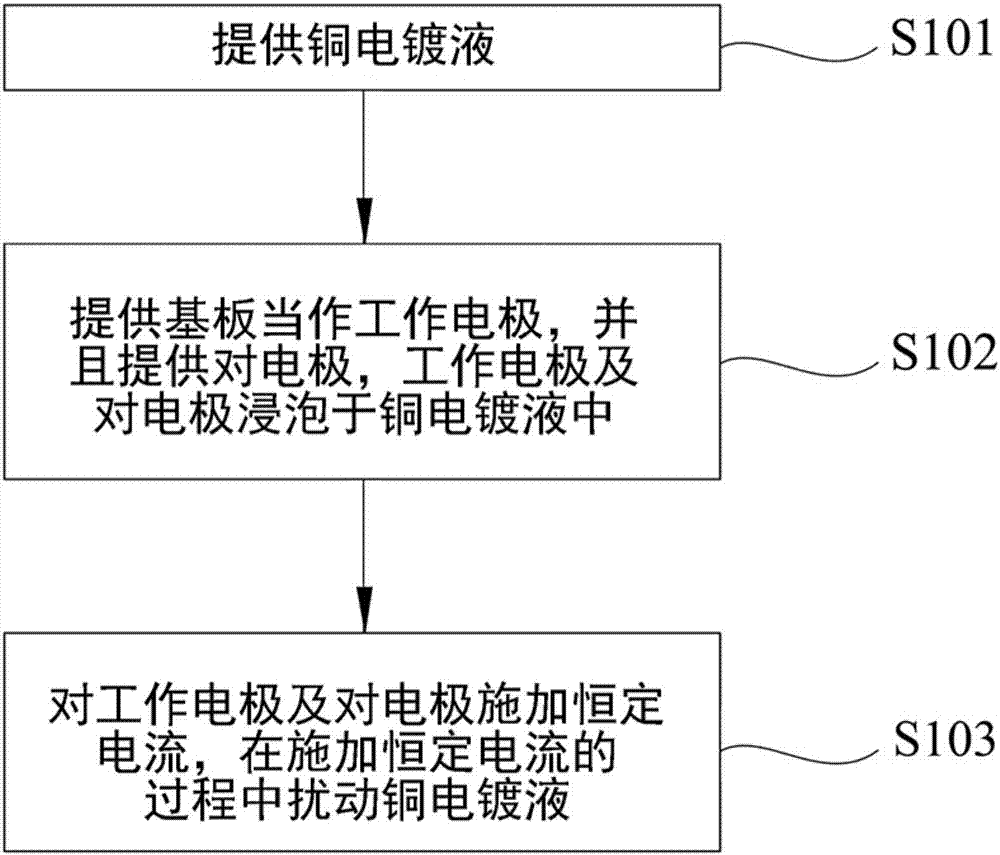

[0064] to accompany figure 1 And provide copper electroplating solution with reference to the concentration in Table 1 (sorted out at the end of the specification), and place the prepared copper electroplating solution in the electroplating tank of the electroplating equipment (step S101). Copper electroplating baths consist of the following concentrations of substances:

[0065] 1.2×10 5 ppmCuSO 4 ·5H 2 O;

[0066] 1.176×10 5 ppm of H 2 SO 4 ;

[0067] 60ppm Cl - ;

[0068] 6ppm SPS;

[0069] PEG 20000 at 240ppm; and

[0070] JGB, so that the concentration ratio of JGB:PEG 20000 is 1:40000.

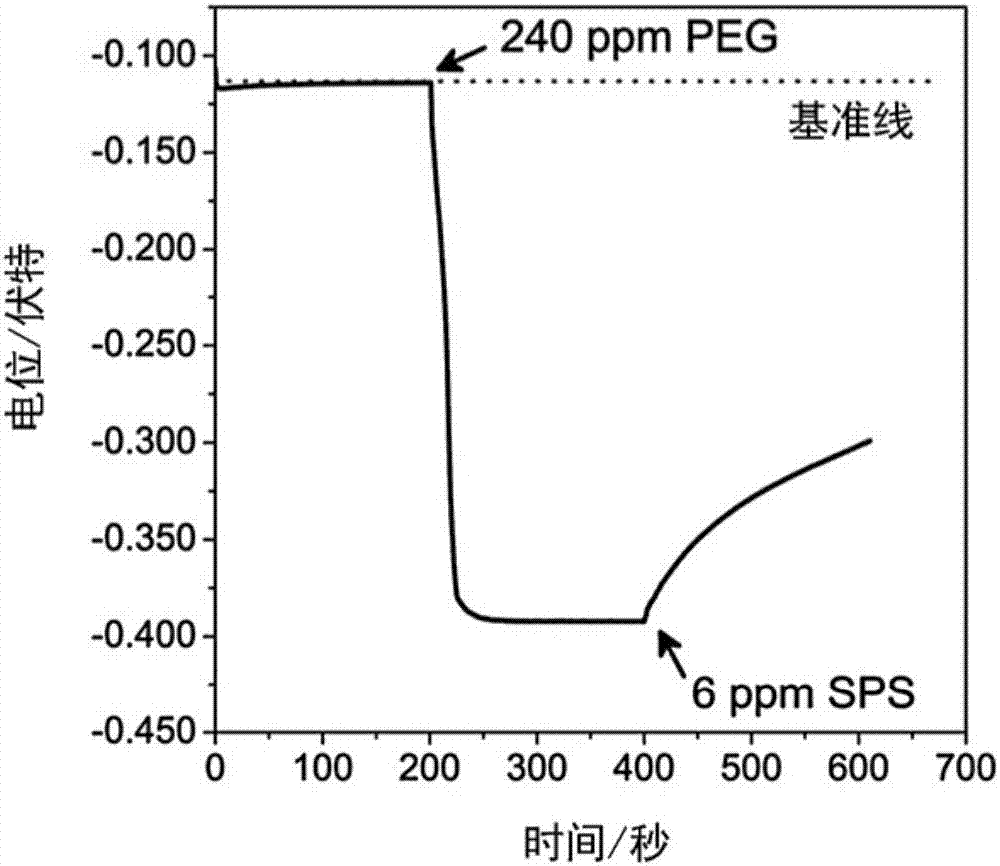

[0071] In order to observe the effect of SPS and PEG on the plating potential during the following electroplating, so as to understand their roles in electroplating. Therefore, in this example, PEG 20000 and SPS were added sequentially when the current was applied. In other embodiments, SPS and PEG 20000 have been added to the copper electroplating solution before electropl...

Embodiment 2-16

[0077] Electroplating was performed in the same manner as in Example 1, the difference being that the added concentrations of SPS and PEG 20000 are shown in Table 1. After the electroplating is completed, the observation results on the surface of the copper film layer are also presented in the Figure 4 , Figure 5 middle.

Embodiment 17

[0079] Electroplating was performed in the same manner as in Example 1, except that the concentrations of SPS and PEG 20000, and the current density are shown in Table 1. After the electroplating is completed, the observation results on the surface of the copper film layer show Figure 6 , Figure 7 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com