Method and device for preparing aromatic hydrocarbons and olefins by catalytic hydrogenation coupled catalytic cracking of bio-oil

A catalytic cracking and catalytic hydrogenation technology, applied in the fields of hydrotreating process, hydrocarbon oil treatment, ethylene production, etc., can solve the problems of loss of catalytic performance, reduction of process stability and continuity, easy coking of catalyst, etc., and achieve process cost Low, high liquid yield, easy to condense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described below with reference to the accompanying drawings.

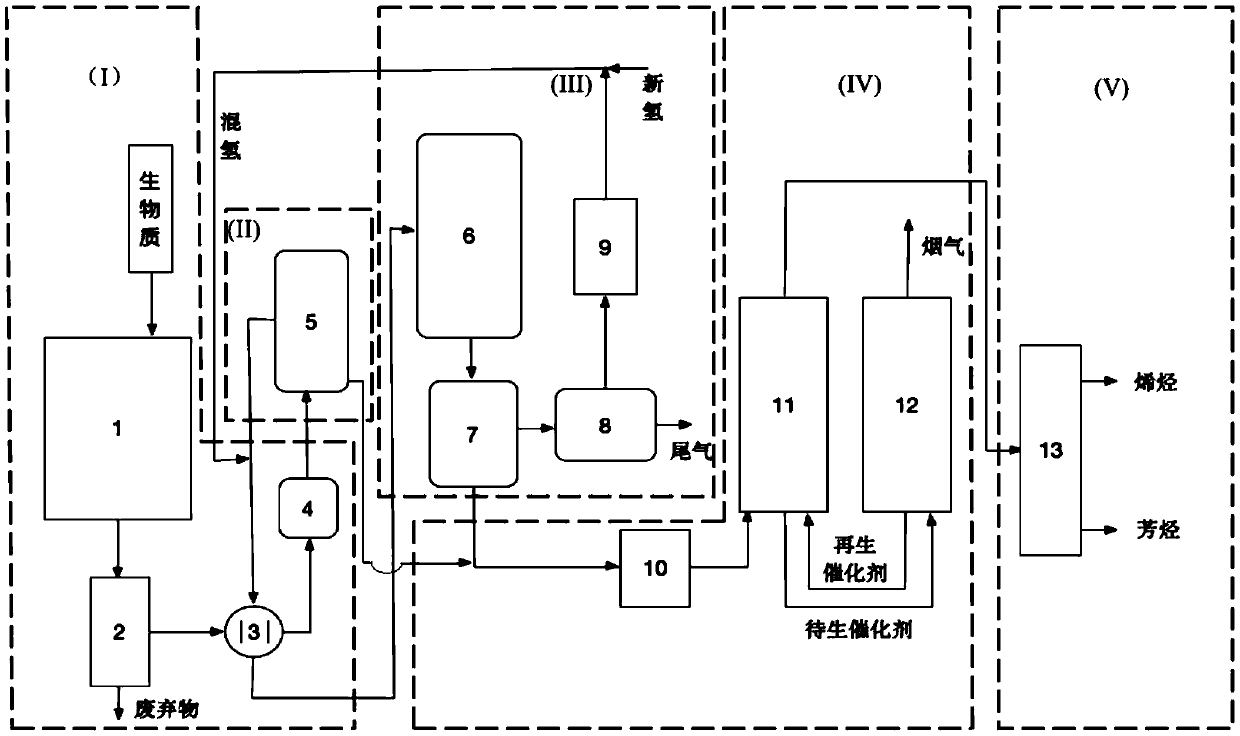

[0042] The invention provides a device for preparing aromatic hydrocarbons and olefins by using catalytic hydrogenation coupled catalytic cracking of bio-oil; Hydrogen system (III), catalytic cracking system (IV) and separation and purification system (V), in thermal cracking unit (1), cyclone separator (2), heat exchanger (3), flash condenser (4), static Separator (5), fixed bed catalytic hydrogenation reactor (6), gas-liquid separator (7), circulating gas treatment device (8), circulating hydrogen compressor (9), heating furnace (10), catalytic cracking Realize on a complete set of devices such as reactor (11), catalyst regenerator (12) and rectifying tower (13).

[0043] Through the low-temperature and low-pressure catalytic hydrogenation upgrading of the light oil phase and the co-catalytic cracking of the heavy oil phase, it solves the problem that the catalyst is easily c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com