Module type heat exchanger utilizing suspension and special sealing structure and assembly method

A sealed structure, modular technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of different thermal expansion coefficient, heating surface falling off, difficult sealing, etc., to avoid thermal expansion cracking problems, improved safety and tightness, improved maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] In order to facilitate the understanding of those skilled in the art, the present invention will be further described with reference to the accompanying drawings.

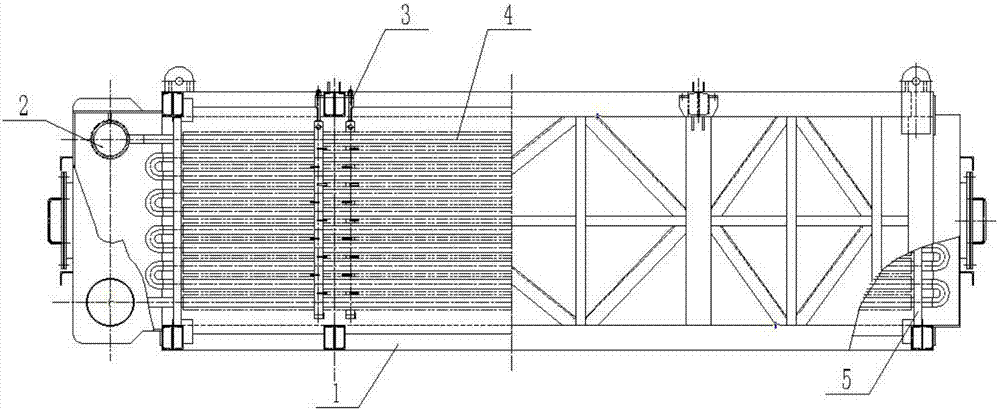

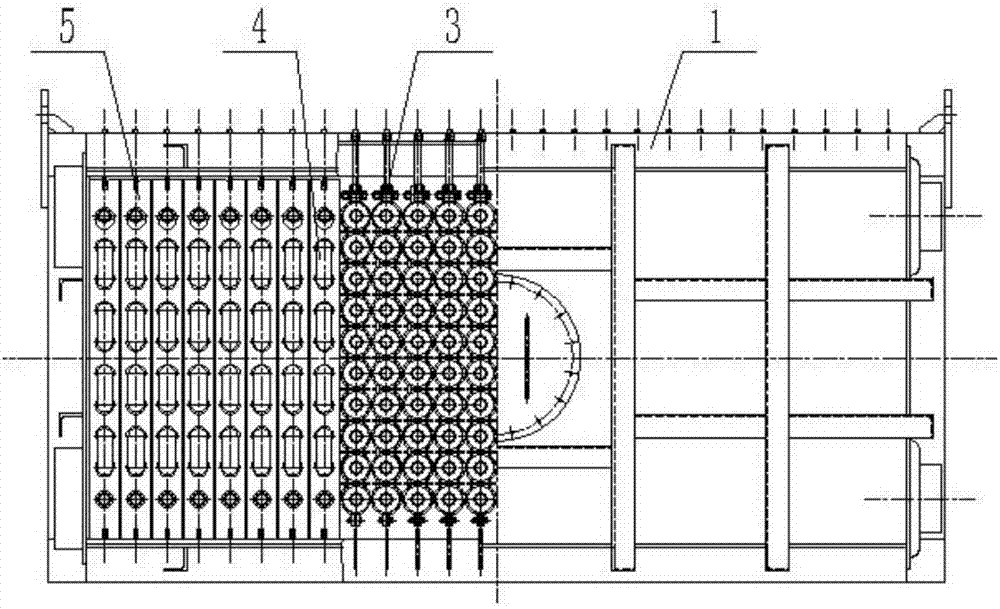

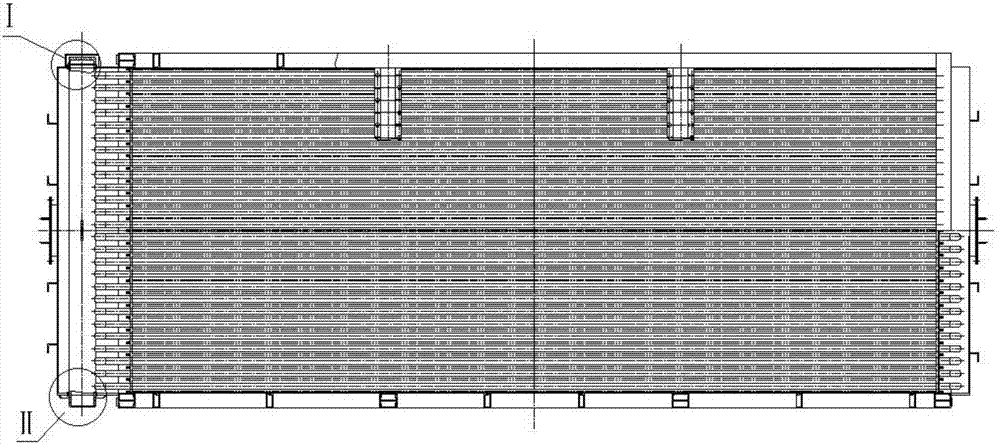

[0047] Such as Figure 1 to Figure 3 As shown, a modular heat exchanger using a hanging and a special sealing structure includes a shell 1. A number of lifting lugs 12 are provided on the top of the shell 1. The shell 1 includes a frame welded by beams. The length deviation of the diagonal line shall not be greater than 7mm, and the joints of the section steel constituting the beam shall be welded firmly, such as Picture 10 As shown, a number of heat exchange tube groups 4 are arranged inside the shell 1, one end of the heat exchange tube group 4 is provided with a header device 2, the heat exchange tube group 4 is provided with a hanging device 3 for hanging, and both ends of the heat exchange tube group 4 With support plate 5 support, such as Figure 15 to Figure 17 As shown, the supporting plate 5 of the pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap