Carding machine

A carding machine and carding technology, applied in the field of carding machines, can solve the problems of affecting carding efficiency, waste of raw materials, and poor feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

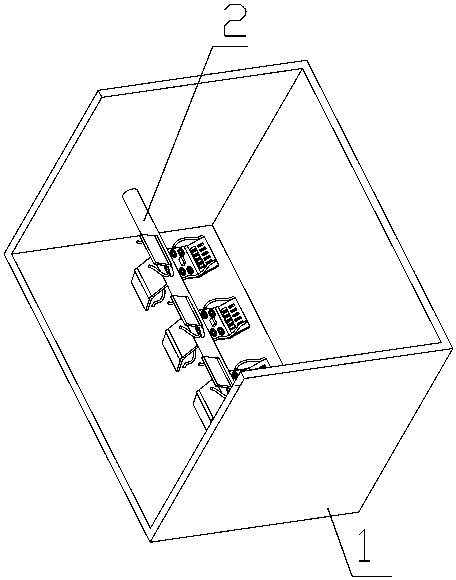

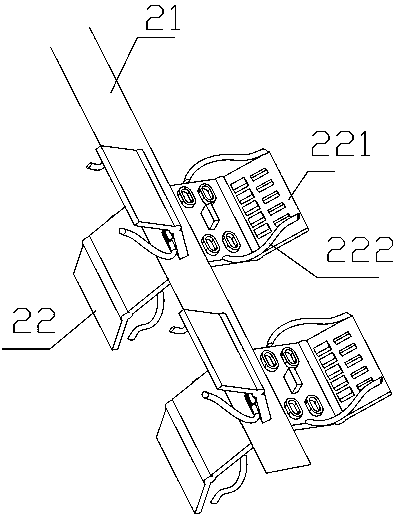

[0031] Example 1, such as figure 1 — Figure 4 Shown: a carding machine, a storage box and a carding device 3, the storage box includes a storage rack 1 and a material shifting device 2 located inside the storage rack 1, the material shifting device 2 includes a material shifting shaft 21 and is connected to the shifting shaft 21 At least two groups of paddle assemblies 22 in different positions, each group of paddle assemblies 22 all include a central wide paddle 221 and material forks 222 located on both sides of the central wide paddle 221, and the extension direction of the central wide paddle 221 is The radial direction of the material rotating shaft 21.

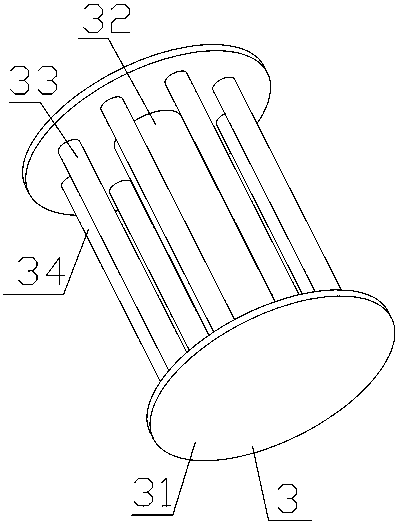

[0032] As a preferred embodiment of the present invention, the combing device 3 includes a main shaft 32 , a connecting disc 31 connected to both sides of the main shaft 32 and rotating around the main shaft 32 , and a combing wheel mounted on the connecting disc 31 .

[0033] As a preference of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com