Hot gas pipeline gas flow distributor type temperature adjusting device

A temperature adjustment device and airflow distribution technology, which is applied in lighting and heating equipment, refrigeration safety arrangements, refrigeration components, etc., can solve the problems of airflow temperature instability, influence, energy waste, etc., and achieve the effect of reducing energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

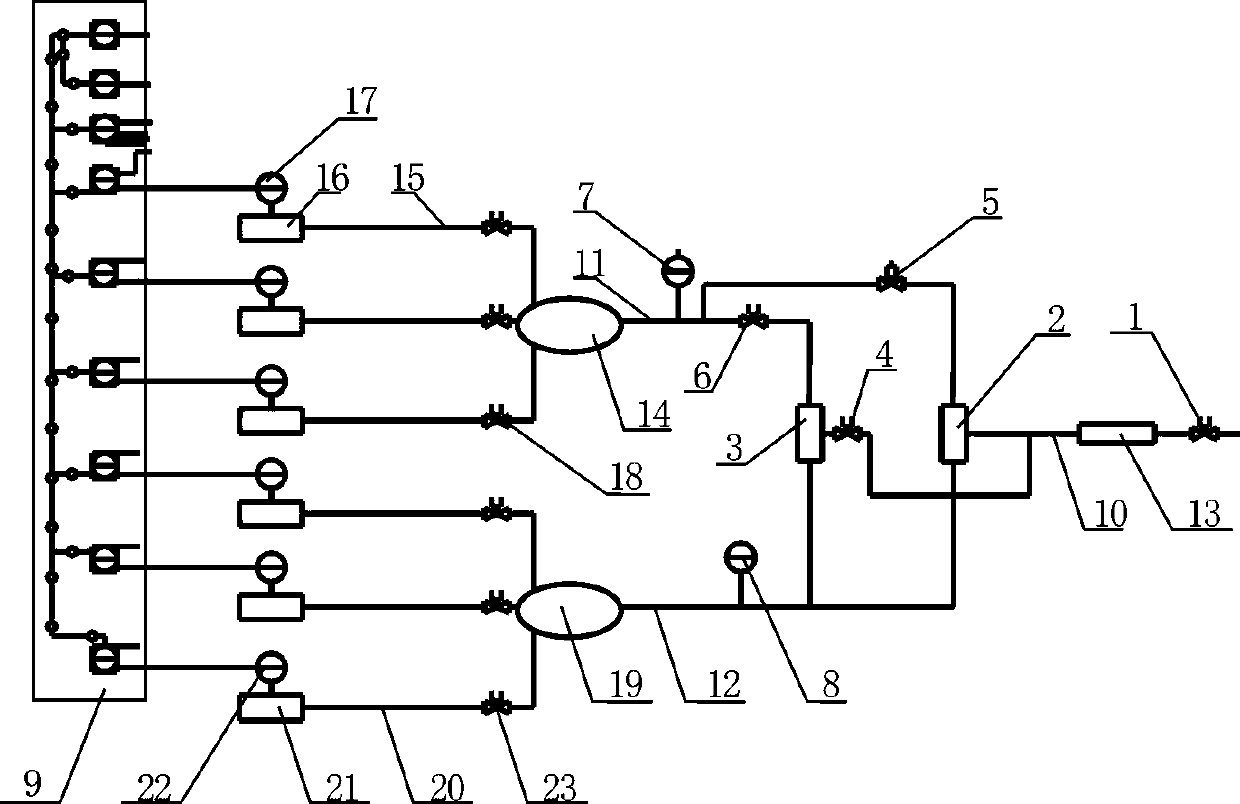

[0010] Such as figure 1 As shown, the hot gas pipeline air distributor type temperature adjustment device includes a flow control solenoid valve 1, a vortex tube A2, a vortex tube B3, an intake control solenoid valve 4, a cooling coefficient adjusting solenoid valve A5, a cooling coefficient adjusting solenoid valve B6, The temperature sensor A7, the temperature sensor B8 and the controller 9, the vortex tube A2 and the vortex tube B3 are installed in parallel, in the vortex tube A2 and the vortex tube B3, the compressed air input end is connected to the same intake pipe 10, and the hot air flow is output The end is connected to the same hot air pipe 11, and the cold air output end is connected to the same cold air pipe 12. The flow control solenoid valve 1 is provided on the intake pipe 10, and the intake control solenoid valve 4 is provided on the vortex tube. The compressed air input end in B3, the coefficient of refrigeration adjustment solenoid valve A5 and the coefficient...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap