Soluble elemental sulfur/terpene copolymer with higher molecular weight and its preparation method and application

A technology of elemental sulfur and copolymer, applied in the field of soluble elemental sulfur/terpene copolymer and its preparation, can solve problems such as application limitation and low molecular weight, and achieve the effects of avoiding waste, high reaction yield and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of elemental sulfur / terpene copolymer, comprising the steps of:

[0041] (1) Add 28g of sublimated sulfur and tetramethyl disulfide to a 150ml four-neck flask equipped with a mechanical stirrer, a condenser, and a thermometer inserted, and heat under nitrogen atmosphere until the sulfur is completely melted, then add 10g of pinene, and heat at 700r / Min speed stirring for about 10min until uniform;

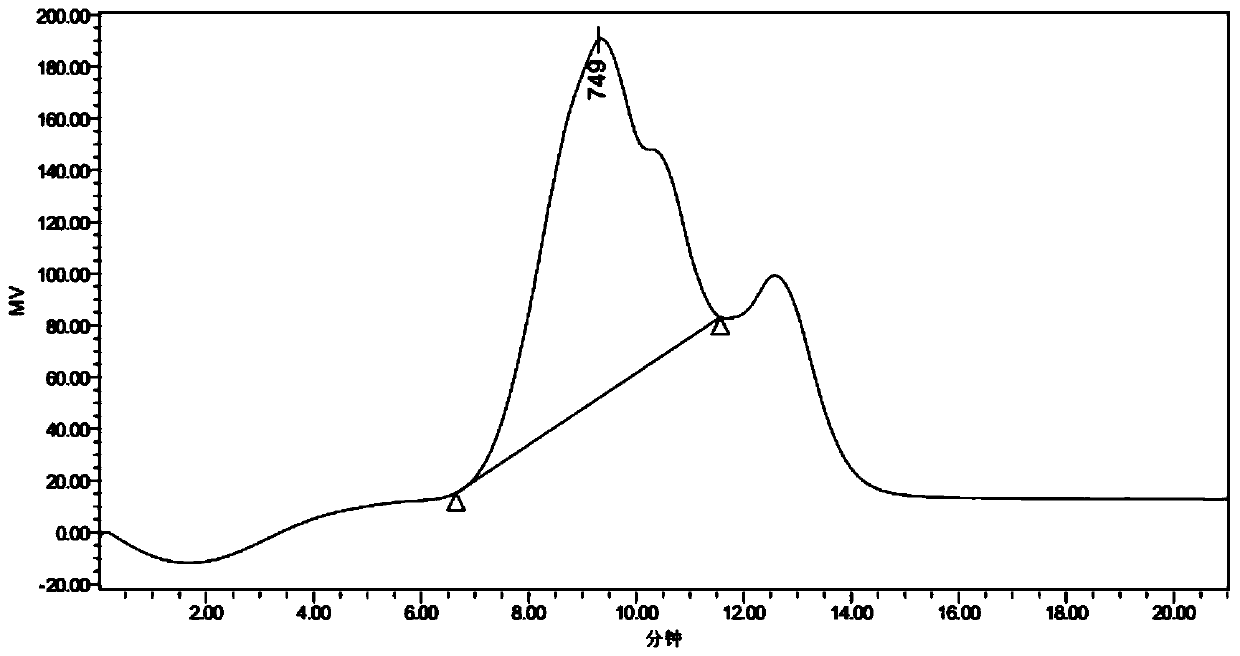

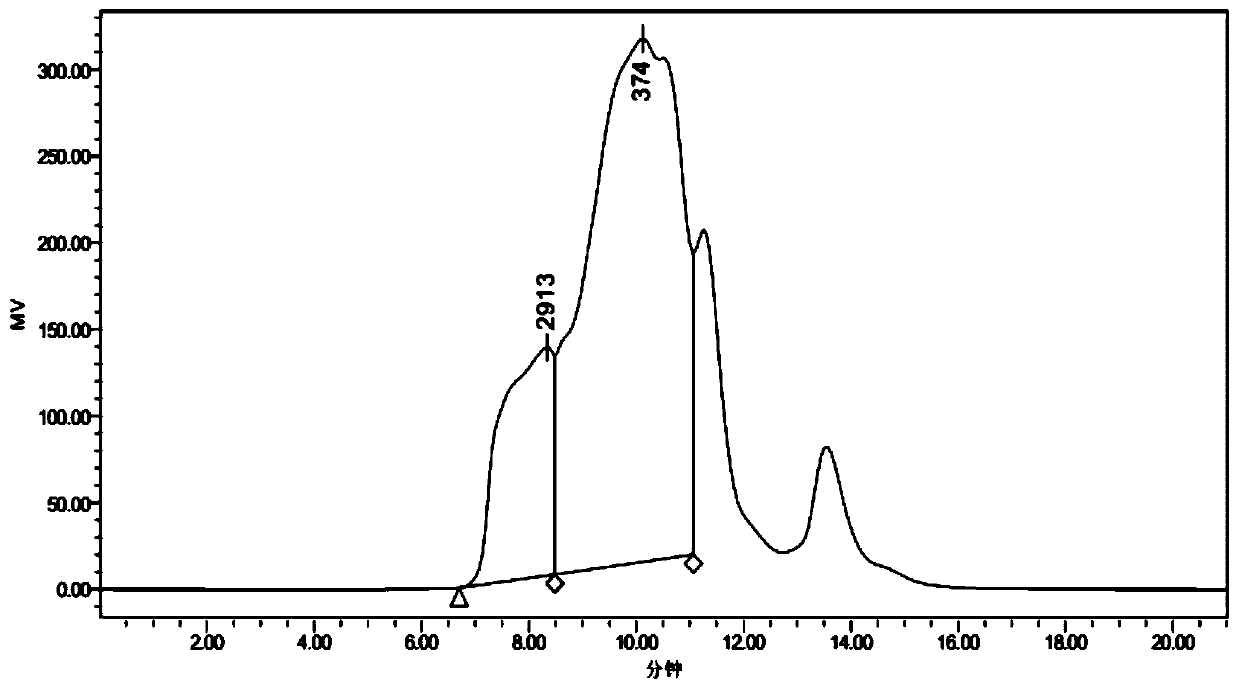

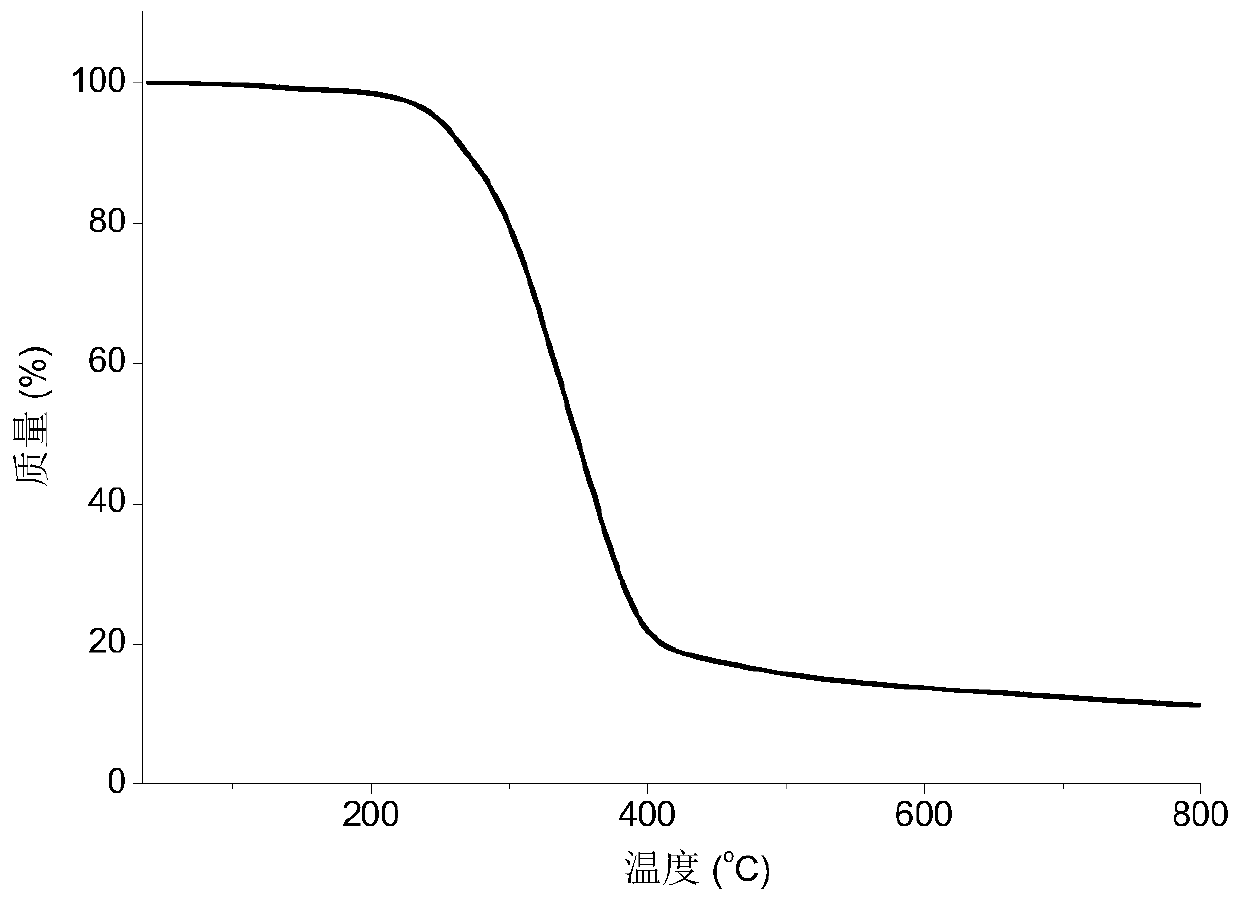

[0042] (2) Heat up the uniformly mixed reaction system in step (1) to 155°C to carry out polymerization reaction. After 2 hours, the product is distilled under reduced pressure for 20 minutes to remove unreacted monomers, and then rapidly cooled and solidified with liquid nitrogen to obtain a dark red block Solid polymerized sulfur crude product; the crude product is dissolved in tetrahydrofuran, filtered, and centrifuged to remove insoluble impurities; then the solvent is removed by rotary evaporation, and then placed in a vacuum drying oven at 40°C fo...

Embodiment 2

[0047] A preparation method of elemental sulfur / terpene copolymer, comprising the steps of:

[0048] ⑴Add 28g of sublimated sulfur and ammonium persulfate to a 150ml four-necked flask equipped with mechanical stirring, a condenser, and a thermometer inserted, and heat under nitrogen atmosphere until the sulfur is completely melted, then add 10g of pinene, and use 700r / min Stir at a speed of about 10 minutes until uniform;

[0049] (2) Heat up the uniformly mixed reaction system in step (1) to 155°C to carry out polymerization reaction. After 2 hours, the product is distilled under reduced pressure for 20 minutes to remove unreacted monomers, and then rapidly cooled and solidified with liquid nitrogen to obtain a dark red block Solid polymerized sulfur crude product; the crude product is dissolved in tetrahydrofuran, filtered, and centrifuged to remove insoluble impurities; then the solvent is removed by rotary evaporation, and then placed in a vacuum drying oven at 40°C for 12...

Embodiment 3

[0052] A preparation method of elemental sulfur / terpene copolymer, comprising the steps of:

[0053] (1) Add 28g of sublimated sulfur into a 150ml four-neck flask equipped with a mechanical stirrer, a condenser, and a thermometer inserted into it, add tetramethyl disulfide, heat under a nitrogen atmosphere until the sulfur is completely melted, add 14g of pinene, and heat at 700r / Min speed stirring for about 10min until uniform;

[0054] (2) Heat up the uniformly mixed reaction system in step (1) to 155°C to carry out polymerization reaction. After 2 hours, the product is distilled under reduced pressure for 20 minutes to remove unreacted monomers, and then rapidly cooled and solidified with liquid nitrogen to obtain a dark red block Solid polymerized sulfur crude product; the crude product is dissolved in tetrahydrofuran, filtered, and centrifuged to remove insoluble impurities; then the solvent is removed by rotary evaporation, and then placed in a vacuum drying oven at 40°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com