Production process of basalt filter material

A technology of filter material and production process, applied in the field of production process of basalt filter material, can solve the problems of reducing the service life of equipment, easy blockage, incomplete filtration, etc., and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

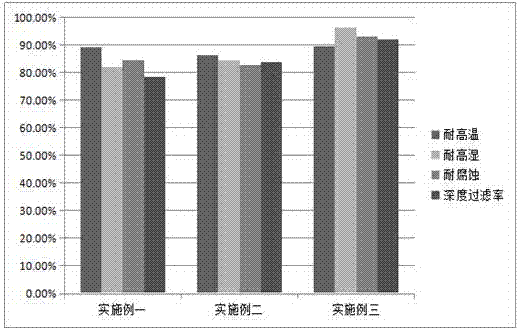

Examples

Embodiment 1

[0024] A production process of basalt filter material, comprising the steps of:

[0025] S1. Component raw material preparation: 10 parts of basalt fiber, 3 parts of mixed resin, 15 parts of film-forming agent, 15 parts of carbon fiber tube, 4 parts of synthetic fiber, 8 parts of inorganic phosphate flame retardant, 3 parts of reinforcing agent and 3 parts of curing agent share;

[0026] S2. Wash 10 parts of basalt fiber with water, filter to remove impurities, put it in a desiccator at a temperature of 135°C for 60 minutes, dry it, and then store it in a sealed container;

[0027] S3. Heat 15 parts of the film-forming agent to 60°C, stir to form a sol, and let it cool for 15 minutes before use;

[0028] S4. Add 15 parts of the film-forming agent to be used in S3 to 10 parts of the basalt fiber preserved in S2, put it into a stirrer at a speed of 120 rpm, and stir evenly for 30 minutes to form a mixture A;

[0029] S5. Put 3 parts of mixed resin into a container, add 3 parts...

Embodiment 2

[0034] A production process of basalt filter material, comprising the steps of:

[0035] S1. Component raw material preparation: 11 parts of basalt fiber, 5 parts of mixed resin, 18 parts of film-forming agent, 20 parts of carbon fiber tube, 6 parts of synthetic fiber, 9 parts of inorganic phosphate flame retardant, 6 parts of reinforcing agent and 4 parts of curing agent share;

[0036] S2. Wash 11 parts of basalt fibers with water, filter to remove impurities, put them in a desiccator at a temperature of 155°C for 90 minutes, dry them, and then store them in a sealed container;

[0037] S3. Heat 18 parts of the film-forming agent to 70°C, stir to form a sol, let it cool for 18 minutes, and set aside;

[0038] S4. Add 16 parts of the film-forming agent to be used in S3 to 11 parts of the basalt fiber preserved in S2, put it into a stirrer, the rotating speed is 130 rpm, and the time is 60 minutes, and stir evenly to form a mixture A;

[0039] S5. Put 6 parts of mixed resin ...

Embodiment 3

[0044] A production process of basalt filter material, comprising the steps of:

[0045] S1. Component raw material preparation: 12 parts of basalt fiber, 8 parts of mixed resin, 20 parts of film-forming agent, 25 parts of carbon fiber tube, 12 parts of synthetic fiber, 15 parts of inorganic phosphate flame retardant, 8 parts of reinforcing agent and 6 parts of curing agent share;

[0046] S2. Wash 112 parts of basalt fibers with water, filter to remove impurities, put them in a desiccator at a temperature of 175° C. for 120 minutes, dry them, and then store them in a sealed container;

[0047] S3. Heat 20 parts of the film-forming agent to 90°C, stir to form a sol, let it cool for 20 minutes, and set aside;

[0048] S4. Add 20 parts of the film-forming agent to be used in S3 to 12 parts of the basalt fiber preserved in S2, put it into a stirrer, the rotating speed is 135 rpm, and the time is 90 minutes, and stir evenly to form a mixture A;

[0049] S5. Put 8 parts of mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com