A kind of Bacillus coagulans and fermentation method thereof, preparation method of Bacillus coagulans preparation and pig feed

A Bacillus coagulans, fermentation method technology, applied in animal feed, animal feed, microbial-based methods, etc., can solve problems such as high temperature resistance, limited ability to resist acid and bile salts, performance impact, and reduce the application value of Bacillus coagulans, etc. Achieve the effect of improving application value and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

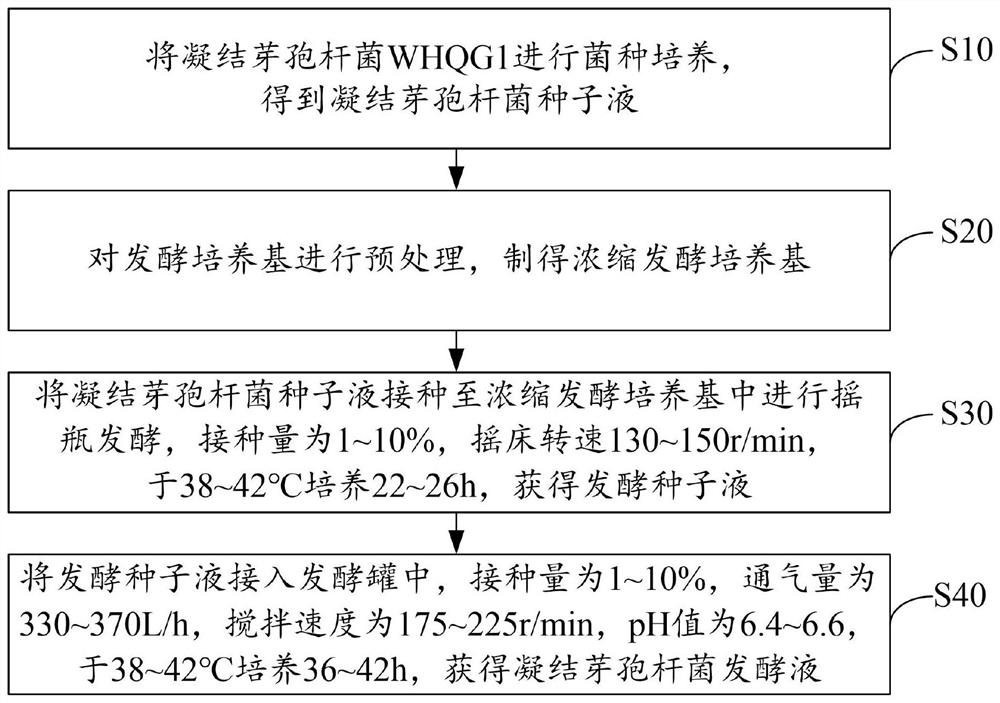

Method used

Image

Examples

preparation example Construction

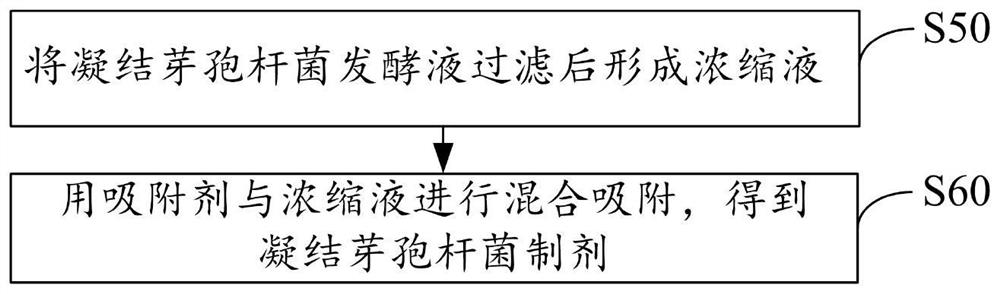

[0056] The present invention also proposes a preparation method of Bacillus coagulans preparation, image 3 It is an example of the preparation method of the Bacillus coagulans preparation. see image 3 , the preparation method of described Bacillus coagulans preparation comprises the following steps:

[0057] Step S50, filtering the Bacillus coagulans fermentation broth to form a concentrated solution;

[0058] The Bacillus coagulans fermentation liquid prepared by the fermentation method of Bacillus coagulans provided by the above steps S10 to S40 is taken out from the fermenter, filtered and concentrated until the supernatant basically no longer flows out to form the concentrated liquid. In the embodiment of the present invention, the specific implementation of the filtration can be carried out by using an organic ceramic membrane filtration device, and the Bacillus coagulans fermentation liquid is poured into the hopper of the organic ceramic membrane filtration device, ...

