Production method of inorganic fiber roof heat-insulation waterproofing system

A technology of inorganic fiber and production method, which is applied in the direction of roof cladding and building roof, etc., can solve the problems of flame-retardant and fire-resistant performance defects, poor heat preservation effect, self-heavy and unfavorable building load bearing, etc., achieve good heat insulation and sound insulation effect, and save process and man-hours, the effect of saving manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

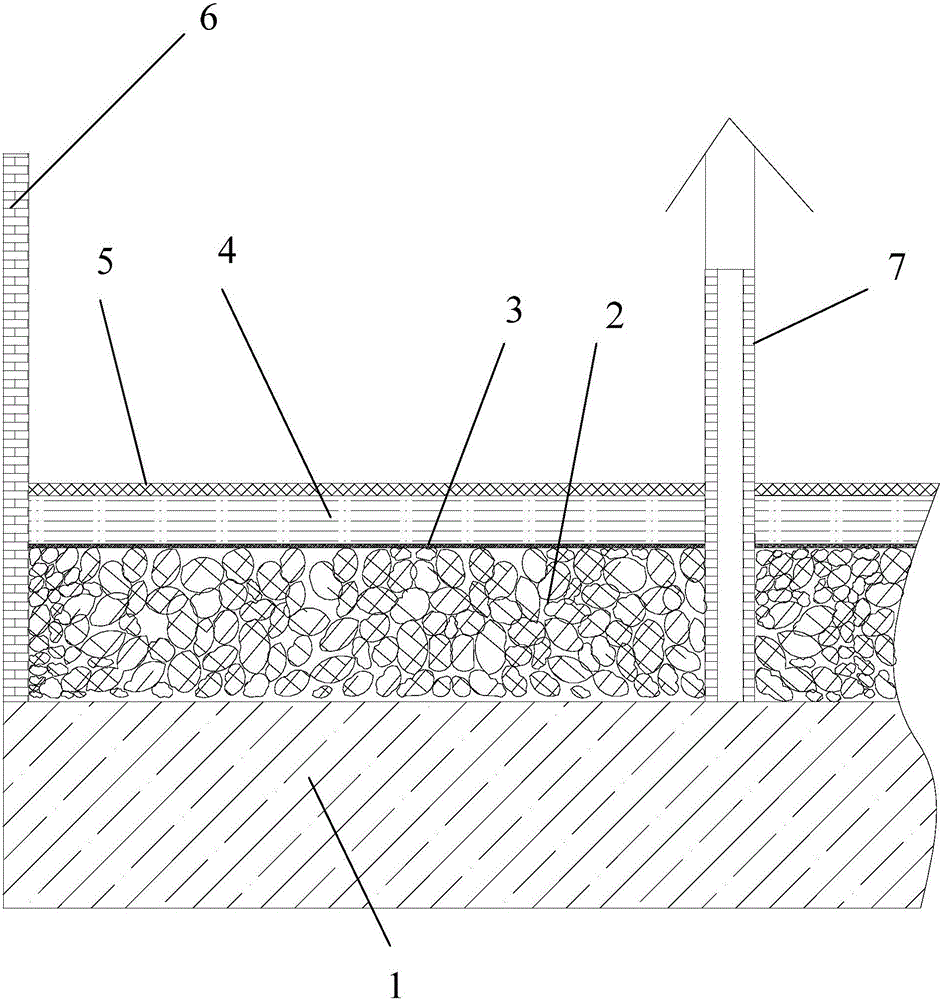

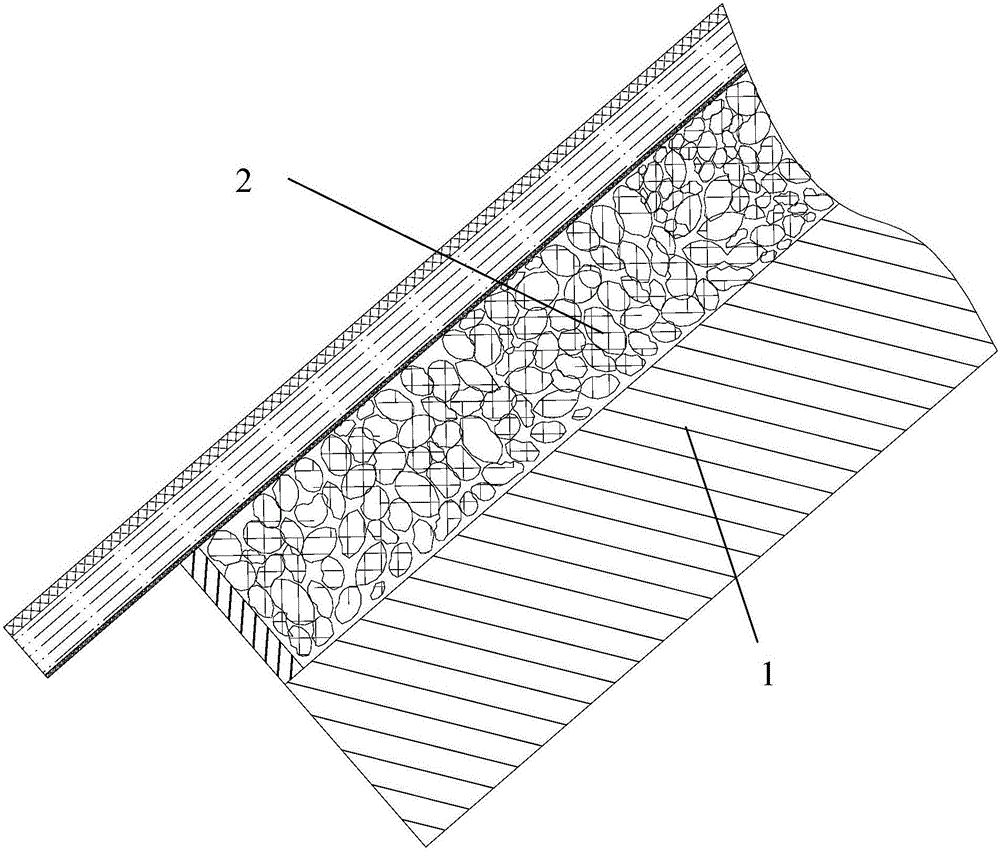

[0026] figure 1 It is a schematic diagram of the inorganic fiber roof insulation and waterproof system, such as figure 1 As shown, the upper surface of the horizontal roof 1 is sequentially laid with inorganic fiber layer 2, non-woven fabric 3, waterproof layer 4 and waterproof coating 5 from bottom to top, and a parapet 6 is also arranged on the horizontal roof 1 according to the construction requirements. and flue7. When making a roof insulation and waterproof system, the above-mentioned ones need to be laid on the top of the roof in sequence. The main steps are as follows:

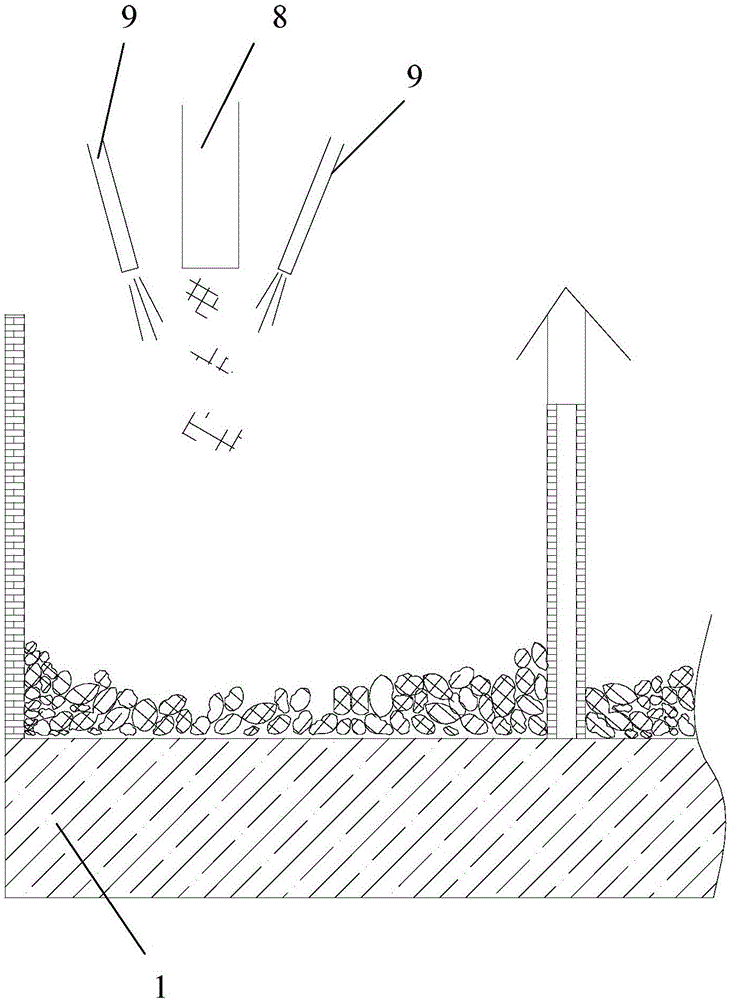

[0027] First, the inorganic fiber and the binder are sprayed synchronously to evenly cover the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filling density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com