Automatic unwinding and winding device for maintenance tarpaulin of prefabricated component and using method of automatic unwinding and winding device

A technology of automatic retraction and prefabrication of components, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of high labor intensity, unsuitable fixed mold table, low efficiency, etc., and achieve the effect of reducing manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

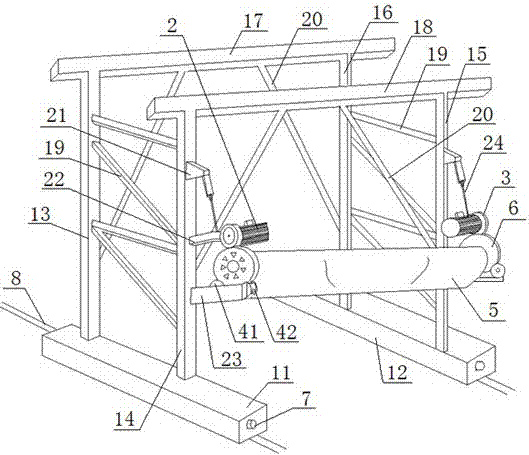

[0015] like figure 1 As shown, the prefabricated component maintenance tarpaulin automatic retracting device of this embodiment includes a bracket, and the bracket includes a first bottom plate 11, a second bottom plate 12, a first longitudinal bar 13, a second longitudinal bar 14, and a third longitudinal bar. 15. The fourth longitudinal bar 16, the first transverse bar 17 and the second transverse bar 18, between the first longitudinal bar 13 and the second longitudinal bar 14, between the third longitudinal bar 15 and the fourth longitudinal bar 16 Diagonal struts 19 are provided, reinforcement bars 20 are arranged between the first cross bar 17 and the first longitudinal bar 13 and between the first cross bar 17 and the fourth longitudinal bar 16, and the second cross bar 18 and the second longitudinal bar A reinforcing rod 20 is provided between the rod 14, the second cross bar 18 and the third longitudinal bar 15, and an oilcloth roll supporting device is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com