Embodiment 1

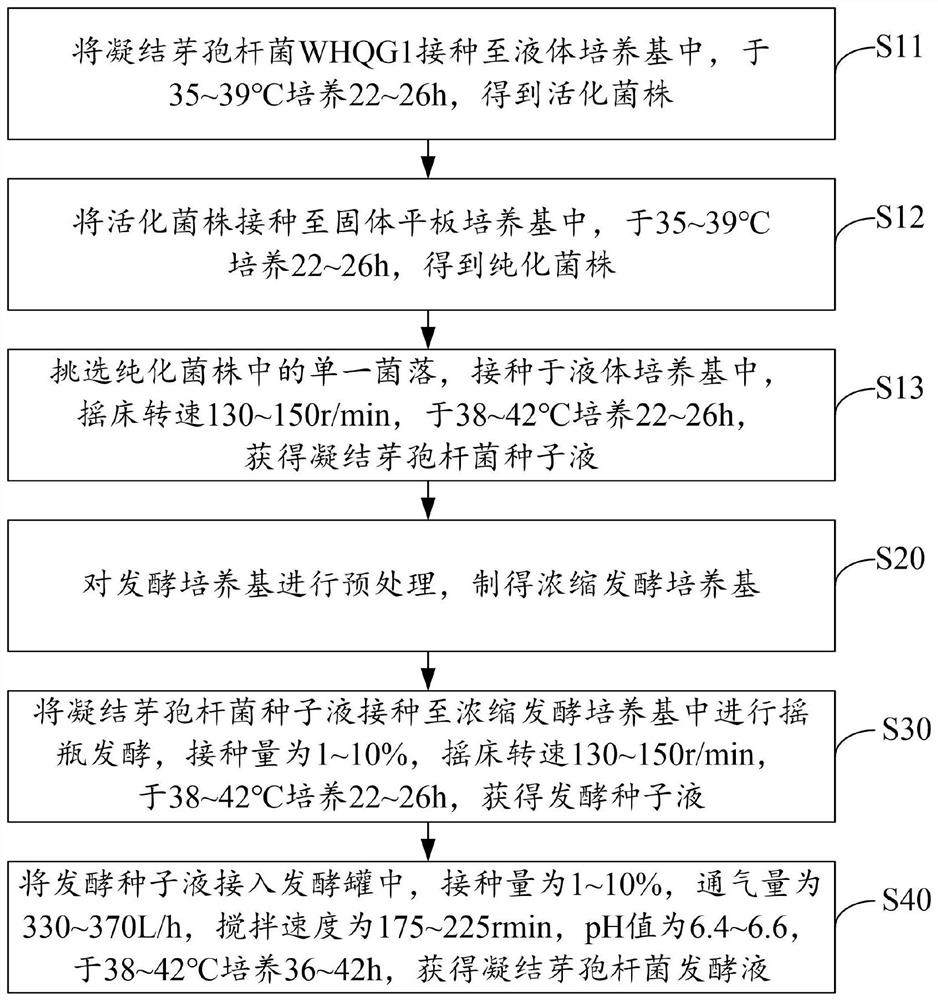

[0064] Example 1 bacterial culture

[0065] (1) Strain activation: Bacillus coagulans WHQG1 was placed in a liquid medium and cultured at 37°C for 24 hours to obtain an activated strain. The preparation method of the medium was as follows: tryptone 10g / L, beef Extract 3g / L of powder and 5g / L of sodium chloride, adjust the pH value to 6.4-6.6, sterilize at 121°C for 20min and then cool to room temperature.

[0066] (2) Purification of strains: connect the activated strains in step (1) to a solid plate medium, and cultivate at 37° C. for 24 hours to obtain purified strains. The preparation method of the medium is as follows: tryptone 10g / L, Beef extract powder 3g / L, sodium chloride 5g / L and agar 15g / L, adjust the pH value to 6.4-6.6, sterilize at 121 ℃ for 20min and cool to room temperature.

[0067] (3) Preparation of seed liquid: select a single colony in the purified strain in step (2), inoculate it into a liquid medium (same as step (1)), shake the rotating speed at 140 r / m...

Embodiment 2

[0068] Example 2 Fermentation culture

[0069] (1) fermentation medium pretreatment: the fermentation medium and water are mixed according to the mass ratio of 1:3, boiled for 30min, and the concentrated fermentation medium is obtained after filtration, wherein, the preparation method of the fermentation medium is as follows: corn flour 5g / L , wheat bran 10g / L, ammonium chloride 7.5g / L, soybean meal powder 7.5g / L, sodium chloride 5g / L, MnSO 4 ·H 2 O 0.3g / L and K 2 HPO 4 ·3H 2 O 1 g / L; the pH value of the fermentation medium is 6.4-6.6, sterilized at 121° C. for 20 min, and then cooled to room temperature.

[0070](2) shake flask fermentation culture: divide 35mL of the concentrated fermentation medium obtained in step (1) with a 250mL conical flask, inoculate 1% of the Bacillus coagulans seed liquid obtained in Example 1, and set the shaker rotation speed At 140 r / min, the fermented seeds were fermented at 40 °C for 24 h on a shaking table to obtain fermented seed liquor....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com