Housing, manufacturing method thereof, and mobile terminal

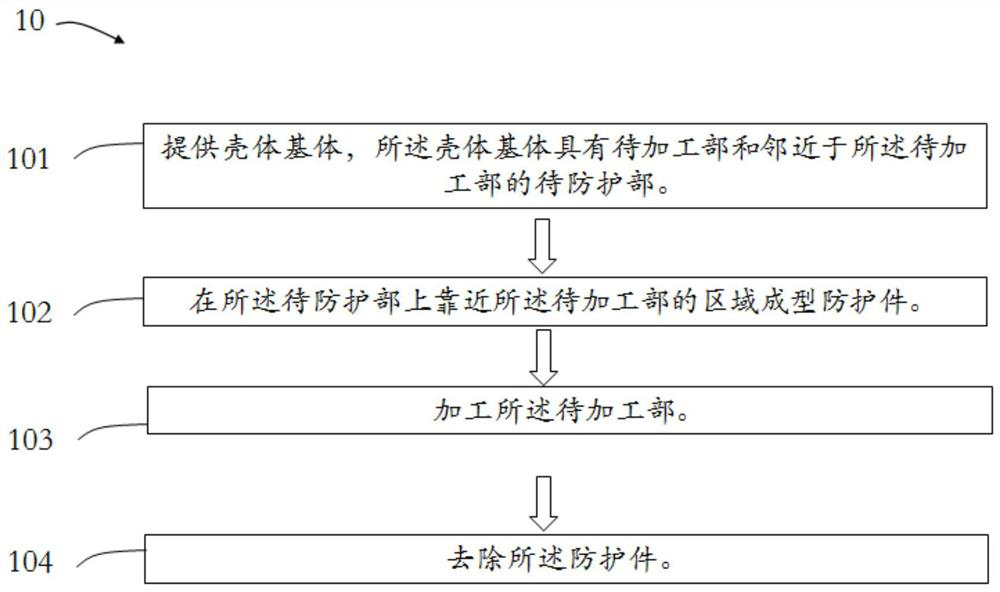

A manufacturing method and mobile terminal technology, applied in the direction of casing/cabinet/drawer components, etc., can solve the problems of reducing the processing efficiency of the casing, economic loss, etc., and achieve the goal of ensuring structural integrity and structural accuracy and reducing impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0071] Step 104, the step of removing the protection member includes the following steps.

[0072] Step 41: Spray liquid on the protective element, wherein the protective element is compatible with the liquid.

[0073] In one embodiment, the material of the protective member 140 is hydrosol. The water sol is sprayed on the protected area 132 of the portion to be protected 130 to form the protective member 140 on the protected area 132 . Hydrosols can be emulsified from acrylic or polyurethane resins. A hydrosol can be dissolved in water or a solution containing water.

[0074] In another embodiment, the protective member 140 is made of oil glue. The main component of oil glue can be acrylic or polyurethane, which can be dissolved with oily solvents (such as toluene, DMF, butanone, etc.).

[0075] Step 42, removing the liquid and the protective element 140 dissolved in the liquid.

[0076] In one embodiment, in the step of removing the protection member 140 , water is used...

no. 2 example

[0079] Step 104, the step of removing the protection member includes the following steps.

[0080] Step 51 , heating the protective element, so that the protective element is in a molten state.

[0081] In this embodiment, the material of the protective member 140 is hot melt. Hot melt adhesive is a thermoplastic resin, the main component may be polyvinyl butyral (PVB), which can be dissolved in methanol / ethanol / ether solvents.

[0082] Step 52, removing the protective member in molten state.

[0083] The step of removing the protection member 140 includes: removing the protection member 140 by heating and wiping.

no. 3 example

[0085] Step 104 , in the step of removing the protective piece 140 , the protective piece 140 is peeled off from the portion to be protected 130 , and the protective piece 140 is peelable glue.

[0086] In this embodiment, the protection member 140 is peeled off from the portion to be protected 130 . The peelable glue can be sprayed on the protected area 132 of the part to be protected 130 as a protective coating to form a layer of protective coating, which is quickly dried at room temperature. After drying into a film, it can be completely peeled off from the part to be protected 130 , without water and solvent cleaning, simple process.

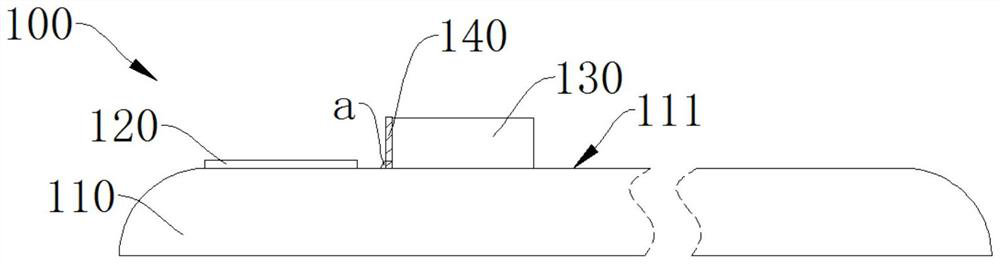

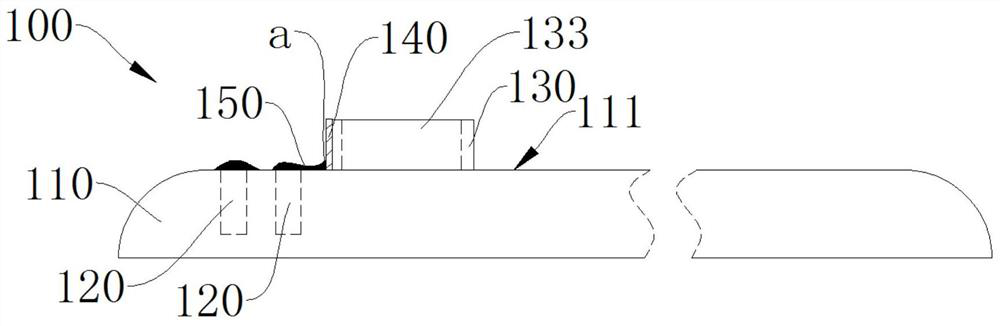

[0087] see Figure 11 , Figure 11 It is a housing 100 provided in the embodiment of this application. The casing 100 is made by using the casing manufacturing method 10 described in any one of the above-mentioned embodiments.

[0088]The housing 100 includes a housing base 110 . The housing base 110 has a top wall 111 . The portion to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com