A high-altitude cable snow removal device

A cable and cylinder technology, which is applied in the field of high-altitude cable snow removal devices, can solve problems such as disconnection, time-consuming and labor-intensive effects, and poor effects, and achieve the effects of easy calculation of height, high degree of automation, and enhanced practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The following is a description of Embodiment 1.

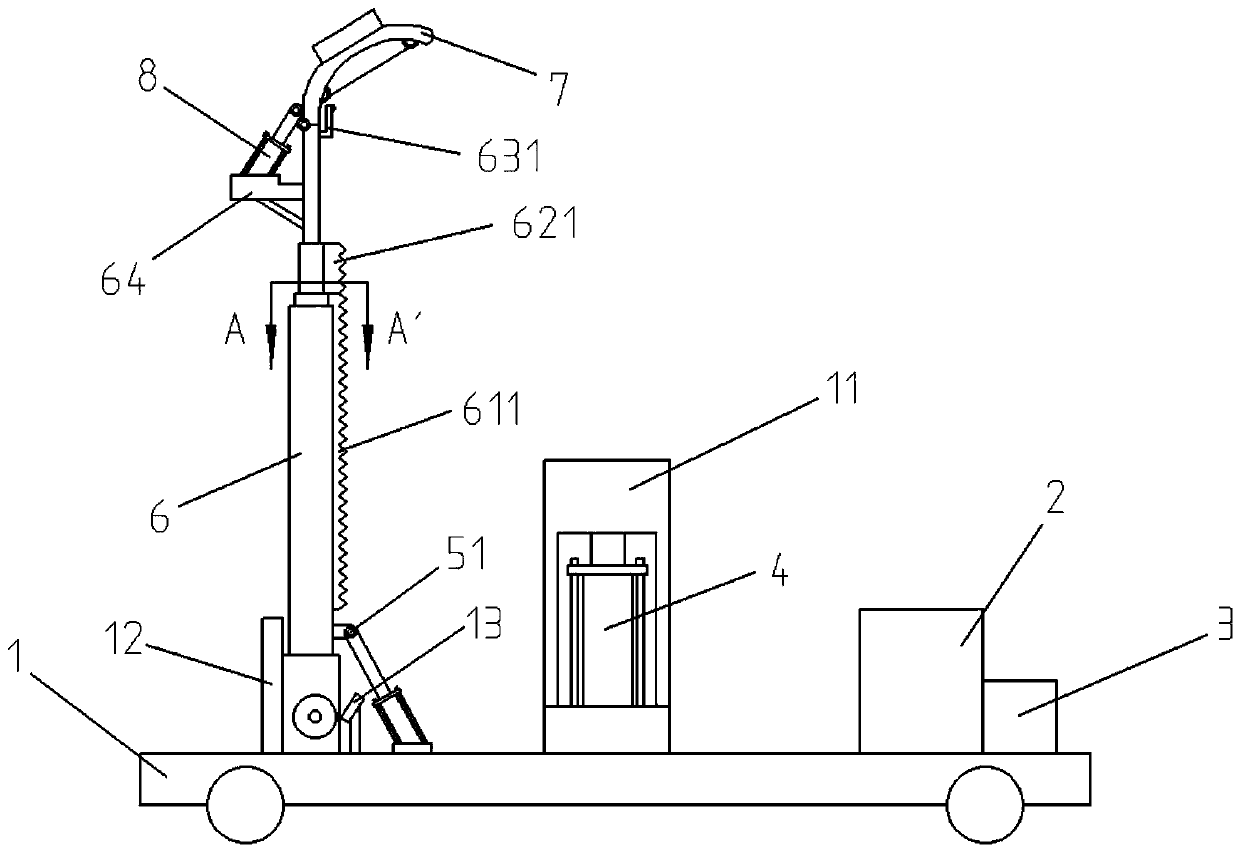

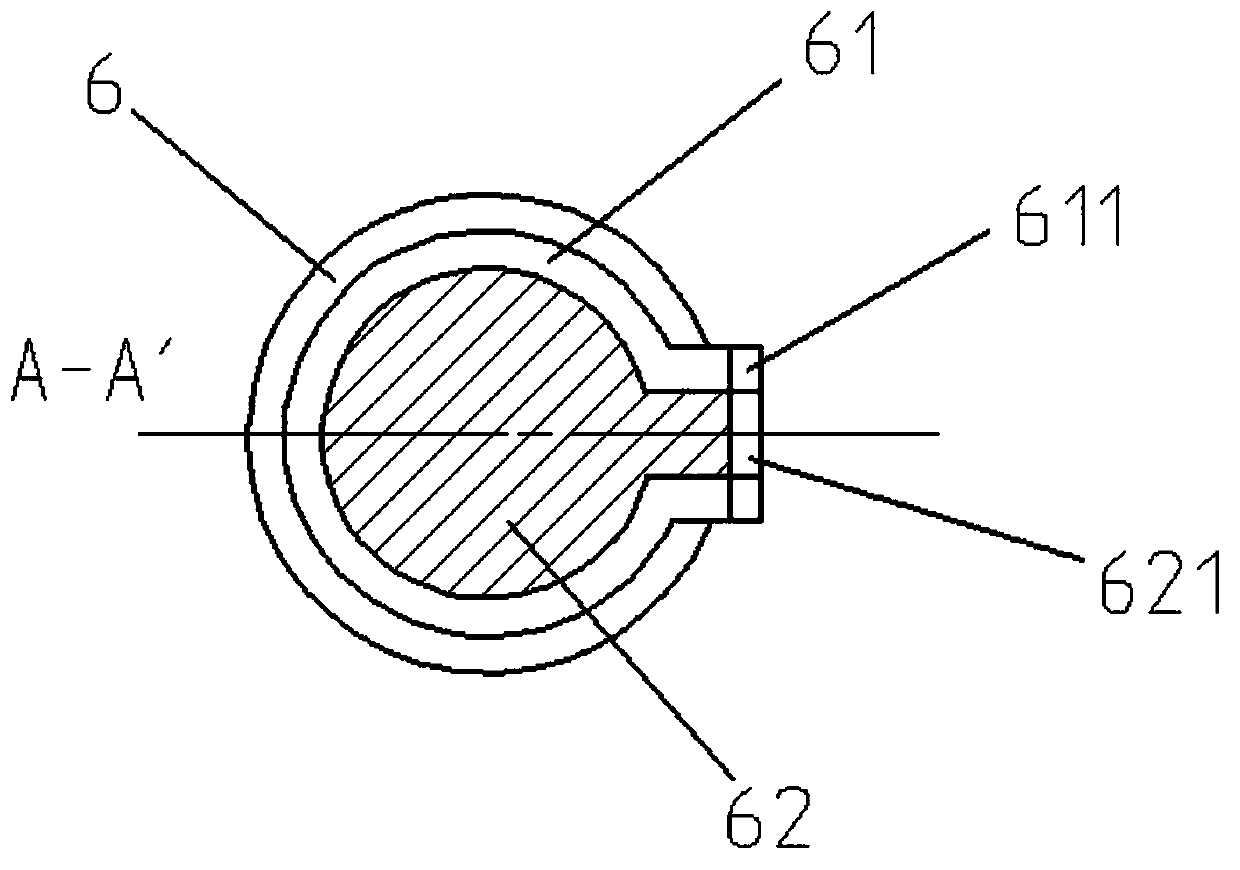

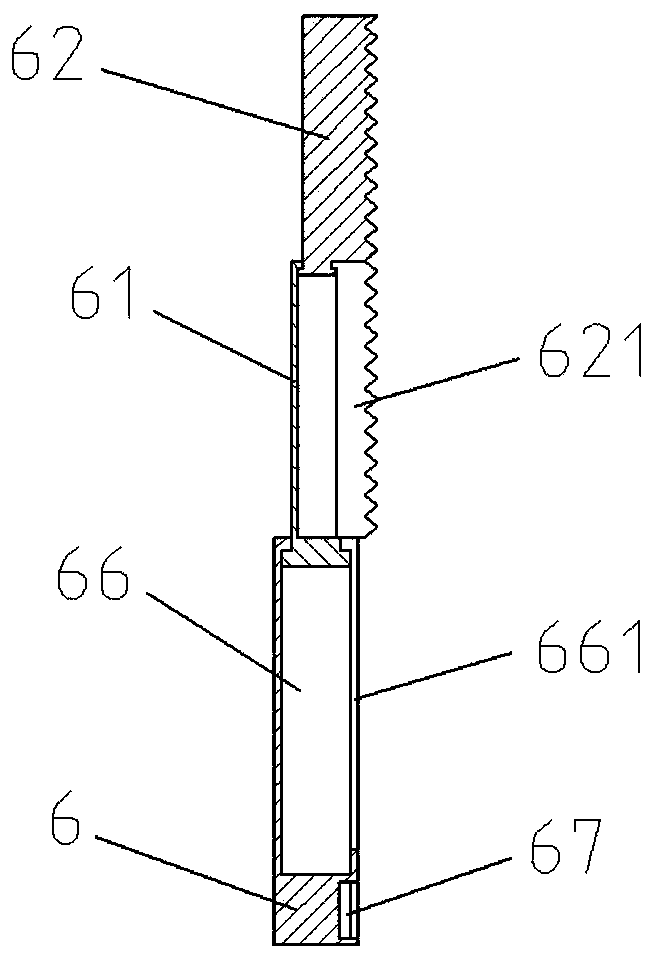

[0032] Such as Figure 1 to Figure 7 As shown, a high-altitude cable snow removal device includes a chassis 1, a protective plate 11, a baffle plate 12, a limit plate 13, a fixing groove 14, a power supply 2, a single-chip microcomputer system 3, a driving cylinder 4, a rotary rod cylinder 5, and a rotary rod Shaft 51, rotating rod slider 52, telescopic bottom rod 6, telescopic middle rod 61, side rack 611, telescopic ejector rod 62, middle rack 621, positioning rod 63, connecting rod 631, infrared sensor 632, cylinder fixing frame 64. Reinforcement rod 65, telescopic rod groove 66, holding notch 661, slide rail groove 67, snow removal body 7, installation block 71, snow removal rope 72, snow removal shaft 73, snow removal cylinder 8, snow removal rod shaft 81, snow removal slider 82. Rotary motor 9, drive gear 91, the bottom of the chassis 1 is provided with rollers, one side of the top is provided with a power supply ...

Embodiment 2

[0036] The following is a description of Embodiment 2.

[0037] In embodiment 2, for the same structure as in embodiment 1, the same symbols are given, and the same description is omitted. Embodiment 2 is improved on the basis of embodiment 1, and the bottom of chassis 1 is provided with a motor and a reducer. The reducer is connected with the roller, and the motor switch is set on the power supply 2, so the degree of automation is higher.

[0038]When the device is in use, after the device is moved to a predetermined position, the power supply 2 is turned on, the switch of the single-chip microcomputer system 3 is turned on, and the cylinder 4 is driven to extend to the maximum thread, and the snow removal cylinder 8 is retracted to drive the snow removal body 7 to turn upwards, and at the same time, the rod cylinder 5 Pull to the shortest thread, the telescopic bottom rod 6 contacts the limit plate 13, and the top side of the middle rack 621 on the telescopic ejector rod 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com