Method for preparing tungsten silicide coating layer on surface of tungsten or tungsten alloy

A technology of tungsten alloy and tungsten silicide, which is applied in the field of high-temperature protective coatings, can solve the problems of further improvement and large difference in thermal expansion coefficient, achieve good high-temperature oxidation resistance, reduce thermal expansion coefficient mismatch, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A tungsten silicide coating on a tungsten metal surface, the preparation of which comprises the steps of:

[0035] 1) Sandblasting the surface of the W substrate with a sandblasting pressure of 0.4 MPa, sonicating twice in absolute ethanol solution for 5 minutes each time, drying at 100°C for 2 hours, and set aside;

[0036] 2) Use silicon powder with a median particle size of about 30 μm and a purity greater than 98wt.% as the raw material for spraying, dry at 100°C for 3 hours, and set aside;

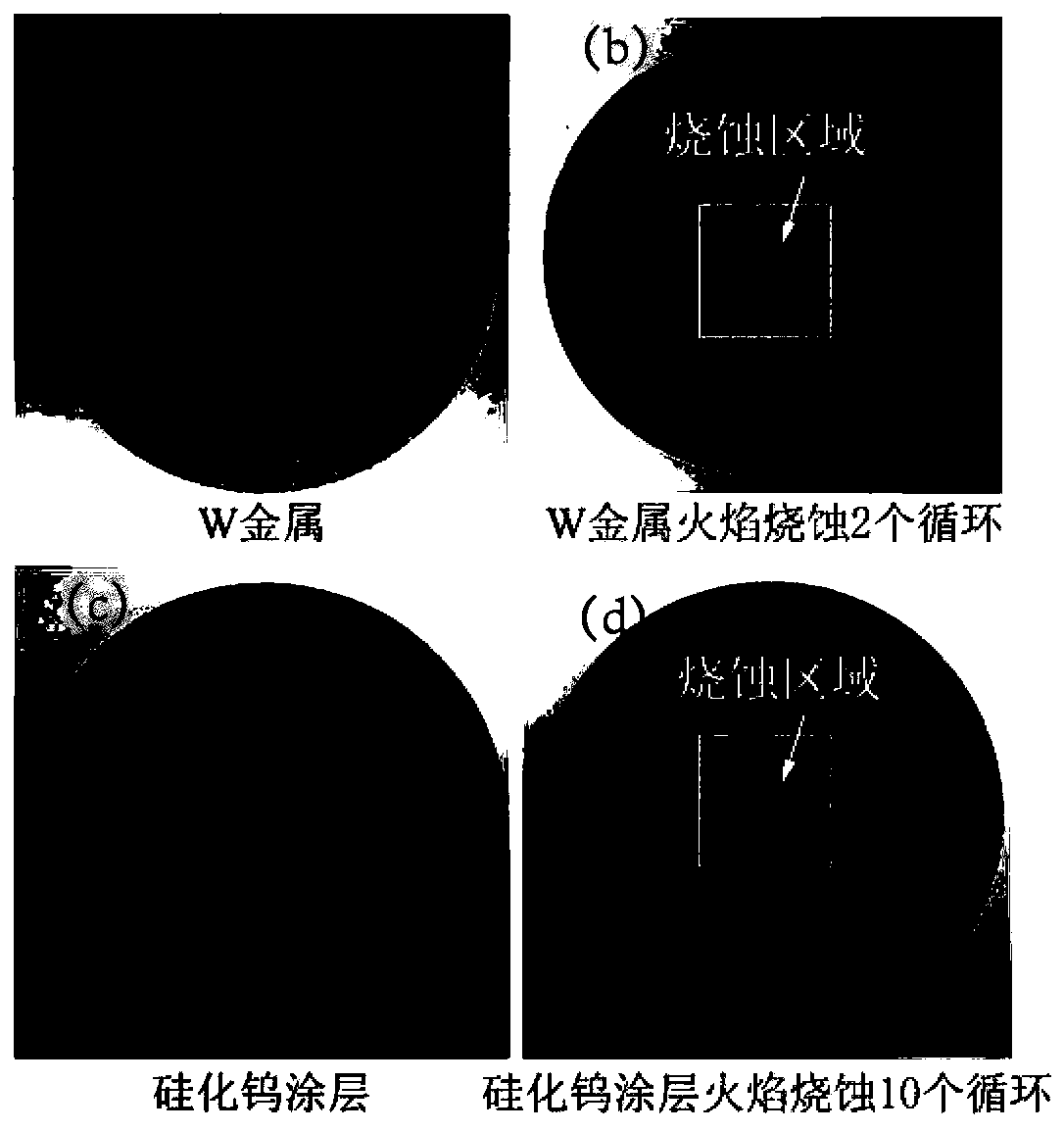

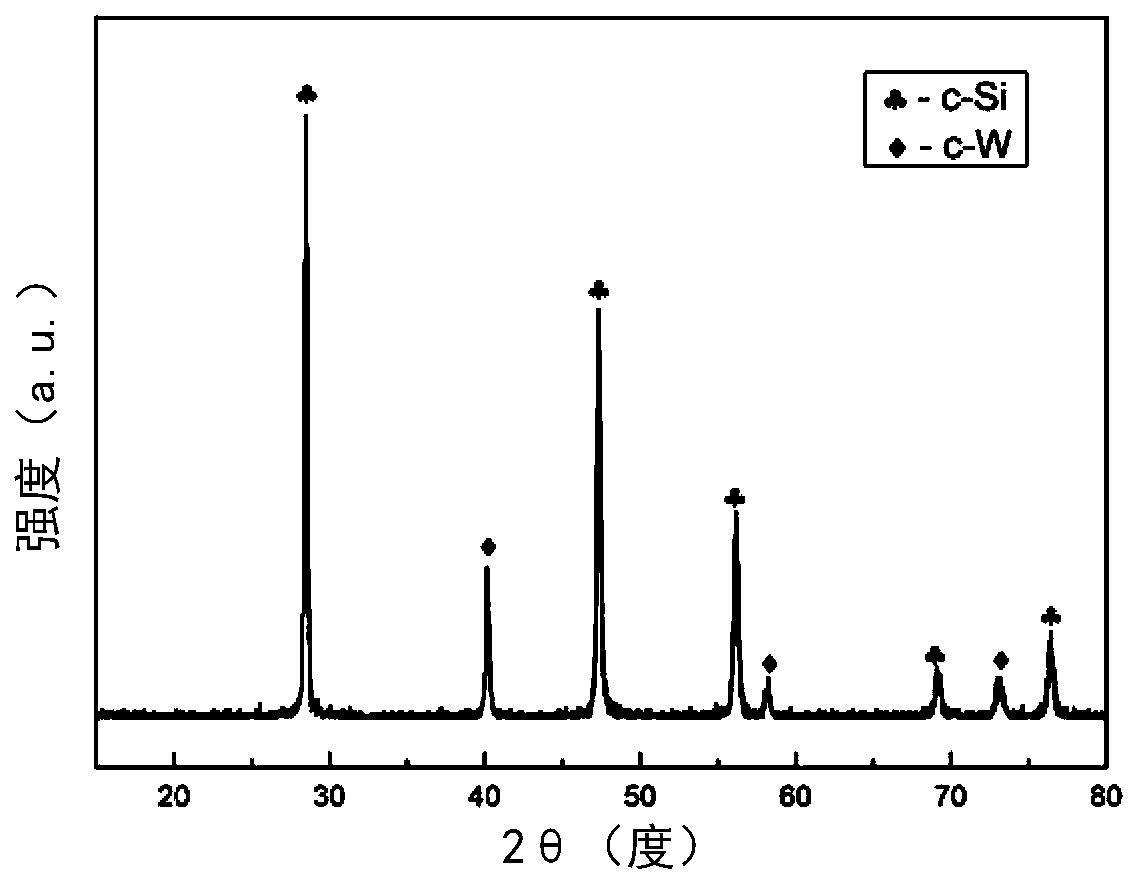

[0037] 3) Using a plasma spraying system (A-2000, Sulzer Metco AG, Switzerland), select the process parameters in Table 1, spray silicon powder onto the surface of the W substrate to form a silicon coating, the thickness of the silicon coating is about 110 μm, figure 1 The XRD results show that the silicon coating is a cubic phase;

[0038] Table 1 is the process parameters of plasma spraying Si coating:

[0039]

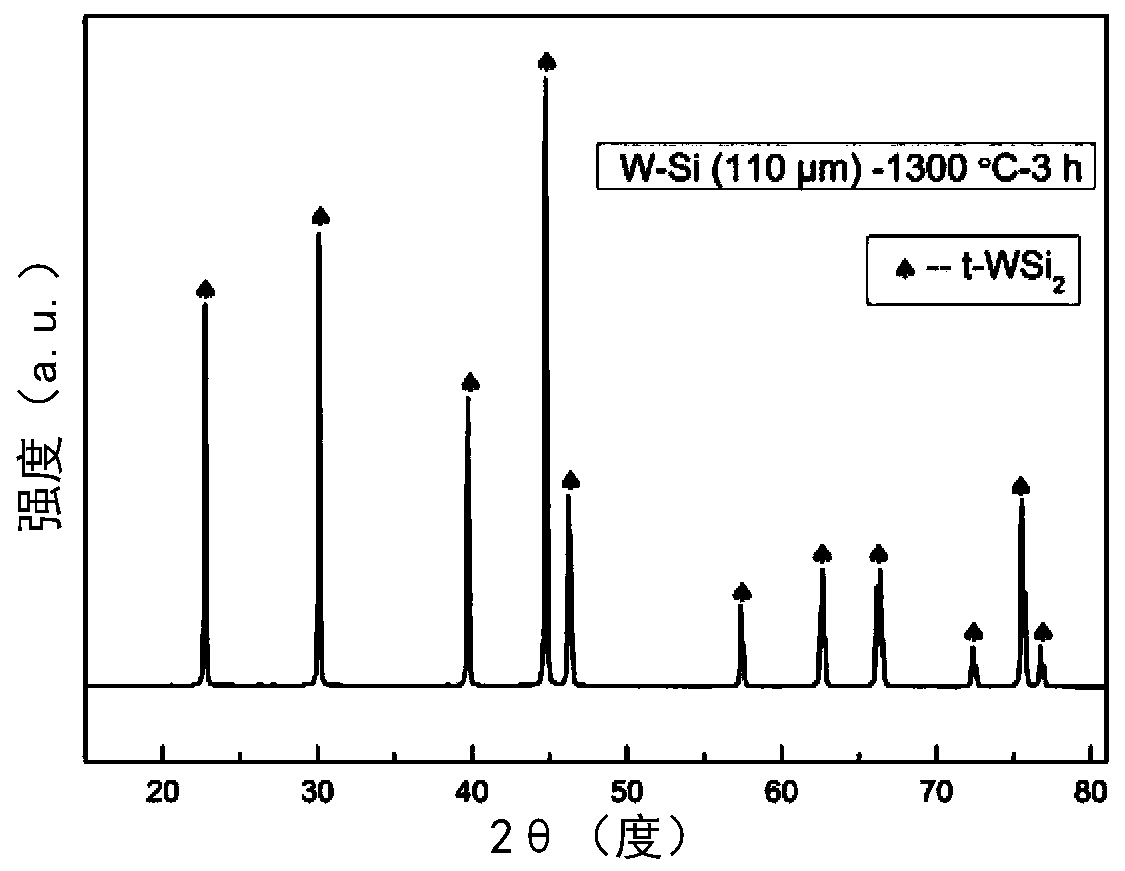

[0040] 4) Using argon-protected vacuum-atmosphere sinterin...

Embodiment 2

[0055] A tungsten silicide coating on a tungsten metal surface, the preparation of which comprises the steps of:

[0056] 1) Sandblasting the surface of the W substrate with a sandblasting pressure of 0.4 MPa, sonicating twice in absolute ethanol solution for 5 minutes each time, drying at 100°C for 2 hours, and set aside;

[0057] 2) Use silicon powder with a median particle size of about 30 μm and a purity greater than 98wt.% as the raw material for spraying, dry at 100°C for 3 hours, and set aside;

[0058] 3) Using plasma spraying technology and selecting the process parameters in Table 3, spray silicon powder onto the surface of the W substrate to form a silicon coating. The thickness of the silicon coating is about 110 μm. figure 1 The XRD results show that the silicon coating is a cubic phase;

[0059] 4) A vacuum-atmosphere sintering furnace protected by argon is used, and a diffusion reaction occurs between the silicon coating and the W substrate to form a tungsten s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com