A kind of alkylation catalyst for generating p-methylethylbenzene and preparation method thereof

A p-methylethylbenzene and catalyst technology, which is applied in the field of alkylation catalysts for generating p-methylethylbenzene and its preparation, can solve unsatisfactory problems and achieve excellent reactivity, important application value, and high PET selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

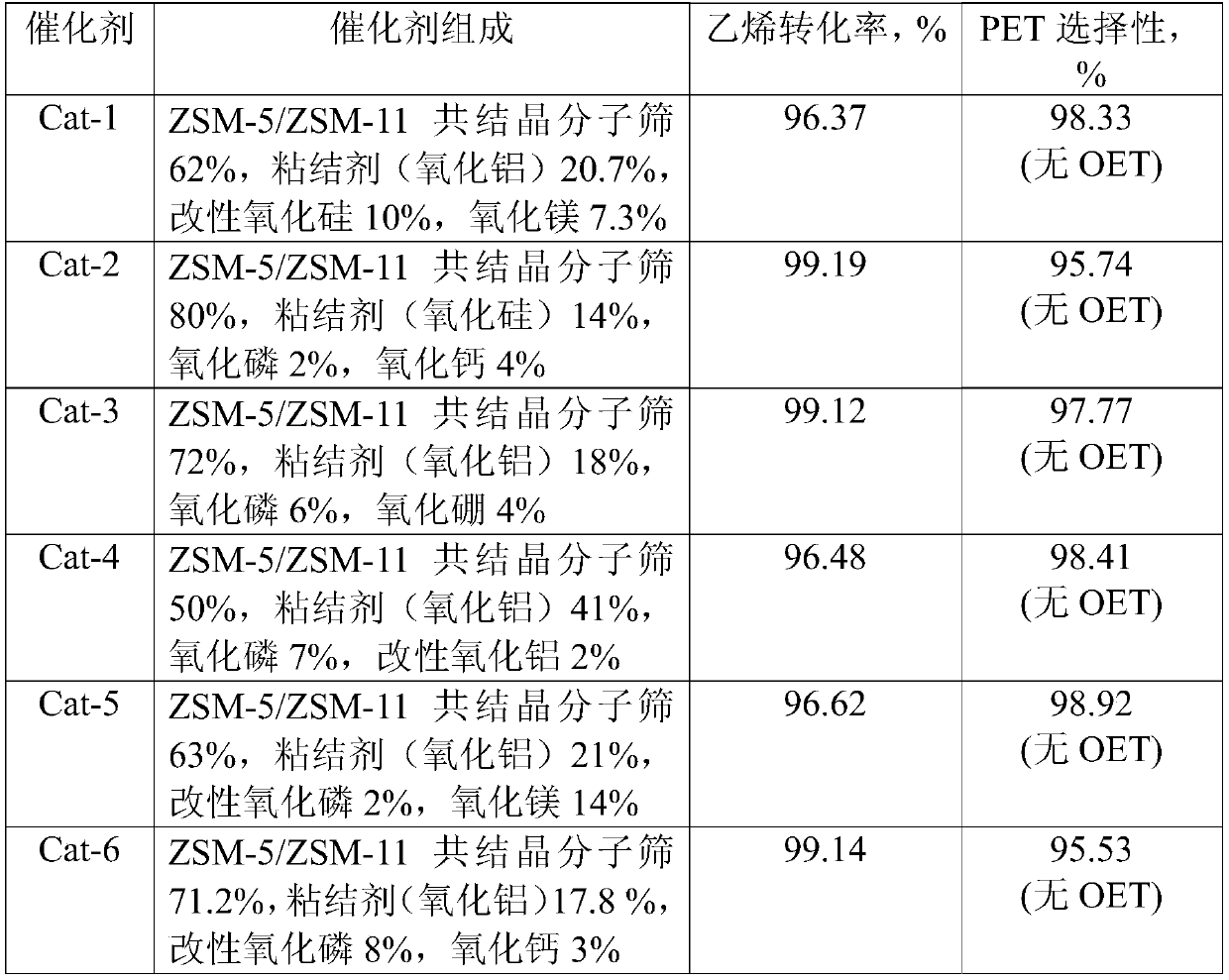

Examples

Embodiment 1

[0019] Get the ZSM-5 / ZSM-11 co-crystal molecular sieve that contains 80% ZSM-5 of 150g, adopt the dilute hydrochloric acid solution of 0.3M to carry out acid treatment to it twice, solid-liquid ratio 1 / 5 (g / ml), acid treatment temperature at 75°C for 2 hours, wash the acid-treated solid product until the washing liquid is neutral, and dry at 120°C for 8 hours to obtain solid powder a1; take 100g of solid powder a1 and 41.4g of alumina, the dry basis mass percentage of the two 75%: 25%, after adding 3.5g of Selina powder (accounting for 3% of the total mass on dry basis) and mixing, then adding 70g of dilute nitric acid solution with a mass concentration of 10% (total mass ratio on dry basis is 0.6:1) to carry out Kneading and extruding into strips, drying at 110°C for 8 hours, and calcining at 540°C for 6 hours to obtain a molded product b1; impregnating b1 with cyclohexane solution of ethyl orthosilicate, drying at 100°C for 10 hours, and calcining at 530°C for 3 hours. The m...

Embodiment 2

[0021] Get the ZSM-5 / ZSM-11 co-crystal molecular sieve that contains 50%ZSM-5 of 150g, adopt the dilute nitric acid solution of 0.1M to carry out acid treatment to it twice, solid-liquid ratio 1 / 10 (g / ml), acid treatment temperature at 60°C for 3 hours, wash the acid-treated solid product until the washing liquid is neutral, and dry at 100°C for 20 hours to obtain solid powder a2; take 100g of solid powder a2 and 39g of silica sol, and the mass percentage of the two on a dry basis is 85%: 15%, after adding 4.2g of turnip powder (accounting for 4% of dry basis total mass) and mixing, then adding 42g mass concentration is 15% dilute nitric acid solution (0.4:1 with dry basis total mass ratio) for kneading , extruded, then dried at 100°C for 15 hours and roasted at 530°C for 8 hours to obtain the molded product b2; b2 was impregnated with dilute phosphoric acid solution, dried at 120°C for 4 hours, and roasted at 500°C for 6 hours to obtain a molded product containing modified pho...

Embodiment 3

[0023] Get 150g ZSM-5 / ZSM-11 co-crystal molecular sieves containing 70% ZSM-5, adopt 0.2M dilute hydrochloric acid solution to carry out acid treatment twice to it, solid-liquid ratio 1 / 7 (g / ml), acid treatment temperature at 80°C for 2 hours, wash the acid-treated solid product until the washing liquid is neutral, and dry at 110°C for 12 hours to obtain solid powder a3; take 100g of solid powder a3 and 29.4g of alumina, the dry basis mass percentage of the two It is 80%:20%, after adding 3.2g squash powder (accounting for 3% of dry basis total mass) and mixing, then adding 85g mass concentration is 8% dilute nitric acid solution (with dry basis total mass ratio is 0.8:1) to carry out Kneading and extruding into strips, drying at 110°C for 8 hours, and roasting at 540°C for 5 hours to obtain the molded product b3; impregnating b3 with ammonium hydrogen phosphate solution, drying at 110°C for 6 hours, and roasting at 520°C for 4 hours to obtain the modified phosphorus oxide C3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com