Hydraulic system with clutch actuation to minimize pump losses

A technology of clutch control and hydraulic system, applied in the field of hydraulic system, can solve problems such as lack of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

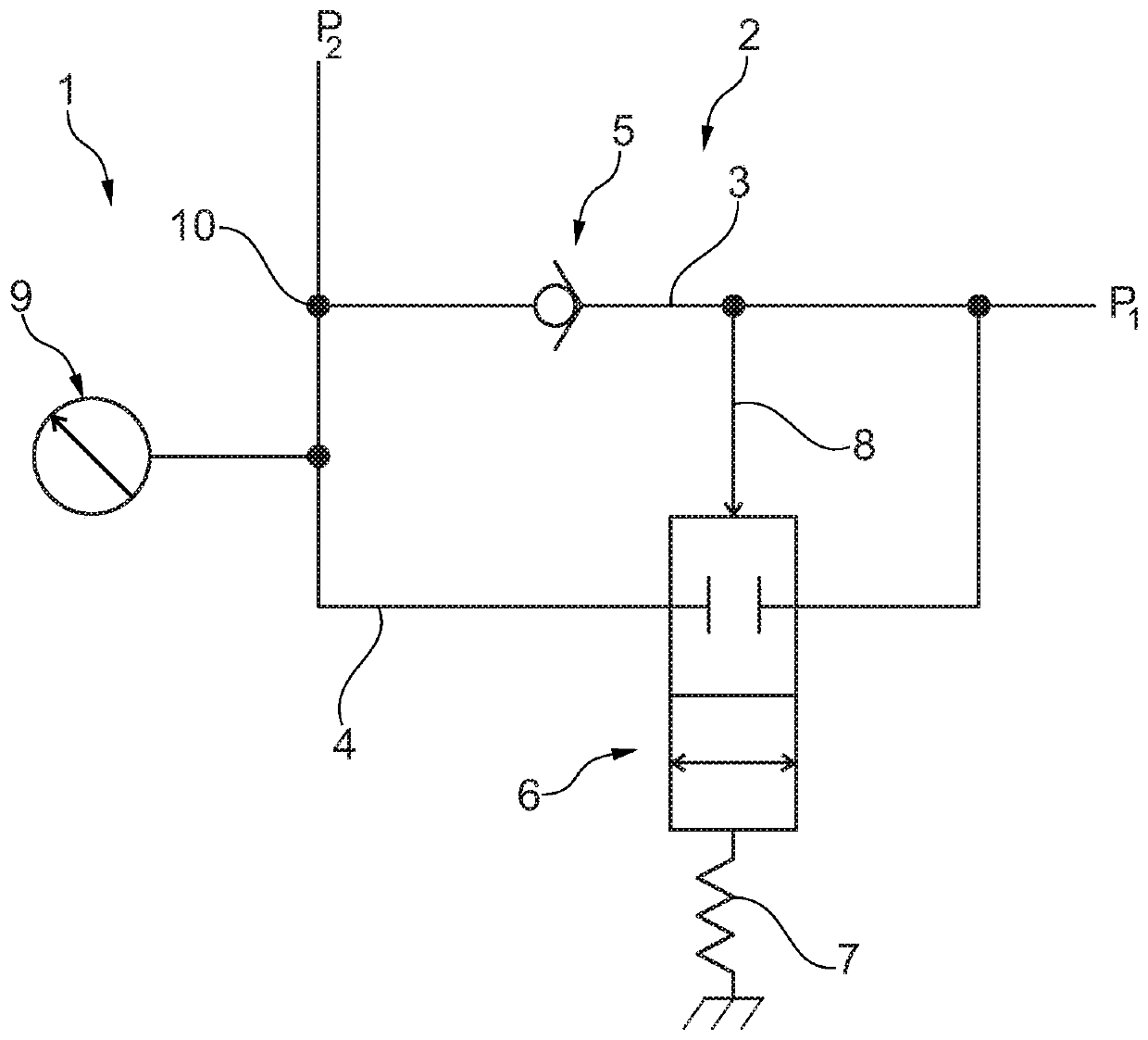

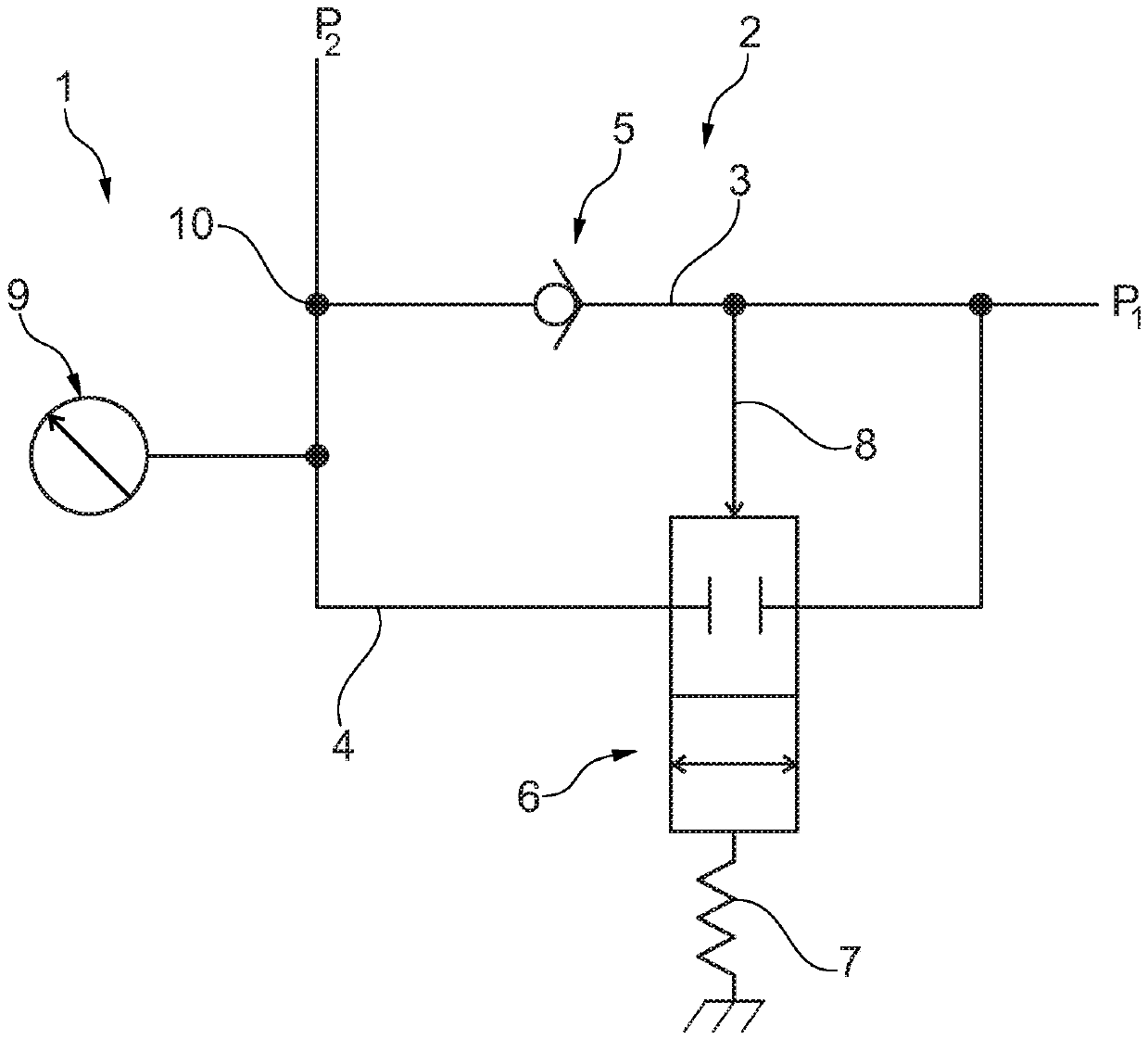

[0023] exist figure 1 A hydraulic system 1 according to the invention is shown in . A clutch actuation pressure p2 , ie the pressure that is required to actuate the clutch on the pressure chamber side, acts on the side of the hydraulic clutch actuator (not shown). The clutch itself is also not shown.

[0024] The hydraulic system 1 has a line complex 2 with a hydraulic pump (not shown) at the end, which supplies a pump pressure p1. A pressurized fluid (such as a liquid, for example oil) put under pressure by a hydraulic pump passes through the pipeline complex 2 (ie the first pipeline branch 3 and / or the second pipeline branch 4) towards the not shown clutch actuator. direction delivery. The non-return valve 5 is arranged in the first line branch 3 in such a way that it closes the passage when the pressure p1 falls below the value of p2.

[0025] In the second line branch 4 a valve 6 is used, namely a slide valve. The valve 6 is designed as a 2 / 2-way valve of the slide va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com