High precision punching device for printing

A punching device and high-precision technology, which is applied in metal processing and other directions, can solve the problems of printed matter not meeting the process requirements and inaccurate punching, and achieve the effect of avoiding wear and flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

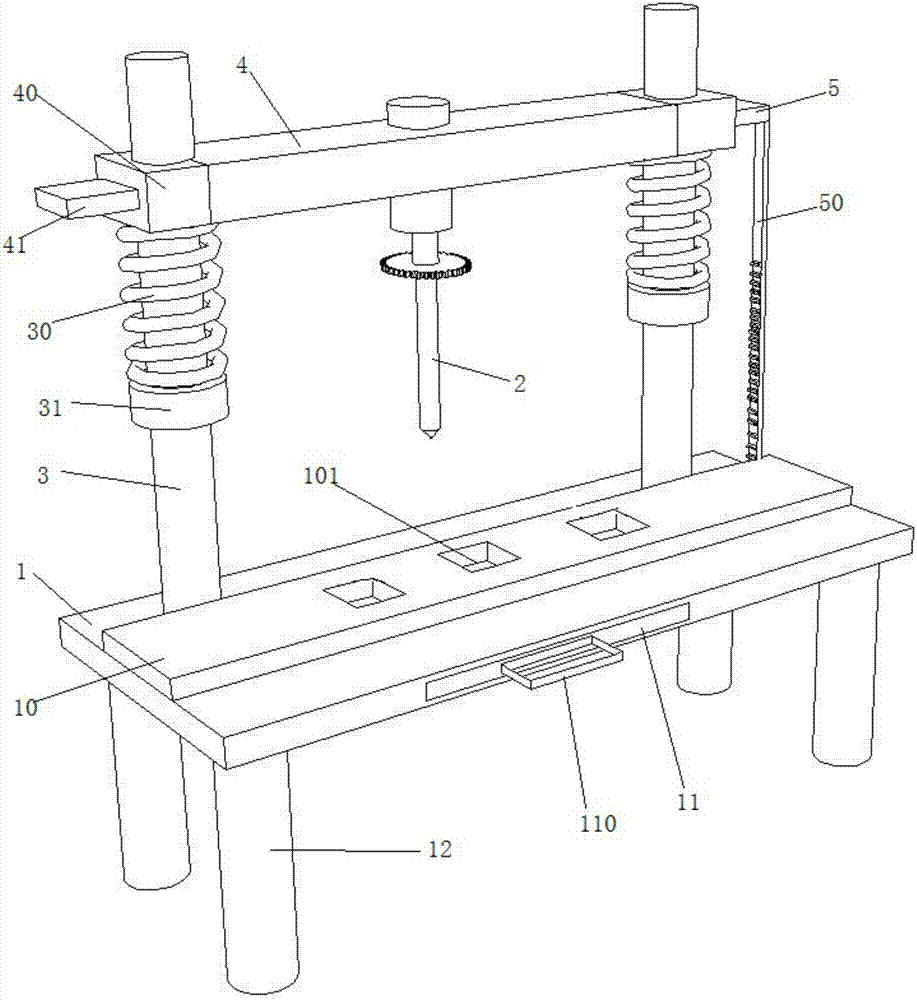

[0019] Example 1

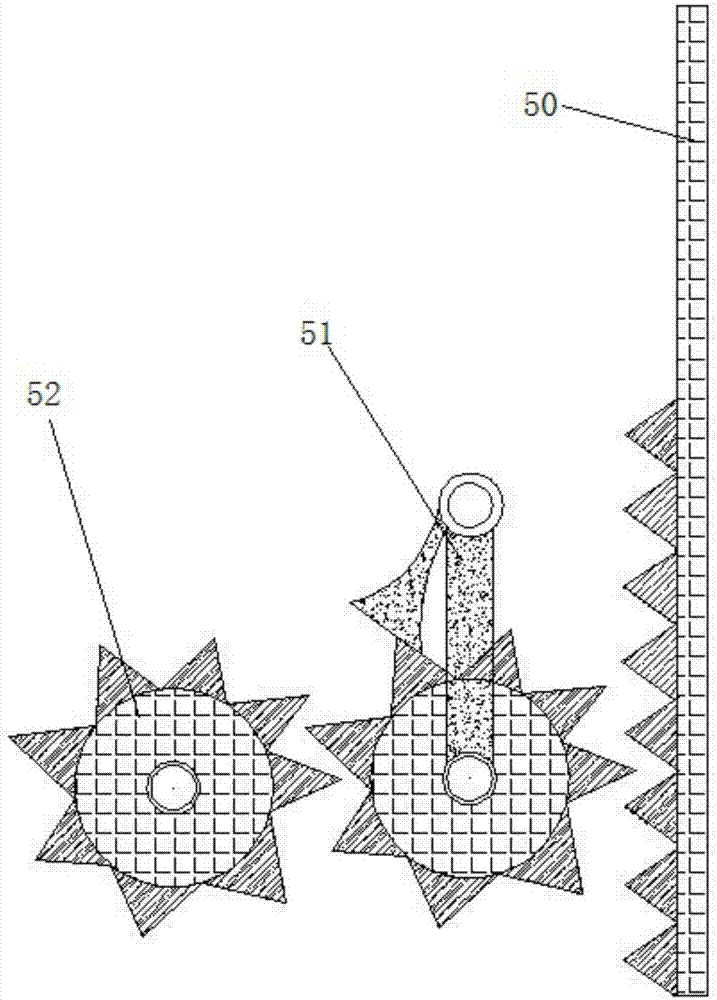

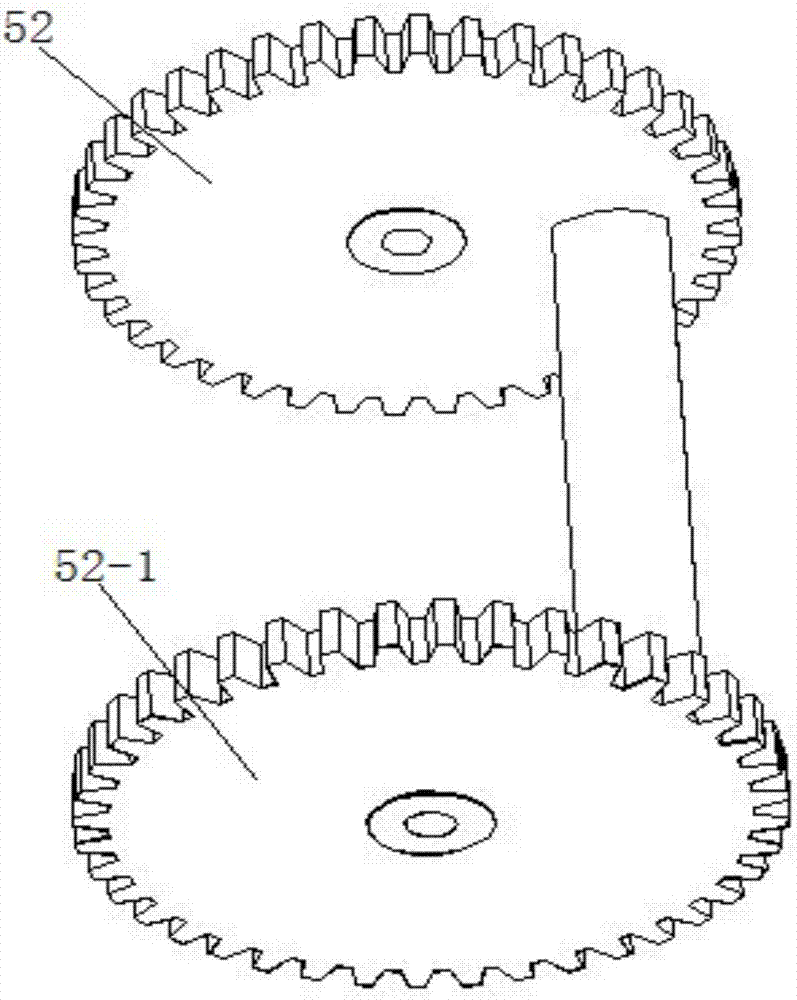

[0020] Such as Figure 1-4 As shown, a high-precision printing and punching device includes a workbench 1, a drill bit, a conveyor belt 10 arranged on the workbench 1, and the conveyor belt 10 is provided with a plurality of punching slots 101; it also includes a workbench 1 The upper support frame 3, the movable plate 4 arranged on the support frame 3; both sides of the movable plate 4 are fixedly installed with fixed rings 40, the two fixed rings 40 are respectively sleeved on the support frame 3, and the support frame 3 is sleeved on A first spring 30 is connected, one end of the first spring 30 is connected with the fixed ring 40, and the other end of the first spring 30 is connected with a limit block 31 fixed on the support frame 3; the outer side of one of the fixed rings 40 is fixedly connected There is a pressing rod 41, and the outer surface of the other fixed ring 40 is fixedly connected with a driving device 5; the driving device 5 includes a first...

Example Embodiment

[0022] Example 2

[0023] Such as figure 2 As shown, on the basis of the high-precision printing and punching device described in Embodiment 1, a paper delivery drawer 11 is arranged inside the worktable 1, and the paper delivery drawer 11 is facing the punching slot 101, and the paper delivery A pull ring 110 is provided on the outer wall of the drawer 11. The setting of the paper delivery drawer 11 can collect the paper scraps generated during the punching process, and prevent the paper scraps from flying around and polluting the workbench.

Example Embodiment

[0024] Example 3

[0025] Further optimized on the basis of the high-precision printing and punching device described in Embodiment 1, the four corners of the bottom end of the worktable 1 are all provided with supporting legs 12. The setting of the support foot stand 12 prevents the bottom surface of the workbench 1 from being worn away, and at the same time, improves the level of the workbench, and prevents the first rack 50 from touching the workbench 1 when it moves down, causing damage to the first rack. .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap