Method for realizing first twist difference of multiple strands on two-for-one twister

A two-for-one twister and differentiated technology, which is applied in the field of realizing the differentiation of multi-strand yarn primary twist, can solve the problems that cannot be realized, and achieve the effects of improving production efficiency, simplifying the twisting process, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

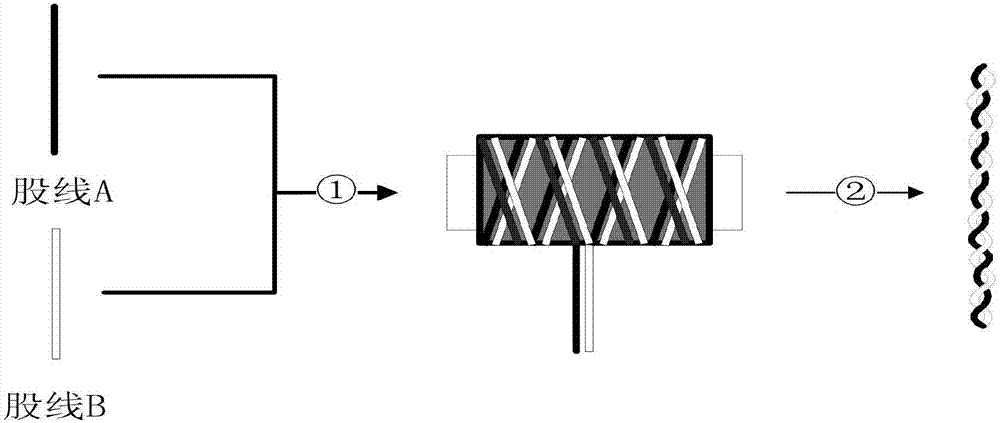

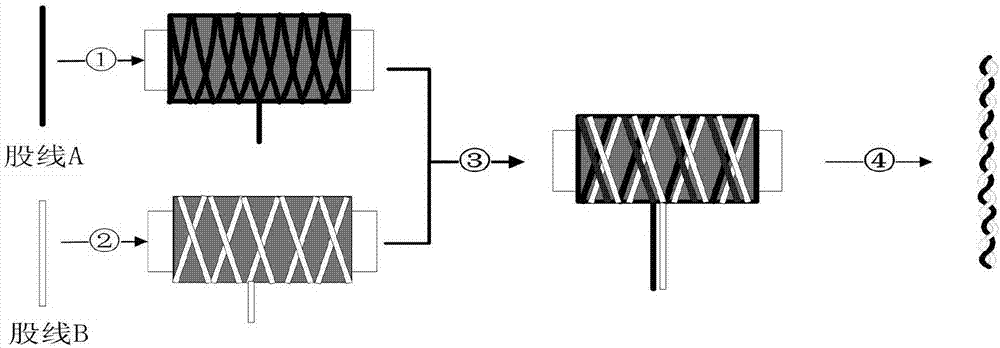

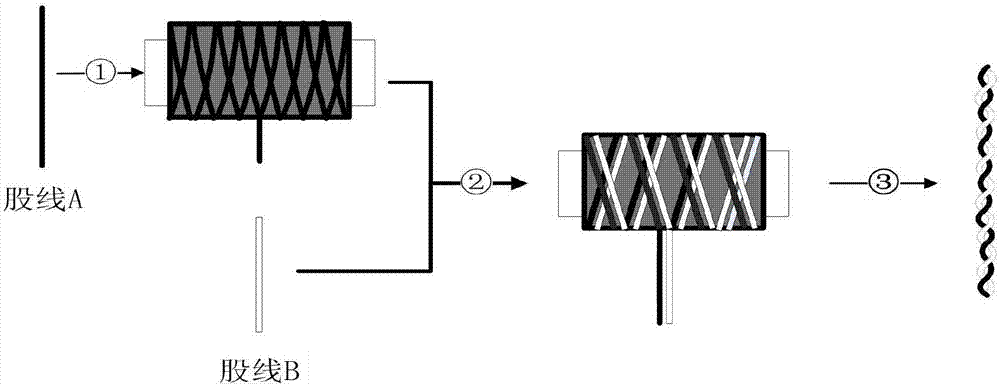

[0022] Example 1, such as image 3 Shown, the present invention is to realize the primary twist differentiation of multi-strand twisted yarn on the two-for-one twisting machine with high production efficiency, according to the primary twist difference of each strand in the multi-strand twisted yarn, the strands with difference in primary twist The twist is applied separately, referred to as pre-twisting, to balance the difference in the initial twist between it and other strands, and then use the general twisting technology of the two-for-one twister to perform twisting.

[0023] A method for realizing differential primary twist of multi-strand yarns on a two-for-one twister, the method is: at least two strands, adopting pretwist in the same direction for strands with large initial twist, and balancing the difference in primary twist with stepwise primary twist; For strands with small initial twist, reverse twist and pretwist are used to balance the difference in twist.

[00...

Embodiment 2

[0028] Embodiment 2, the difference between this embodiment and Embodiment 1 is that this embodiment includes A strands, B strands and C strands, wherein the twist of A strands is a, and the primary twist of B strands and C strands For b, assuming a>b, the twisting method is as follows:

[0029] (1) Add primary twist a-b to strand A to balance twist difference;

[0030] (2) Add initial twist b to A, B, C fibers at the same time, and ply;

[0031] (3) Use the two-for-one twister for double twisting, so as to realize the difference in the initial twist.

[0032] Beneficial effects of the present invention: the twisting of multi-strand twisted yarns with differentiated initial twists on the two-for-one twisting machine simplifies the twisting process, improves production efficiency, and is beneficial to quality improvement and loss reduce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com