Multiphase Cyclone Separation Units and Cyclone Separators

A technology of flow separation and phase swirl, which is applied to swirl devices, devices whose axial directions of swirl can be reversed, etc. The composition is simple, the effect is good, and the material is easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

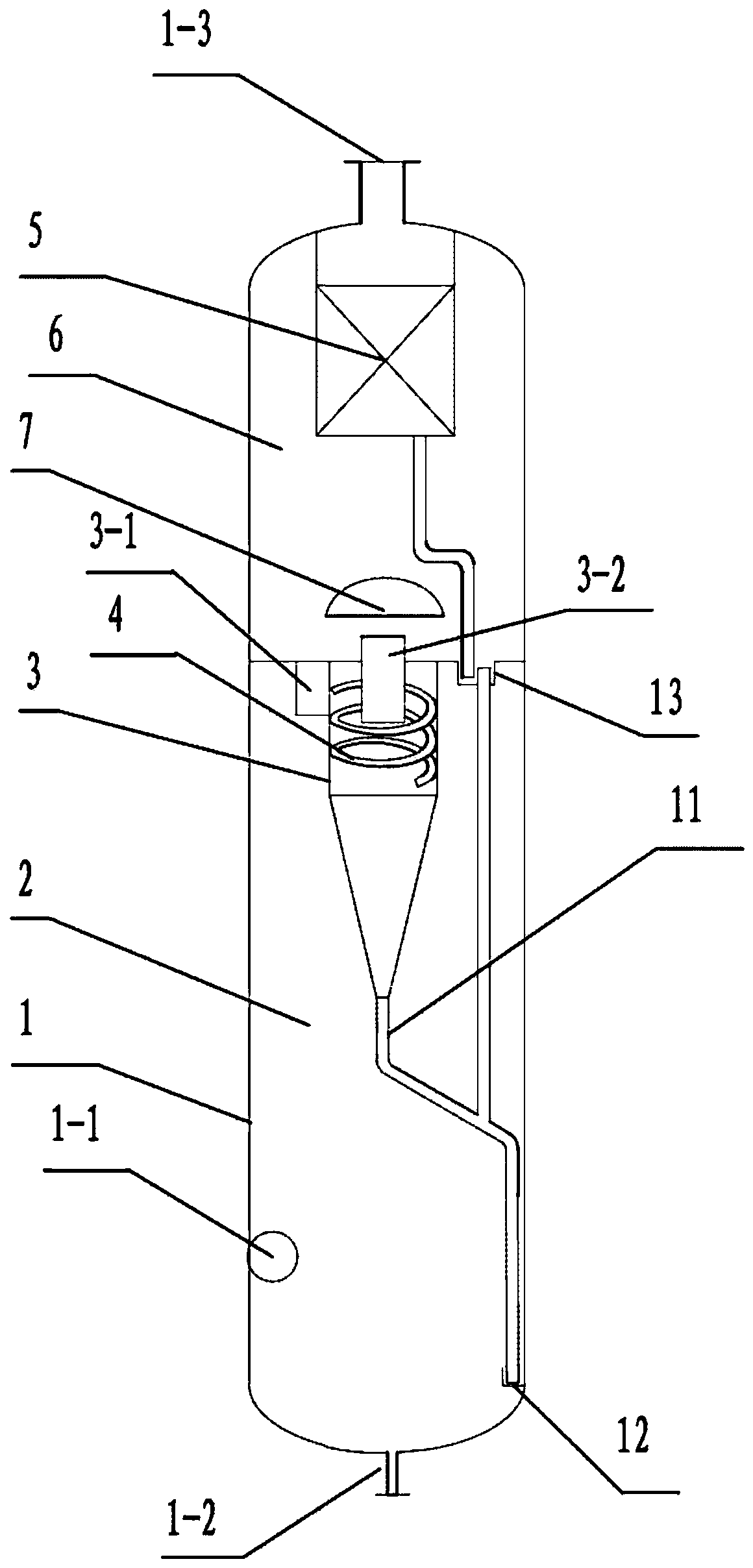

[0057] The above-mentioned cyclone separator is applied to a slurry bed reactor as a gas-liquid-solid three-phase separation device. The operating conditions of the cyclone separator are: pressure 3.0MPa, temperature 220°C, the total content of liquid mist and catalyst carried out by the gas is about 200g / m 3 , Catalyst particle size range 0 ~ 20μm.

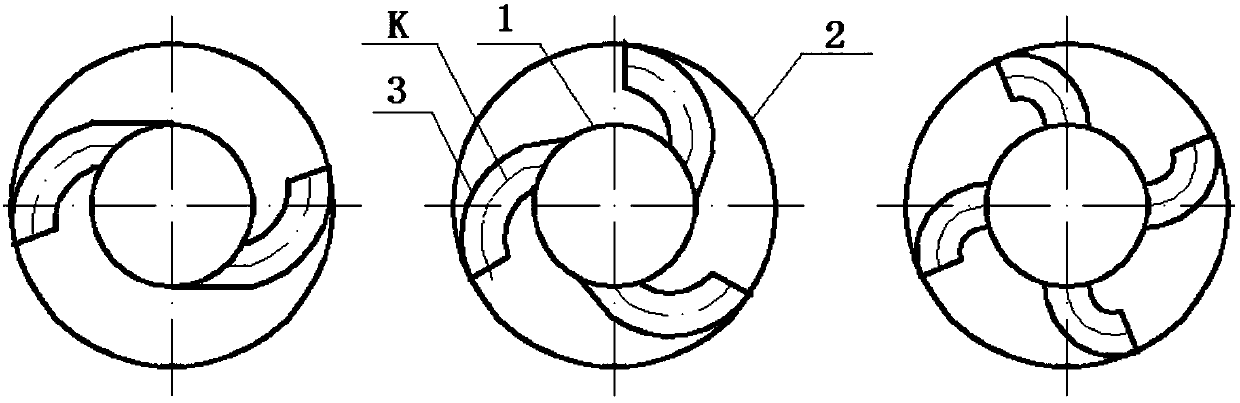

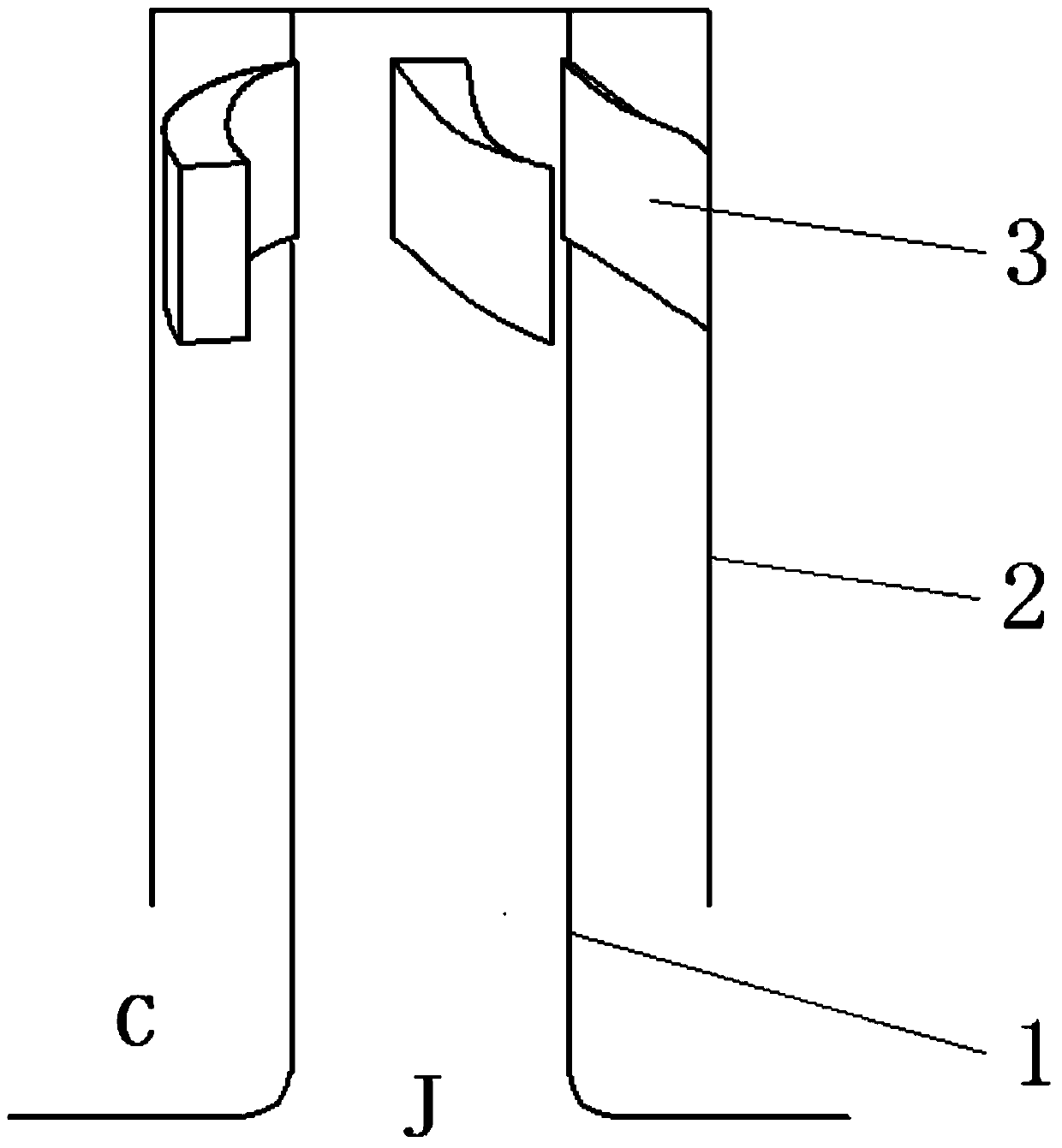

[0058] The specifications and dimensions of the multiphase cyclone separation unit are as follows: 4 swirl generation tubes are used, the diameter of the inner tube 1 is d=18mm, the diameter of the outer tube 2 is D=45mm, and the size of the rectangular section of the swirl generation tube is A×B =10mm×3.3mm, the cross-sectional area of the annular space S=1335mm 2 , the intake gas velocity V at the inlet J i =7.9m / s, the superficial gas velocity V of the annular space 0 = 1.5m / s. The downward spiral inclination angle of the swirl flow generating pipe 3 is 0°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com