Composite ceramic material and preparation method thereof

A technology of composite ceramics and porcelain stone, applied in the field of materials, can solve problems such as hearing loss, many hazards, and depression, and achieve the effects of strong sound absorption, good mechanical properties, and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

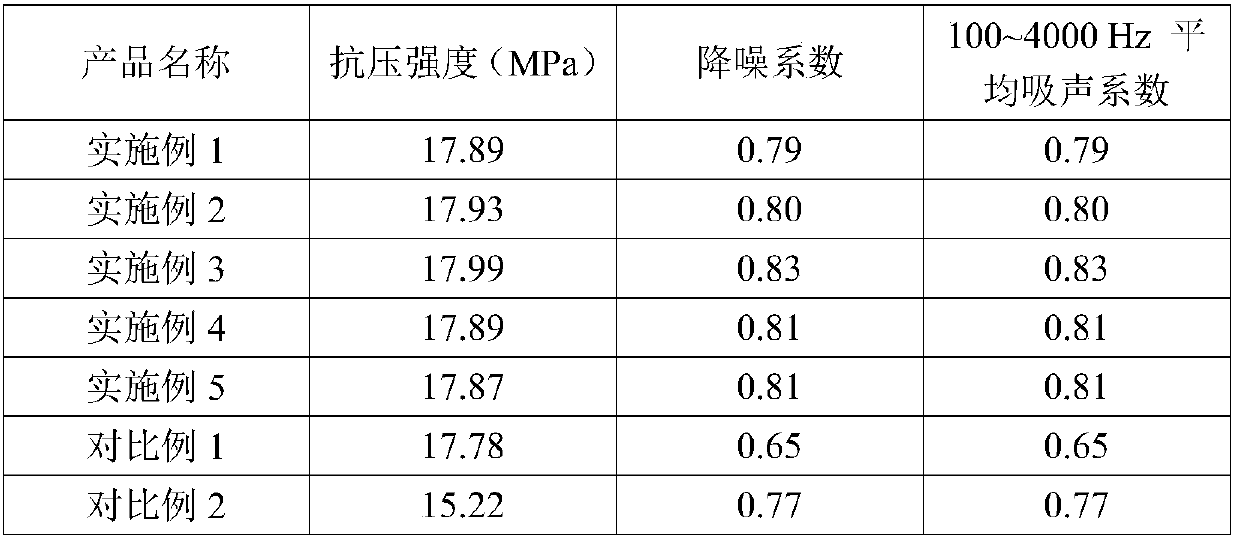

Examples

Embodiment 1

[0020] A composite ceramic material, prepared from the following ingredients in parts by weight: 20 parts of porcelain stone, 10 parts of pyrophyllite, 10 parts of quartz sand, 1 part of polyethylene oxide, 0.5 part of titanium dioxide, cetyl trimethyl 0.1 part of ammonium chloride, 1 part of sodium alginate, 0.1 part of diphenylamine, 0.2 part of sodium hexametaphosphate, 0.5 part of polyvinylpyrrolidone, 1 part of sheep oil, 0.5 part of cinnamon oil, 1 part of polyanionic cellulose, sodium silicate 0.1 part, polyoxyethylene sorbitan laurate 1 part, acrylic milk mortar 0.5 part, water 5 parts.

[0021] The preparation method of above-mentioned composite ceramic material is:

[0022] Step 1: Grind porcelain stone, pyrophyllite and quartz sand into powder and mix them;

[0023] The second step: mix polyethylene oxide, polyanionic cellulose, sodium alginate and water, and stir for 10 minutes to form a paste;

[0024] Step 3: Mix all the components, put them into the ball mill ...

Embodiment 2

[0031] A composite ceramic material, prepared from the following components in parts by weight: 25 parts of porcelain stone, 15 parts of pyrophyllite, 12 parts of quartz sand, 1.5 parts of polyethylene oxide, 0.5 part of titanium dioxide, cetyl trimethyl 0.1 parts of ammonium chloride, 1.2 parts of sodium alginate, 0.13 parts of diphenylamine, 0.3 parts of sodium hexametaphosphate, 0.6 parts of polyvinylpyrrolidone, 1.2 parts of sheep oil, 0.6 parts of cinnamon oil, 1-2 parts of polyanionic cellulose, silicon 0.15 parts of sodium nitrate, 1.3 parts of polyoxyethylene sorbitan laurate, 0.6 parts of acrylic milk mortar, and 6 parts of water.

[0032] The preparation method of above-mentioned composite ceramic material is:

[0033] Step 1: Grind porcelain stone, pyrophyllite and quartz sand into powder and mix them;

[0034] The second step: mix polyethylene oxide, polyanionic cellulose, sodium alginate and water, and stir for 12 minutes to form a paste;

[0035] Step 3: Mix al...

Embodiment 3

[0042] A composite ceramic material, prepared from the following components in parts by weight: 30 parts of porcelain stone, 20 parts of pyrophyllite, 15 parts of quartz sand, 2 parts of polyethylene oxide, 0.75 parts of titanium dioxide, cetyl trimethyl 0.15 parts of ammonium chloride, 1.5 parts of sodium alginate, 0.15 parts of diphenylamine, 0.35 parts of sodium hexametaphosphate, 0.75 parts of polyvinylpyrrolidone, 1.5 parts of sheep oil, 0.75 parts of cinnamon oil, 1.5 parts of polyanionic cellulose, sodium silicate 0.2 parts, polyoxyethylene sorbitan laurate 1.5 parts, acrylic milk mortar 0.75 parts, water 7 parts.

[0043] The preparation method of above-mentioned composite ceramic material is:

[0044] Step 1: Grind porcelain stone, pyrophyllite and quartz sand into powder and mix them;

[0045] The second step: mix polyethylene oxide, polyanionic cellulose, sodium alginate and water, and stir for 15 minutes to form a paste;

[0046] Step 3: Mix all the components, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com