Method for operating an electrically actuable feed pump in a hydraulic circuit

A technology of hydraulic circuits and delivery pumps, which is applied in the directions of transportation and packaging, registration/indicating vehicle operation, transmission control, etc., and can solve problems such as high cost, error-prone, and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

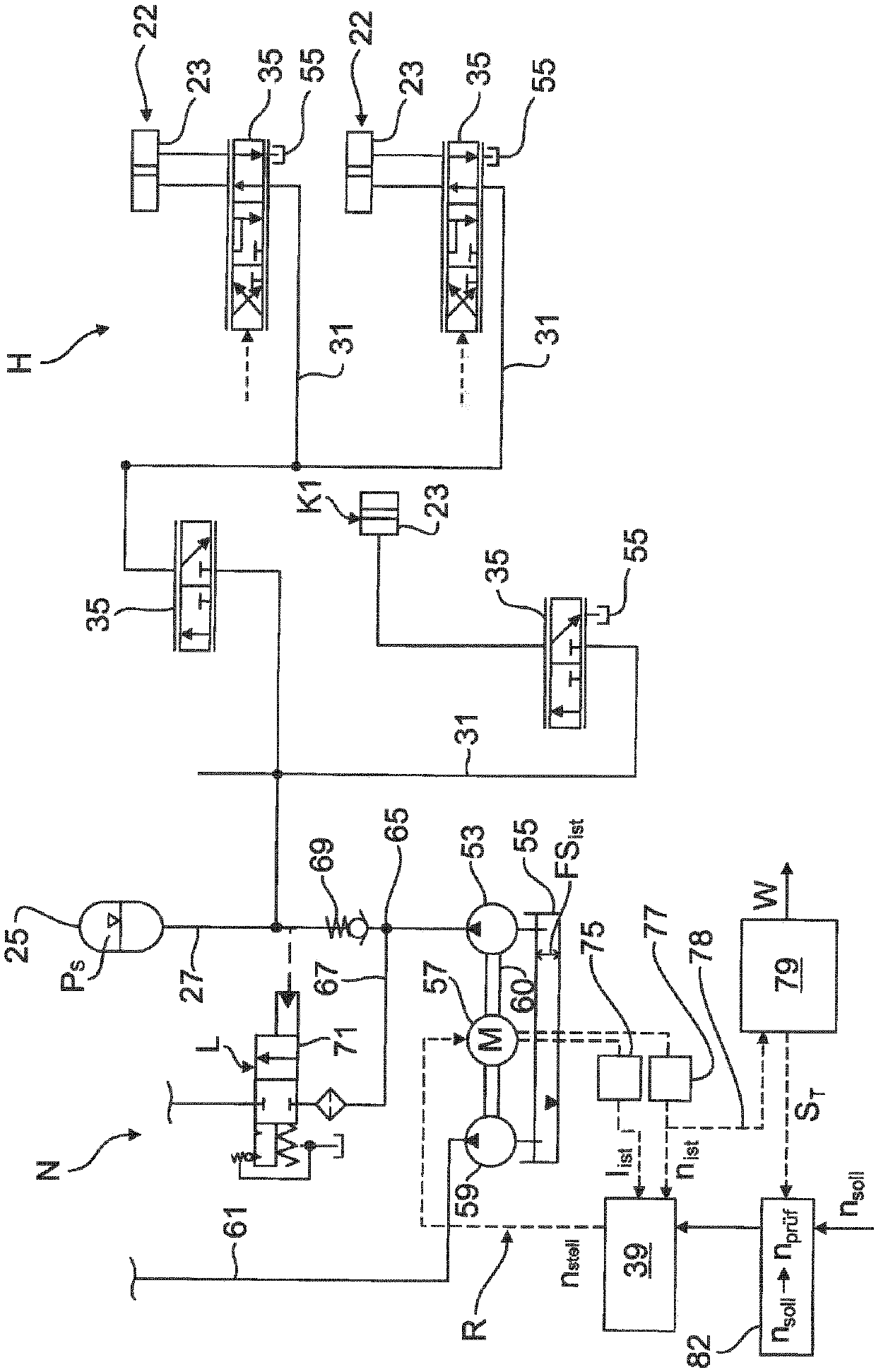

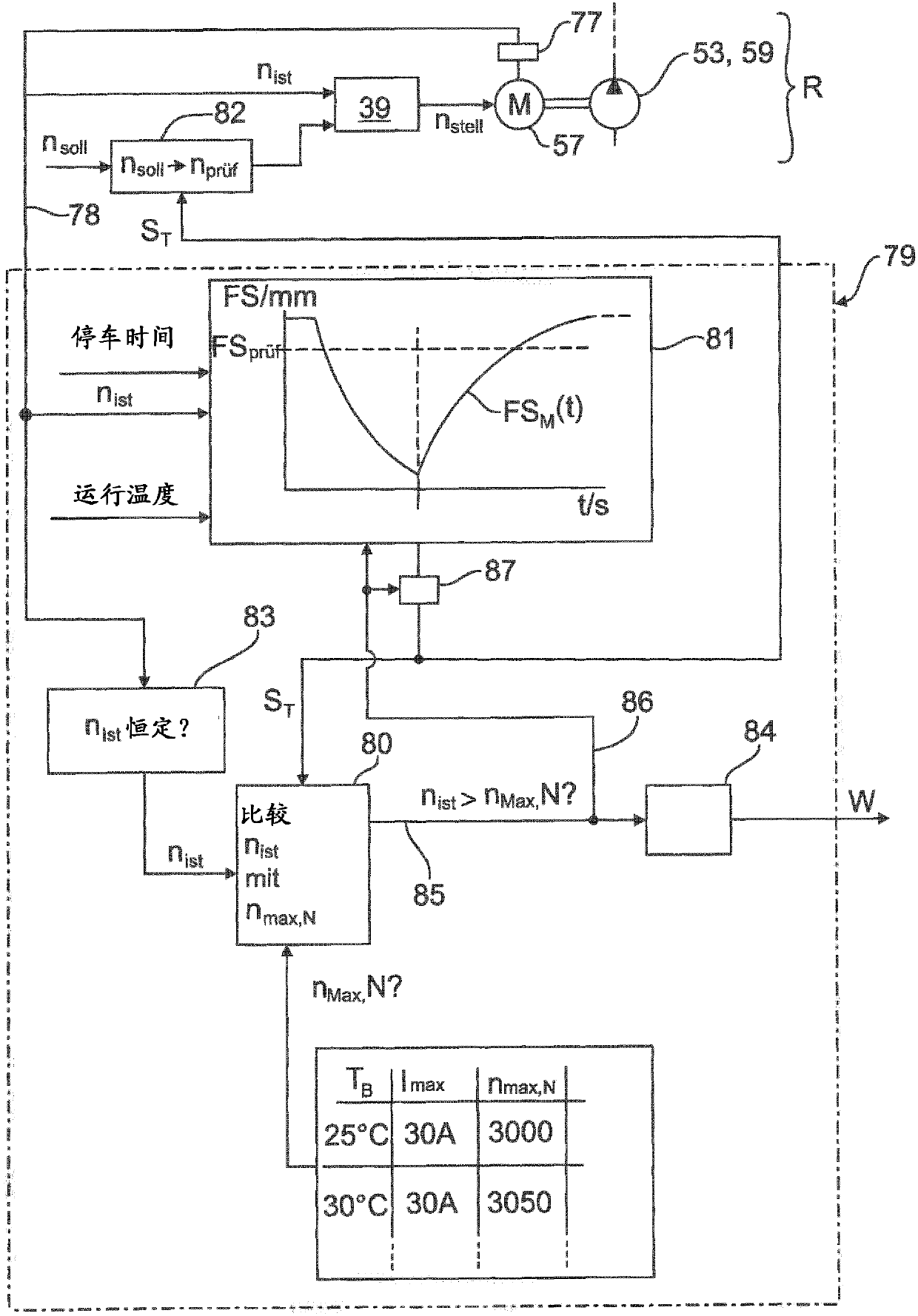

[0021] exist figure 1 The hydraulic system of a dual-clutch transmission of a motor vehicle is shown in an extremely simplified block diagram. By way of example, the hydraulic cylinder 23 of the clutch K1 and the hydraulic cylinder 23 of the actuator 22 are actuated by means of a hydraulic system. The actuator 22 is, for example, a double synchro clutch by means of which the gear changes in the dual clutch transmission take place. hydraulic system in figure 1 There is a high-voltage circuit H and a low-pressure circuit N in it. In the high-pressure circuit H, the disengagement clutch (in figure 1 Only the clutch K1) and the hydraulic cylinder 23 of the actuator 22 connected therein are shown in the figure, and the accumulator pressure p can be applied via the accumulator 25 s . For this purpose, the main line 27 , which is connected to the pressure accumulator 25 , leads to the hydraulic cylinder 23 via a sub-line 31 , not described further. A control valve 35 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com