High-volume centrifugal cup

A centrifugal cup and large-capacity technology, applied in centrifuges and other directions, can solve the problems of centrifugal cup deformation, insufficient strength, unfavorable results, etc., and achieve the effect of increasing thickness, increasing strength, and increasing the number of separations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example

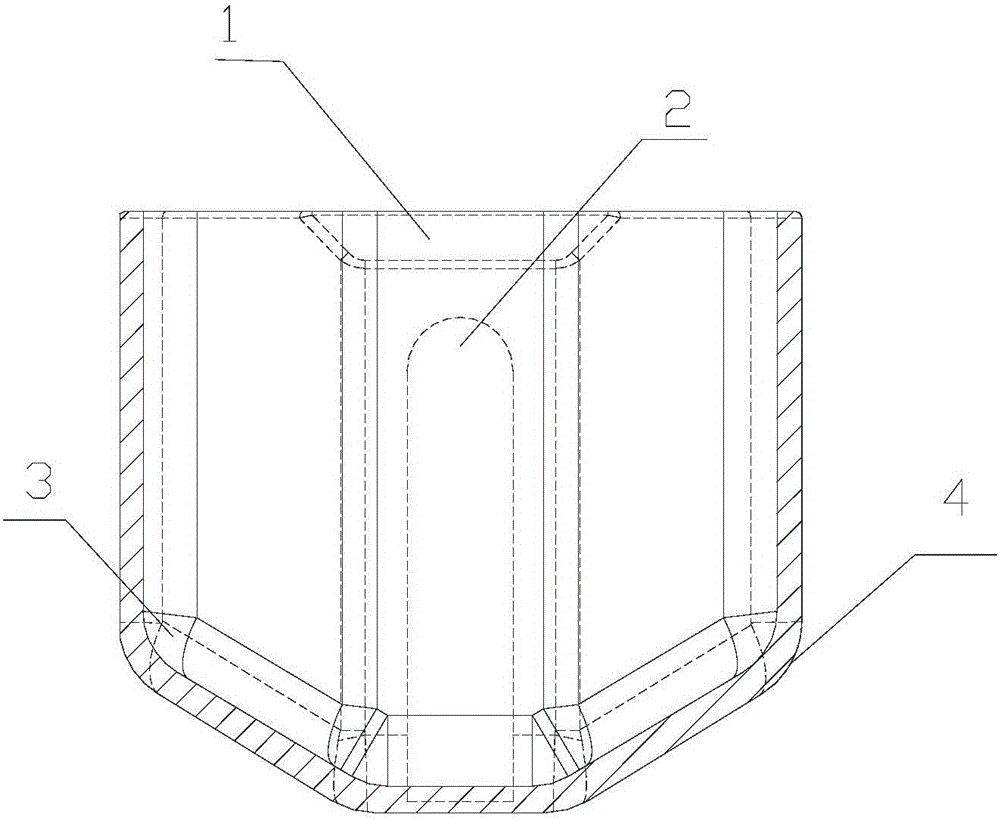

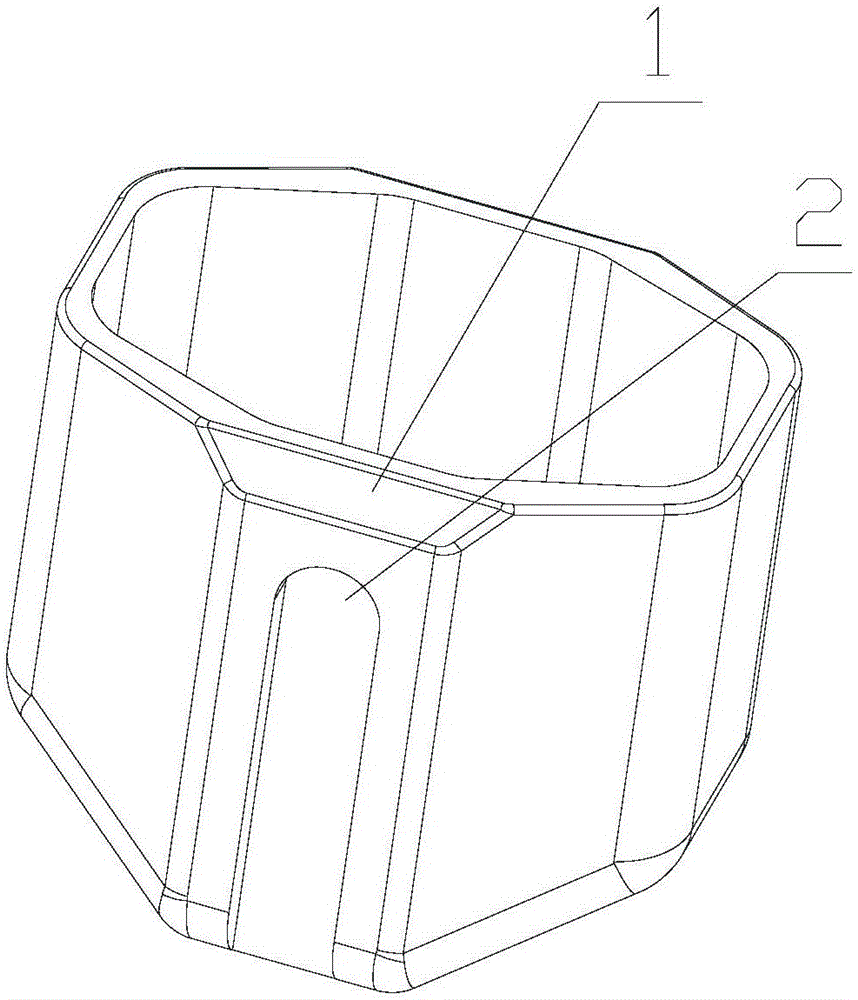

[0022] A kind of large-capacity centrifugal cup, its structure is as Figure 1-2 As shown, there are pin hangers 1 and hook grooves 2 in the middle of the front and back surfaces, the two sides are vertical structures, and the bottom is a symmetrical inclined structure, forming an angle of 30-32° with the horizontal direction. The depth gradually increases from the sides to the middle. In this embodiment, the angle between the bottom and the horizontal direction is 31°. The design of the included angle, on the one hand, is convenient to use in the centrifuge, and more importantly, during use, the product placed inside will not be thrown out of the centrifuge cup due to excessive centrifugal force, and because the depth changes gradually and a specific centrifuge is selected The inclination angle makes the centrifugal effect of the product reach the best.

[0023] The side and bottom of the centrifugal cup are excessively connected in an arc shape, wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap