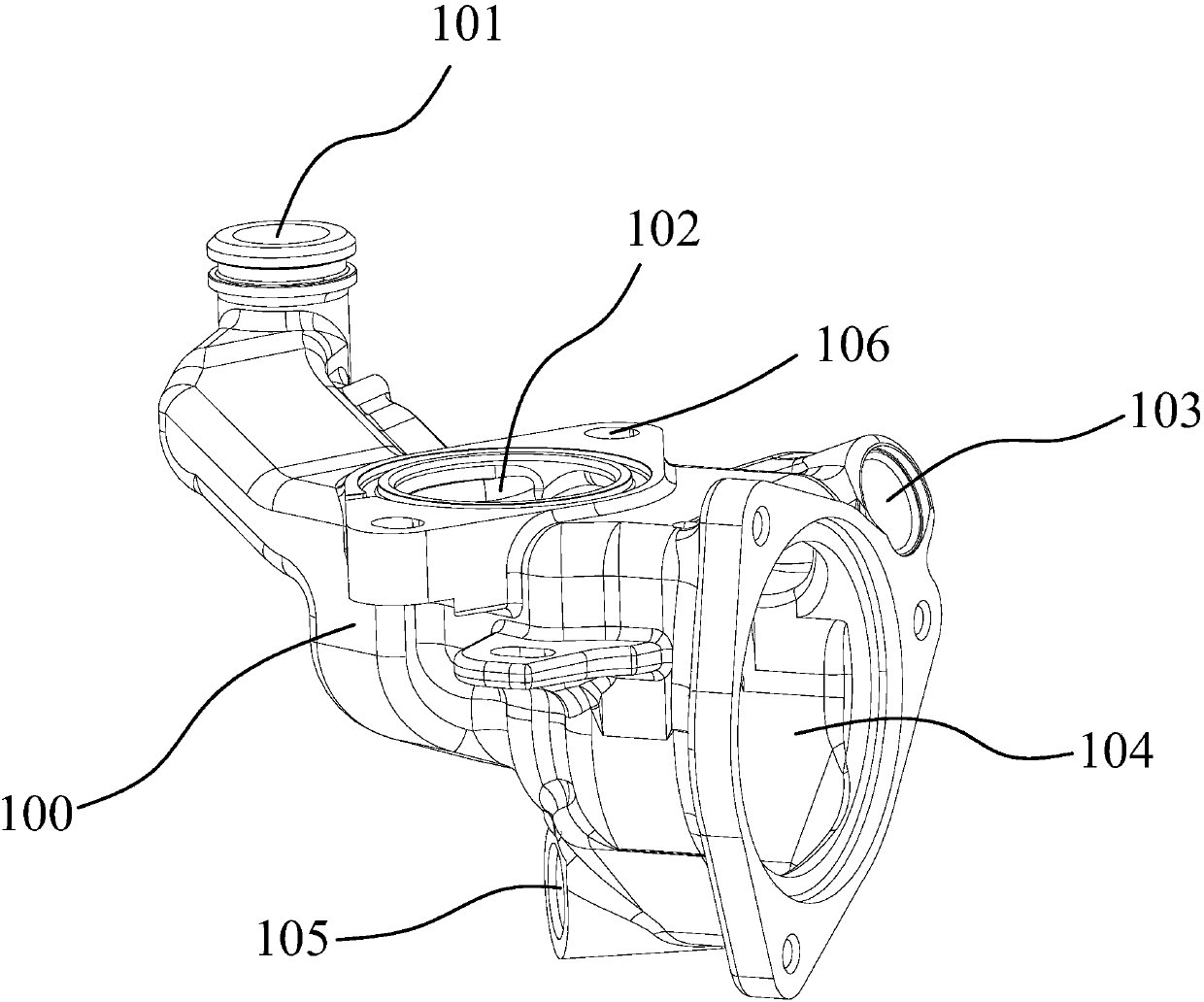

Engine thermostat lower shell air tightness detection tool

An air tightness detection and thermostat technology, which is used in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, and testing of machine/structural components, etc. Problems such as low efficiency and detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

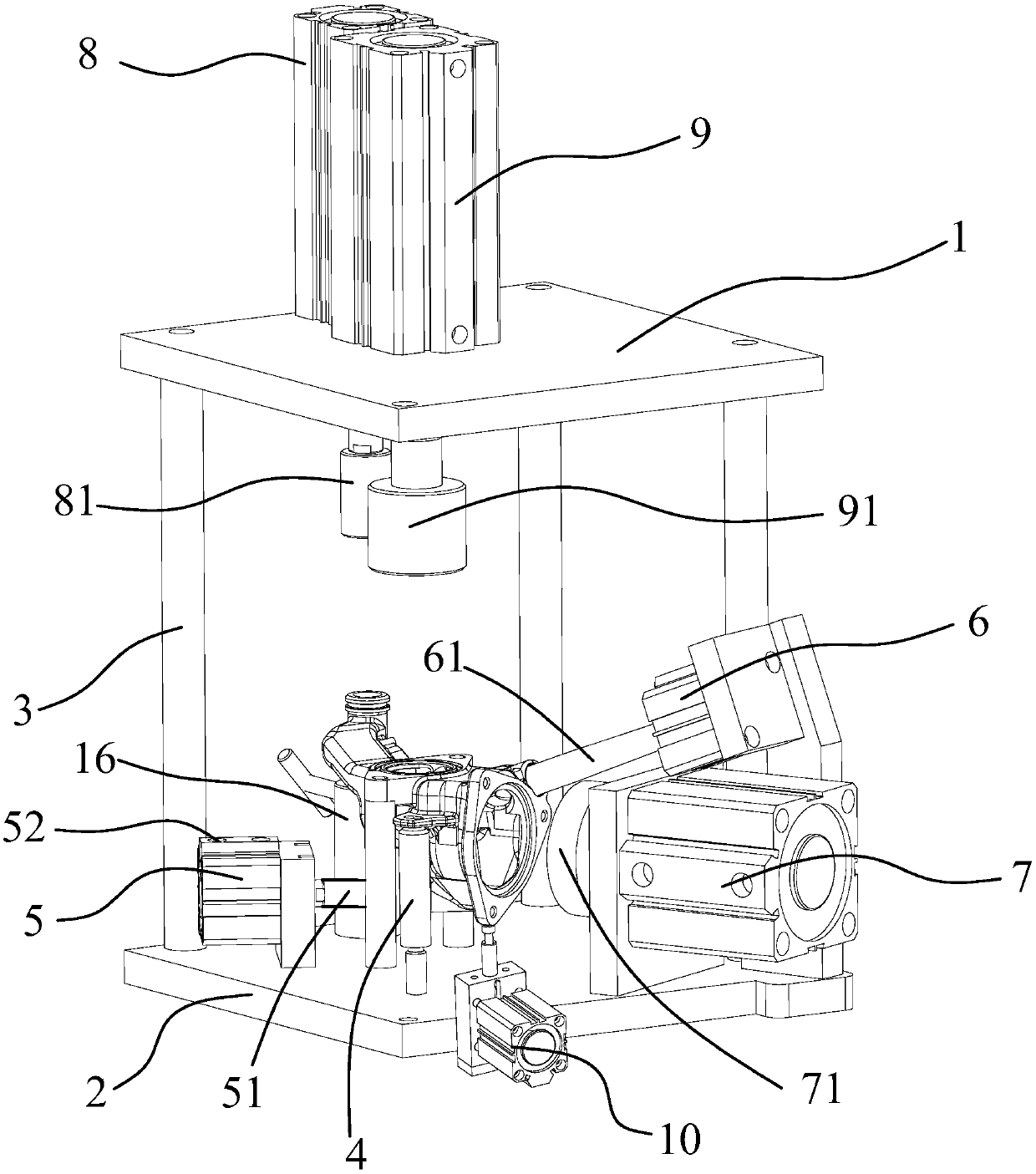

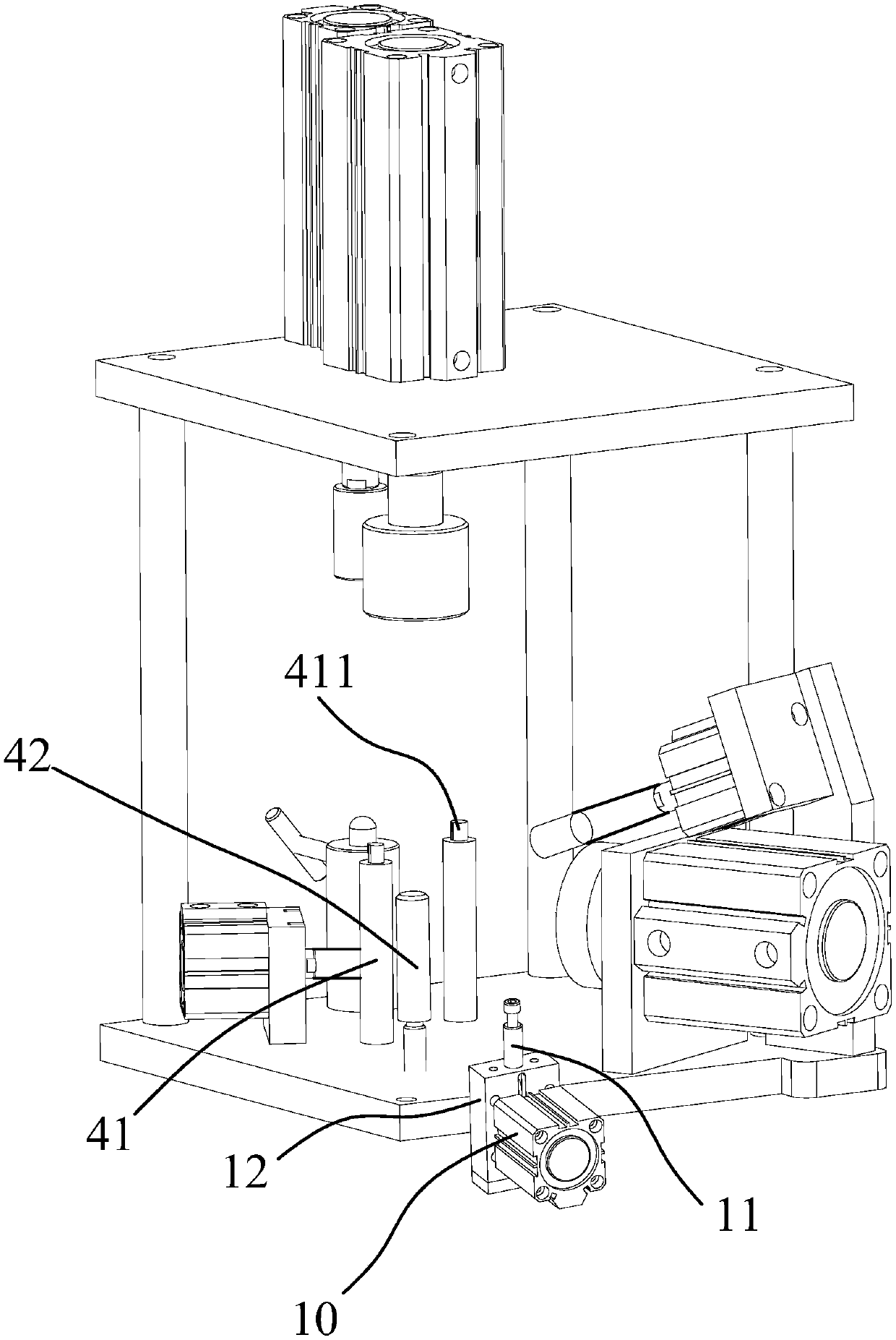

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] like Figure 2-6 As shown, the present invention provides an air tightness detection tool for the lower case of the engine thermostat, which includes an upper base plate 1 and a lower base plate 2, and the four corners of the upper base plate 1 and the lower base plate 2 are fixedly connected by four uprights 3 A simple detection rack with simple structure and large operable space is formed.

[0023] The lower bottom plate 2 is provided with a positioning mechanism 4 for placing the lower casing 100 to be detected. In this embodiment, the positioning mechanism 4 includes a first positioning column 41 and a second positioning column 42. The top of the first positioning column 41 is provided with a Detect the insertion post 411 of the preset through-hole insertion limit on the product 100 .

[0024] The lower bottom plate 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com