Heat conduction oil heater

A heat transfer oil heater and heater technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of complex structure of closed systems and easy oxidation of open systems by air, and save energy. Operation cost, avoid furnace tube coking, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

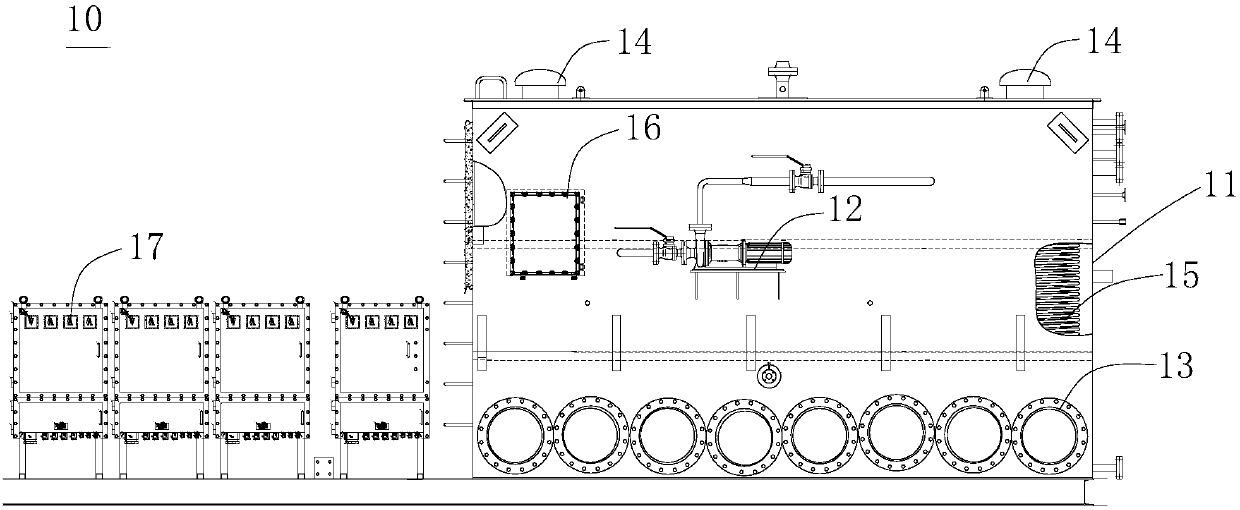

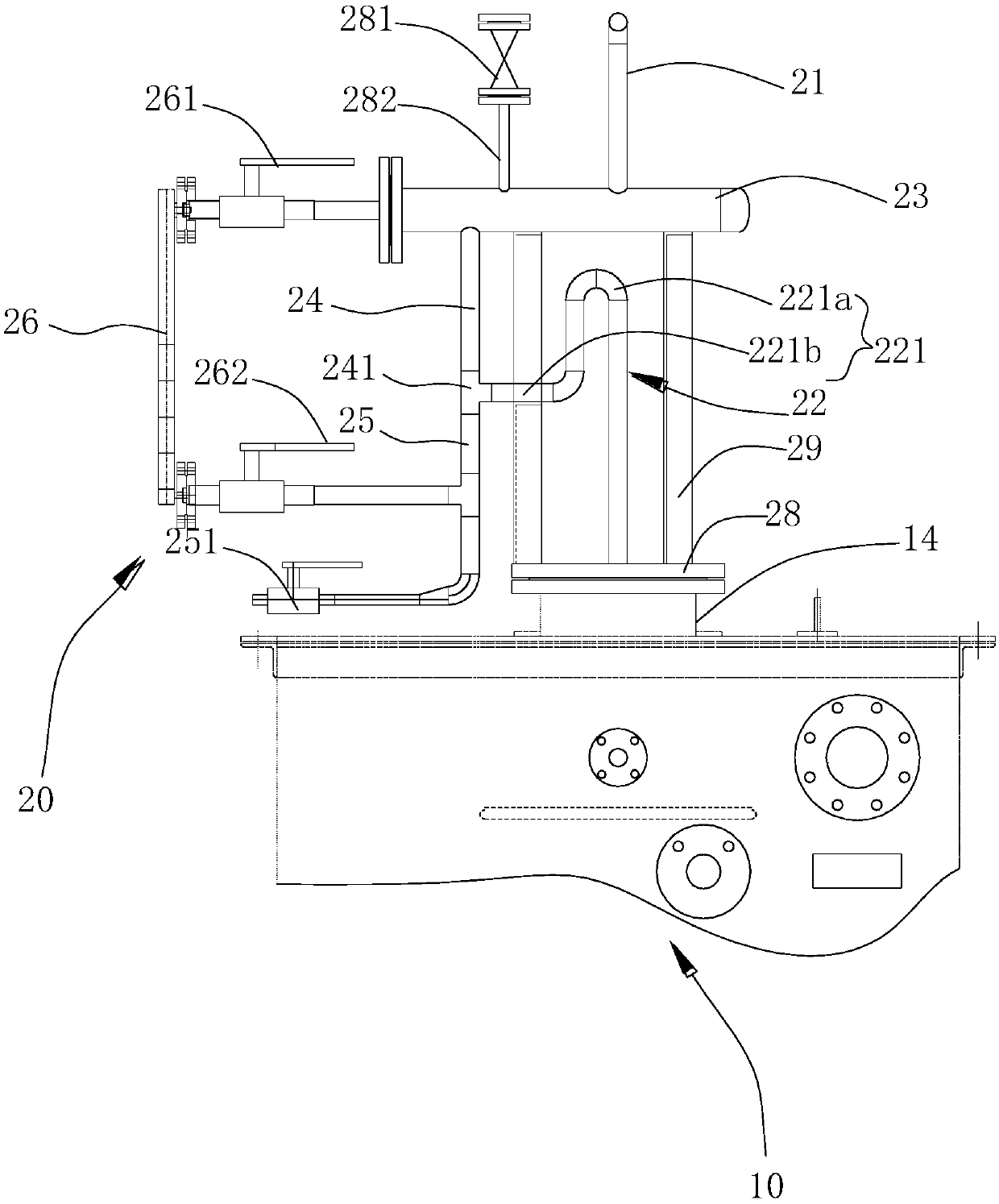

[0032] Such as figure 1 with figure 2 as shown, figure 1 For the heat conduction oil heater of the present invention, only the structural schematic diagram of the heater body is shown, figure 2 A structural schematic diagram showing the oil seal device and part of the heater body for the heat-conducting oil heater of the present invention. The heat conduction oil heater includes a heater body 10 and an oil sealing device 20 , and the oil sealing device 20 is arranged on the exhaust port 14 of the heater body 10 .

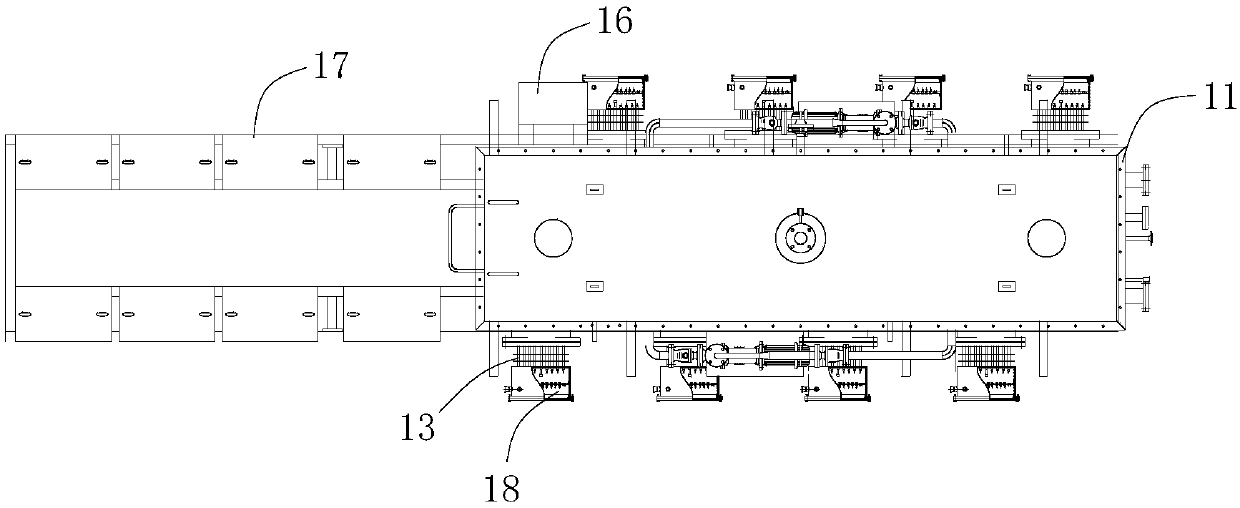

[0033] combine image 3 as shown, image 3 It is a top view of the heater body. The heater body 20 includes an oil tank 11 , a circulation pump 12 located in the oil tank, an electric heating coil 13 for heating the heat conduction oil in the o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap