Method for treating grease through granular activated carbon in reproducible mode and system thereof

A granular carbon and grease technology, applied to the system field used in the above method, can solve the problems of large consumption, material loss, environmental pollution, etc., and achieve the effect of reducing operating costs and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

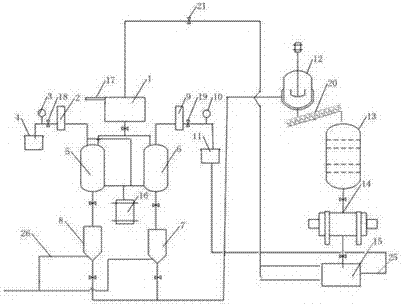

[0056] A system for treating grease with granular carbon in a renewable manner, the system includes a crude oil tank 16, and the crude oil tank 16 is divided into two branch pipelines, which are respectively connected to the lower parts of the adsorption tower I5 and the adsorption tower II6;

[0057] The adsorption tower I5 and the adsorption tower II6 are connected by pipelines;

[0058] The outlets of adsorption tower Ⅰ5 and adsorption tower Ⅱ6 are respectively connected with washing tank Ⅰ8 and washing tank Ⅱ7, and the pipes at the outlets of washing tank Ⅰ8 and washing tank Ⅱ7 are connected to the carbon feeding tank 12, and there is a dehydration screw under the carbon feeding tank 12 Conveyor 20, the discharge part of dehydration screw conveyor 20 is facing the inlet of multi-stage regeneration furnace 13; Tank 1 is connected;

[0059] The lower part of the high-level carbon tank 1 is divided into two pipelines, which lead to the adsorption tower I5 and the adsorption ...

Embodiment 2

[0098] The structure is substantially the same as that of Example 1, the difference is that there is no connected pipeline between the adsorption tower I5 and the adsorption tower II6; that is, the oil to be decolorized can only be selected from the adsorption tower I5 or the adsorption tower II6, or the adsorption tower I5 and the adsorption tower II6. Tower Ⅱ6 decolorizes oil at the same time, and cannot be decolorized twice.

[0099] The oil to be decolorized in the crude oil tank 16 enters the adsorption tower I5 and the adsorption tower II6 respectively, and undergoes decolorization treatment; the rest of the process is the same as that of Example 1.

Embodiment 3

[0101] The structure is substantially the same as that of Example 1, the difference is that there is no connected pipeline between the crude oil tank 16 and the adsorption tower II6; that is, the oil to be decolorized can only be decolorized by the adsorption tower I5 first, and then passed through the adsorption tower II6. Secondary decolorization treatment of oil; or the case of decolorization treatment only by adsorption tower I5.

[0102] The above data prove that the system of the present invention is applied to the decolorization of oils and fats, and its decolorization effect is good, and because most of the granular carbon is recycled and reused in the decolorization process, the cost is saved, and it is a kind of decolorization in the whole decolorization field. Great progress.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com