Densification process for preparing high-volume-fraction SiCp/Al composite material

A composite material and densification technology, applied in the field of powder metallurgy, can solve the problems of poor interface bonding, poor density, and difficult to control, and achieve the effect of avoiding poor interface bonding and excellent thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12 and comparative example 1-6

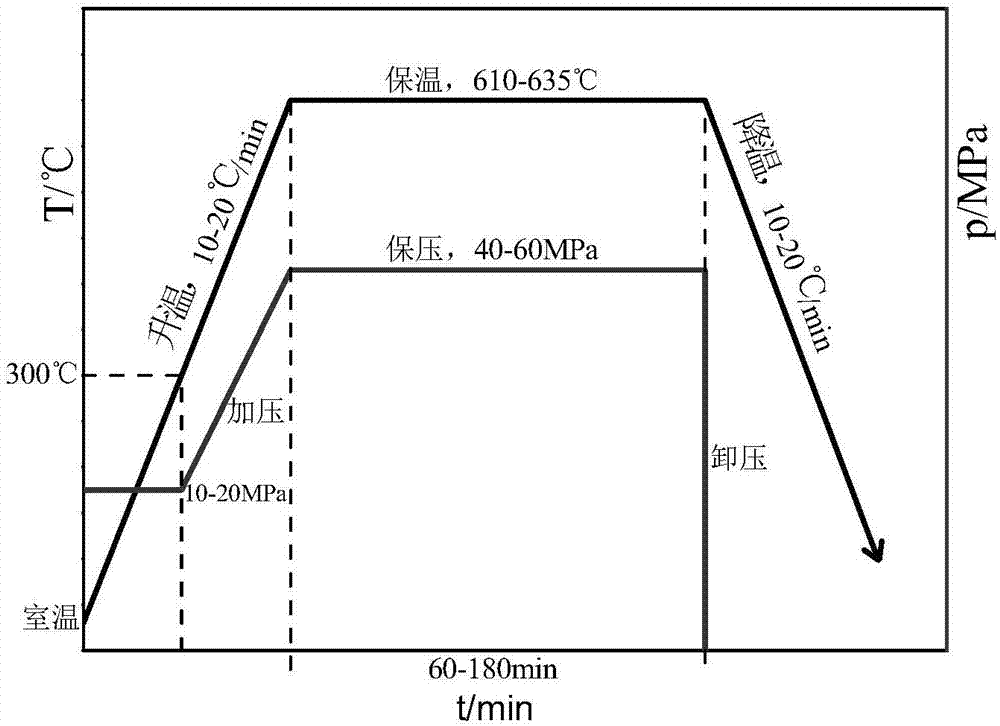

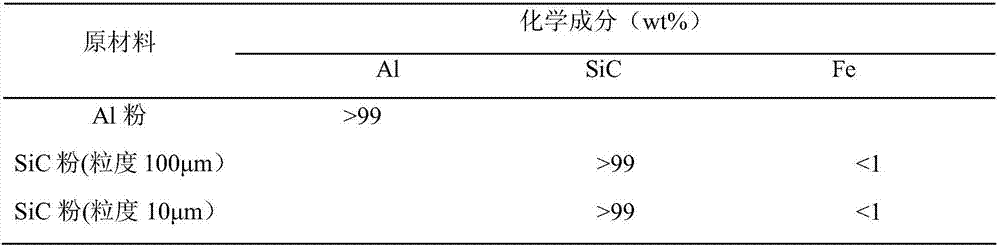

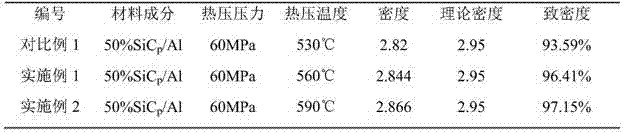

[0025] Raw aluminum powder and SiC powder with an average particle size of 8 μm and SiC powder (with an average particle size of 100 μm and 10 μm mixed in a ratio of 10:4) were dried in a vacuum drying oven at 110 ° C for 2 hours. The SiC powder and the aluminum powder are added into a ball mill according to a certain volume percentage for mixing at a speed of 280 r / min, and the mixing time is 2 hours. The mixed powder mixed by ball mill is put into the mold for cold pressing and forming, and the cold compact is put into the vacuum hot press for hot pressing and sintering, wherein the pressure is applied during the heating process of hot pressing and sintering, from the beginning of heating to During the period of reaching about 300°C, apply a pressure of 15MPa. During the period of pressurization from about 300°C to the hot-pressing temperature, the pressure gradually increases from 15MPa to 60MPa. The time for pressurizing to the hot-pressing pressure is 10 minutes; the time...

Embodiment 13-24

[0031] Operated as in the above example, the material composition, hot pressing pressure, and hot pressing temperature are shown in Table 3.

[0032] table 3

[0033]

[0034]

[0035] 60% SiC from Table 3 p The change data of the density of the / Al composite material can be seen: when the forming pressure is 50 MPa, the density of the 60% SiCp / Al composite material reaches 98.93%, which is the highest compared with other processes under hot pressing pressure. 70%SiC p The content of silicon carbide particles in the / Al composite material is too high, so the applied thermal pressure mainly acts on the silicon carbide particles. As the hot pressing pressure of the material continues to increase, the greater the force acting on the reinforcing particles, resulting in more silicon carbide particles being crushed, the material density decreases, so the better hot pressing pressure at 620°C is 40MPa.

Embodiment 25-30

[0037] Operate as in the above example, but set the hot pressing process conditions at 620°C and 50MPa, and use different volume fractions of SiC p / Al composite material, the results are shown in Table 4.

[0038] Table 4

[0039]

[0040] As shown in Table 4, SiC with different SiC volume fractions prepared under the same hot pressing process is given. p / Al composite density data. It can be seen that as the content of silicon carbide particles increases, the density of the composite material decreases from 99.69% to 94.14%, showing a gradual downward trend. Since the strength and hardness of silicon carbide particles are much higher than that of pure aluminum matrix, as the content of silicon carbide increases, more external loads act on the reinforcement particles, which changes the overall mechanical properties of the composite material, especially the The hardness of the composite material increases linearly as a function of the silicon carbide particle content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com