Boiler chimney capable of recovering smoke gas waste heat

A flue gas waste heat and flue gas heat exchange technology, applied in the field of boiler chimneys, can solve the problems of not having a flue gas waste heat recovery device, environmental heat pollution, dust impurities polluting the atmospheric environment, etc., to avoid thermal pollution, improve thermal efficiency, buffer long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

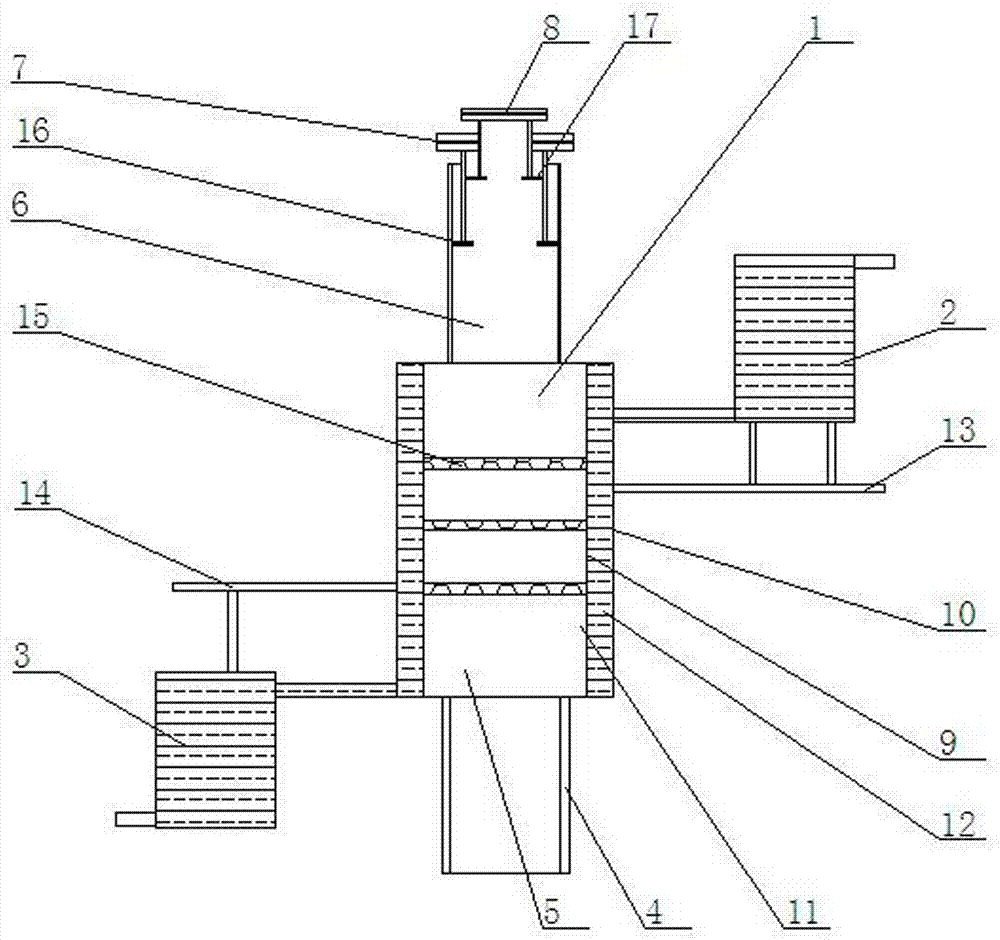

[0014] Such as figure 1 As shown, a boiler chimney that can recover flue gas waste heat includes a chimney body 1, a cold water supply tank 2, and a warm water collection tank 3. 6. A large chimney cover 7 and a small chimney cover 8 are formed. The chimney inlet 4 is welded on the bottom surface of the flue gas heat exchange tube 5, the exhaust tube 6 is welded on the top surface of the flue gas heat exchange tube 5, and the large chimney The cover 7 is installed at the upper end of the exhaust pipe 6, and the small chimney cover 8 is installed at the upper end of the large chimney cover 7; the flue gas heat exchange cylinder 5 is composed of an inner cylinder 9 and an outer cylinder 10, and the outer cylinder 10 is welded On the outer wall of the inner cylinder 9, the inside of the inner cylinder 9 is a smoke chamber 11, and a water exchange chamber 12 is formed between the inner cylinder 9 and the outer cylinder 10; the upper right end of the outer cylinder 10 is install...

Embodiment 2

[0016] Such as figure 1 As shown, the inner cylinder body 9 of the flue gas heat exchange cylinder 5 is equipped with upper and lower three layers of stainless steel metal filter screens 15 .

Embodiment 3

[0018] Such as figure 1 As shown, a large circular metal plate 16 is installed on the inner upper end wall of the exhaust pipe 6, and the large chimney cover 7 is composed of a top cover and a support frame. A circular opening is arranged on the top cover of the large chimney cover 7, and the support The frame is supported on the large circular metal plate 16; the upper end of the internal support frame of the large chimney cover 7 is welded with a small circular metal plate 17, the small chimney cover 8 is composed of a top cover and a support frame, and the bottom of the small chimney cover 8 The end is supported on the small circular metal plate 17 inside the large chimney cover 7 by a support frame.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap