Improved lift/collison detection

A technology of collision detection and robotics, applied in control/adjustment systems, vehicle position/route/height control, non-electric variable control, etc., can solve problems such as injury or damage, and achieve the effect of reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The disclosed embodiments will now be described more fully with reference to the accompanying drawings, which illustrate some embodiments of the invention. This invention may, however, be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided by way of example so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to the art. technical staff. Like reference numerals refer to like elements throughout.

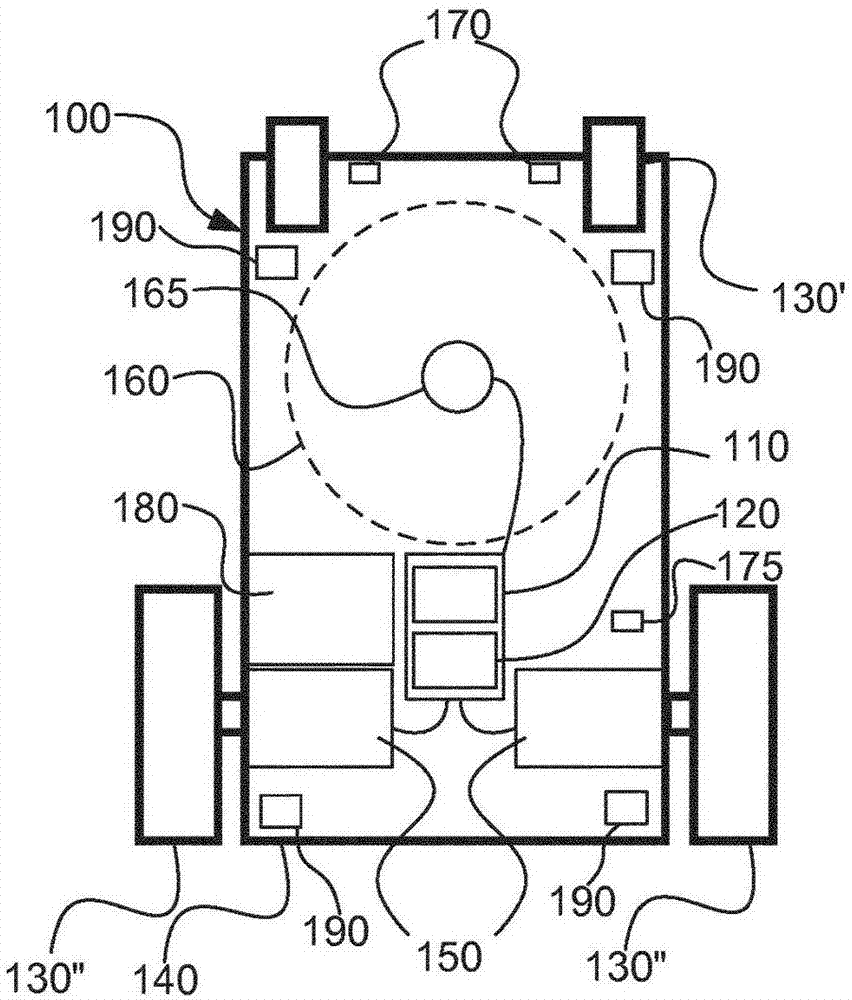

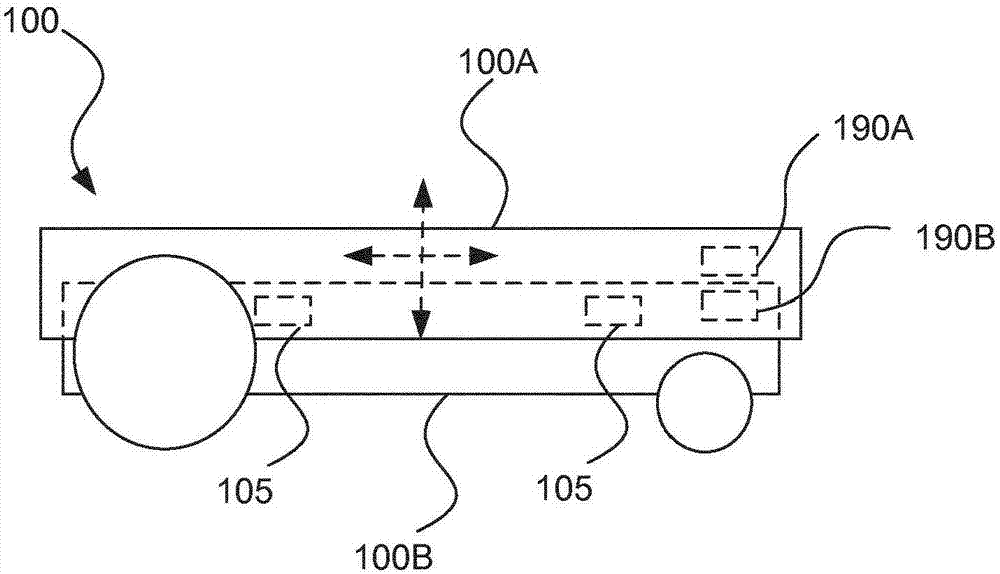

[0028] figure 1 A schematic overview of a robotic work tool 100 having a body 140 and a plurality of wheels 130 is shown. exist figure 1 In the exemplary embodiment, the robotic work tool 100 has four wheels 130 , two front wheels 130 ′ and two rear wheels 130 ″. At least some of the wheels 130 are drivably connected to at least one electric motor 150 . It should be noted that even though the description herein focuses on an ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap