Alloy processing method

A processing method and alloy technology, which are applied in the field of sputtering targets, can solve the problem that the performance of the target blank needs to be improved, and achieve the effects of uniform heating and uniform structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

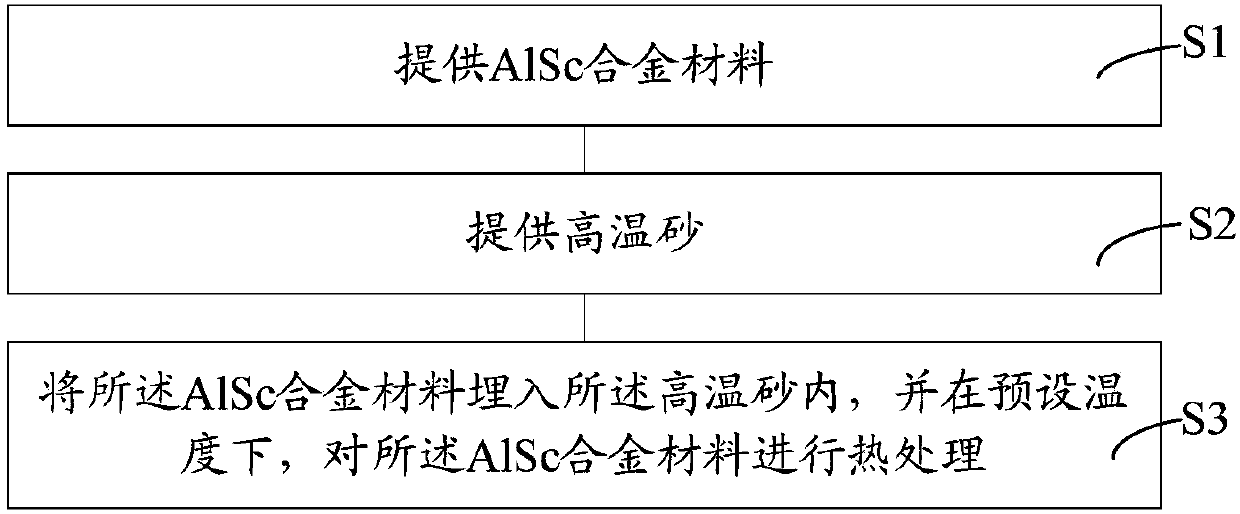

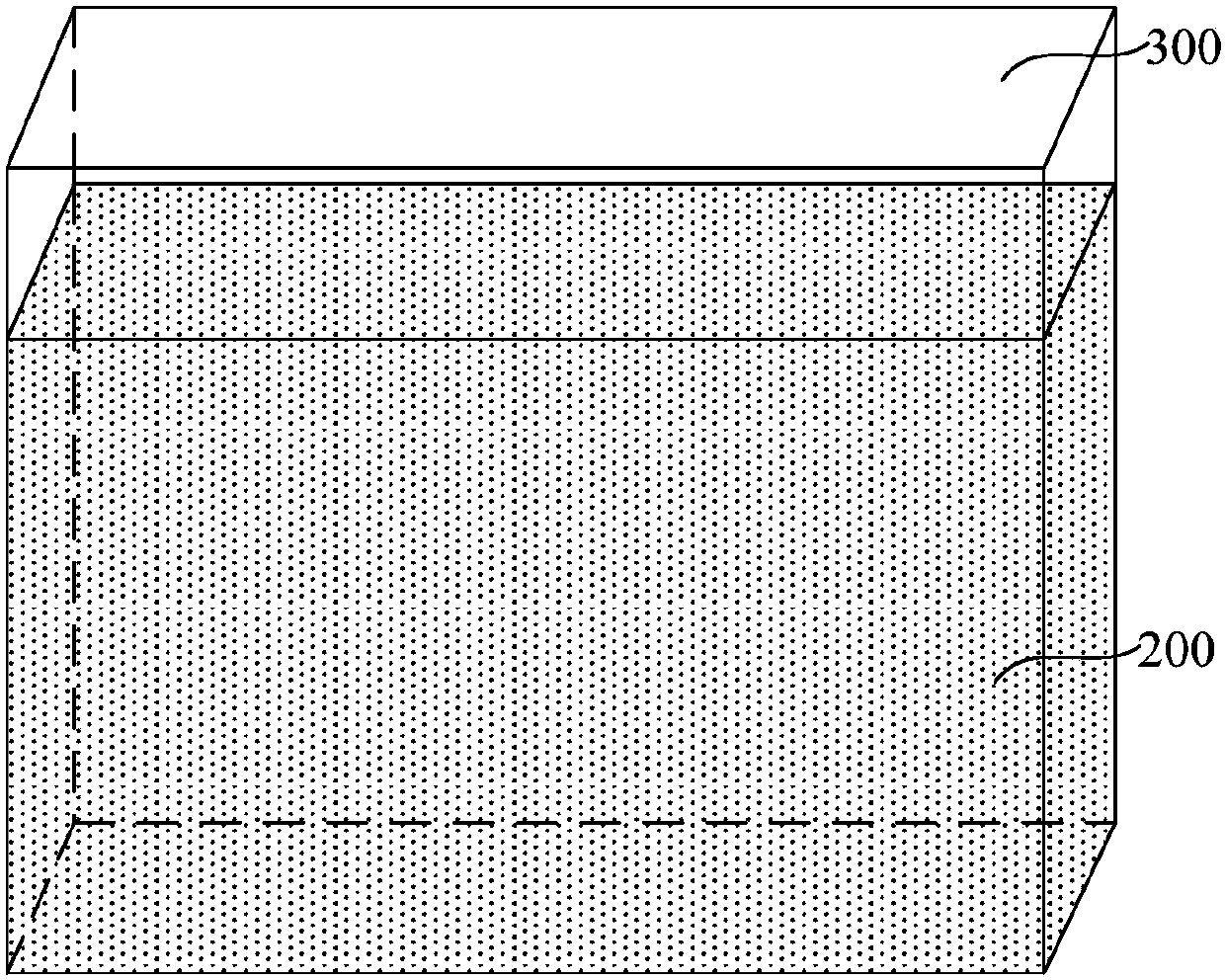

[0022] AlSc alloy has been gradually used in the manufacture of target blanks due to its superior properties such as good corrosion resistance, mechanical strength, toughness, heat resistance, plasticity and weldability. In the manufacturing process of target blanks, the current heat treatment method for AlSc alloy is mainly: placing the AlSc alloy in a heating furnace, and heat-treating the AlSc alloy through convection or radiation heat transfer.

[0023] However, in the process of placing the AlSc alloy in a heating furnace for heat treatment, it is difficult to ensure that the temperature in the heating furnace is stable, and it is difficult to ensure that the AlSc alloy is heated uniformly, resulting in the structure of the AlSc alloy in the transverse and longitudinal directions. The structure is inconsistent due to uneven heating, which makes it difficult for the formed target blank to meet the requirements of target sputtering.

[0024] In order to solve the above problems,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap