Processing technology of potato-containing rice flour

A processing technology, potato starch technology, applied in the field of potato rice flour processing technology, can solve the problems of poor stickiness of potato starch, low nutritional value, difficulty in forming rice flour, etc., to increase potato content, increase nutritional value, and improve nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047] The processing technology of the potato rice noodles includes the following steps:

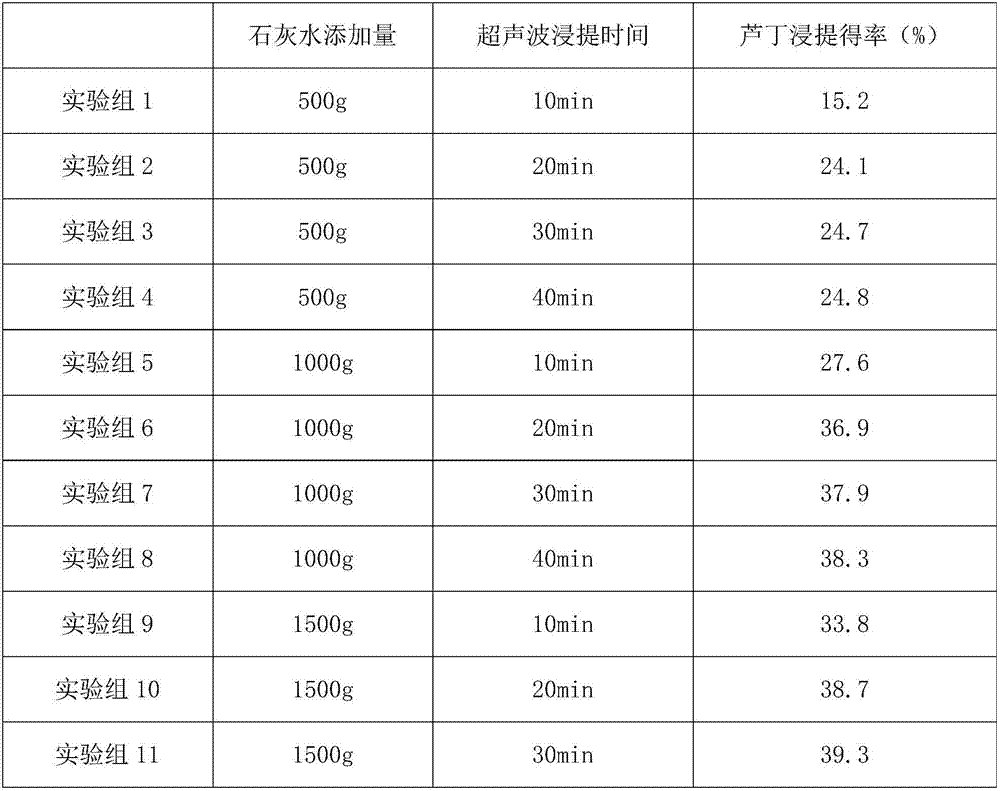

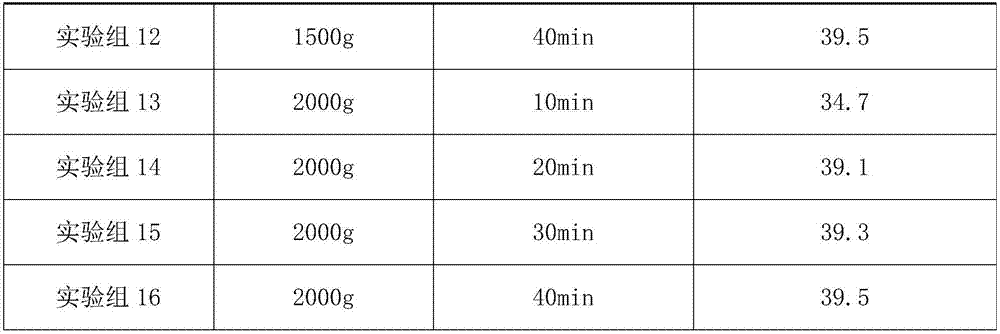

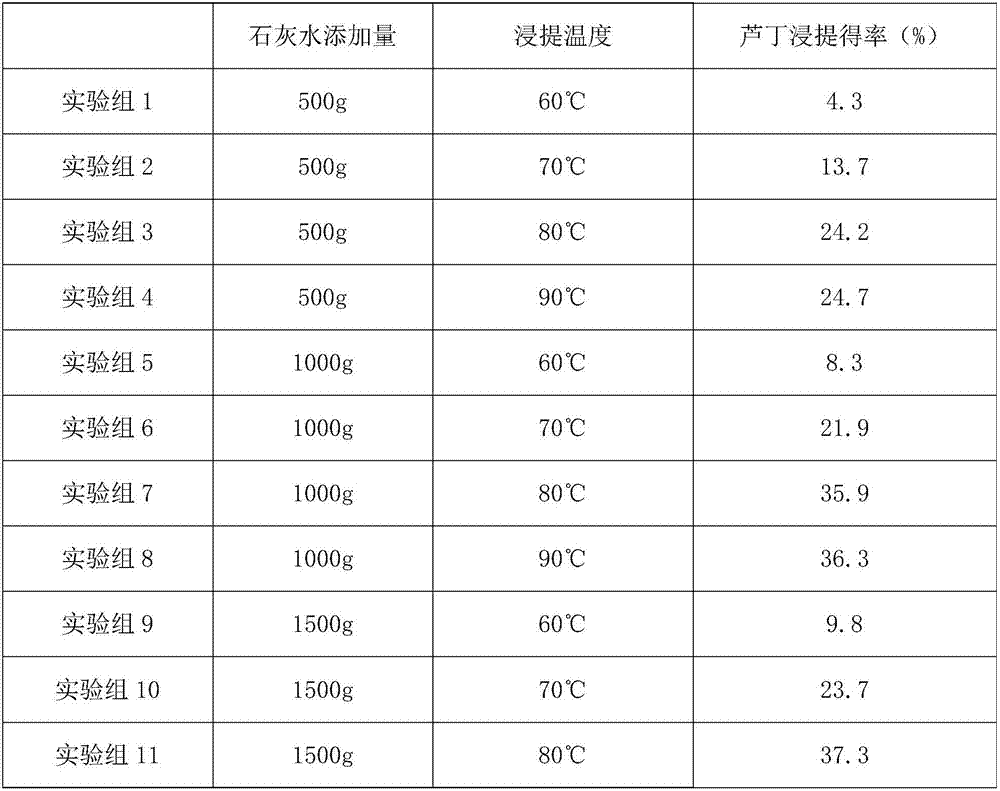

[0048] Step 1. Prepare a base material. The base material is a mixture of potato cooked powder, rutin powder, and rice flour. The weight ratio of each component is as follows: the content of potato cooked powder is 20%-35%, and the rutin powder 0-5%, the balance is rice flour, and the cooked potato flour is any one or a combination of whole potato flour and potato extruded powder;

[0049] Step 2: Prepare rice dough, add appropriate amount of additives to the base material prepared in Step 1, mix well, add water or potato liquid and stir to obtain rice dough;

[0050] Step 3: The rice dough obtained in Step 2 is made into rice noodles according to a conventional method.

[0051] The processing technology of the potato rice noodles of the present invention re-formulates the base material, that is, the cooked potato powder, rutin powder, and rice noodles are mixed in a certain proportion. The ric...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap