An aluminum plate column hole manufacturing device

A technology for making device and column hole, applied in the field of aluminum plate column hole making device, can solve the problems of easy cracking of hole port, low connection reliability, short thread processing length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

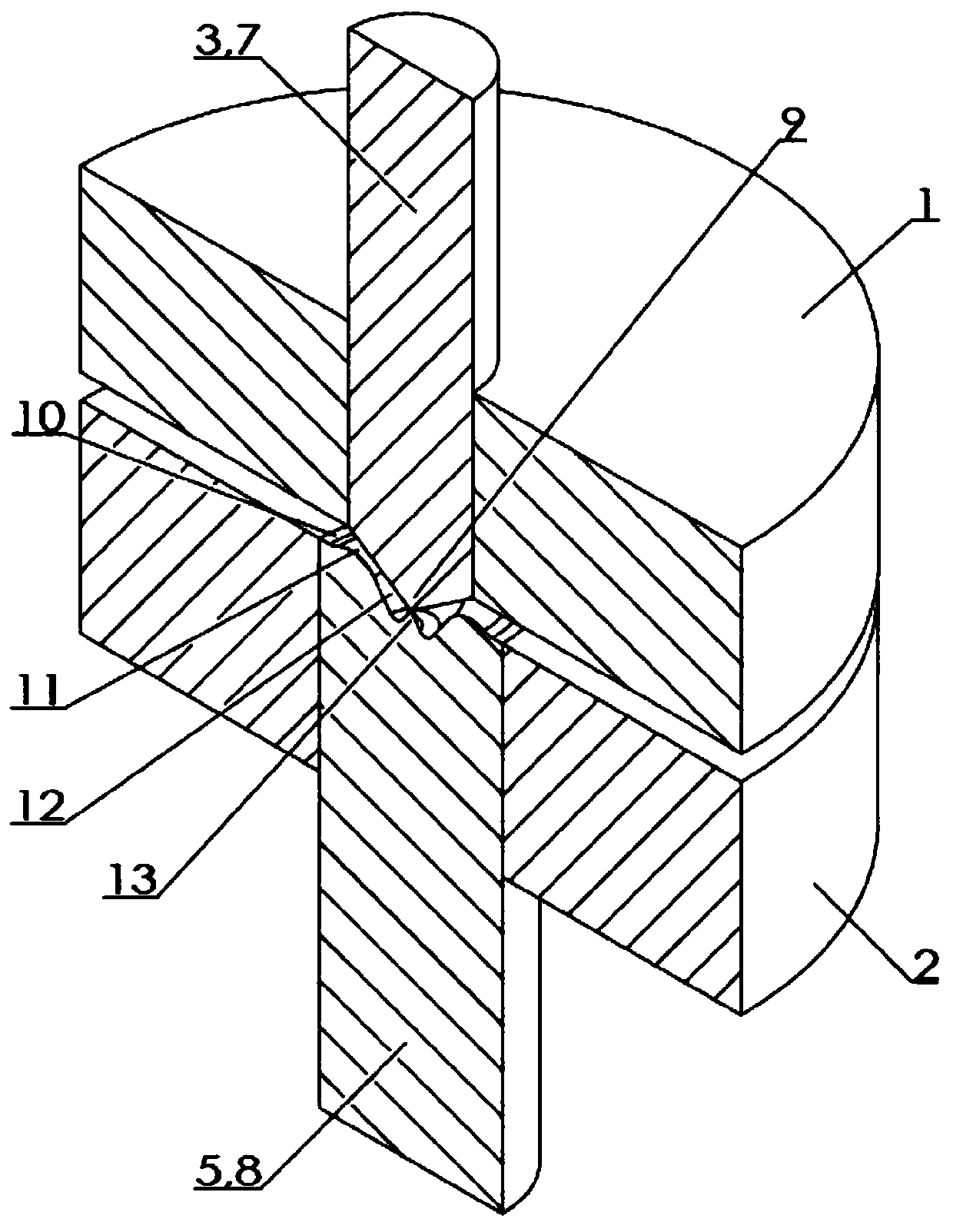

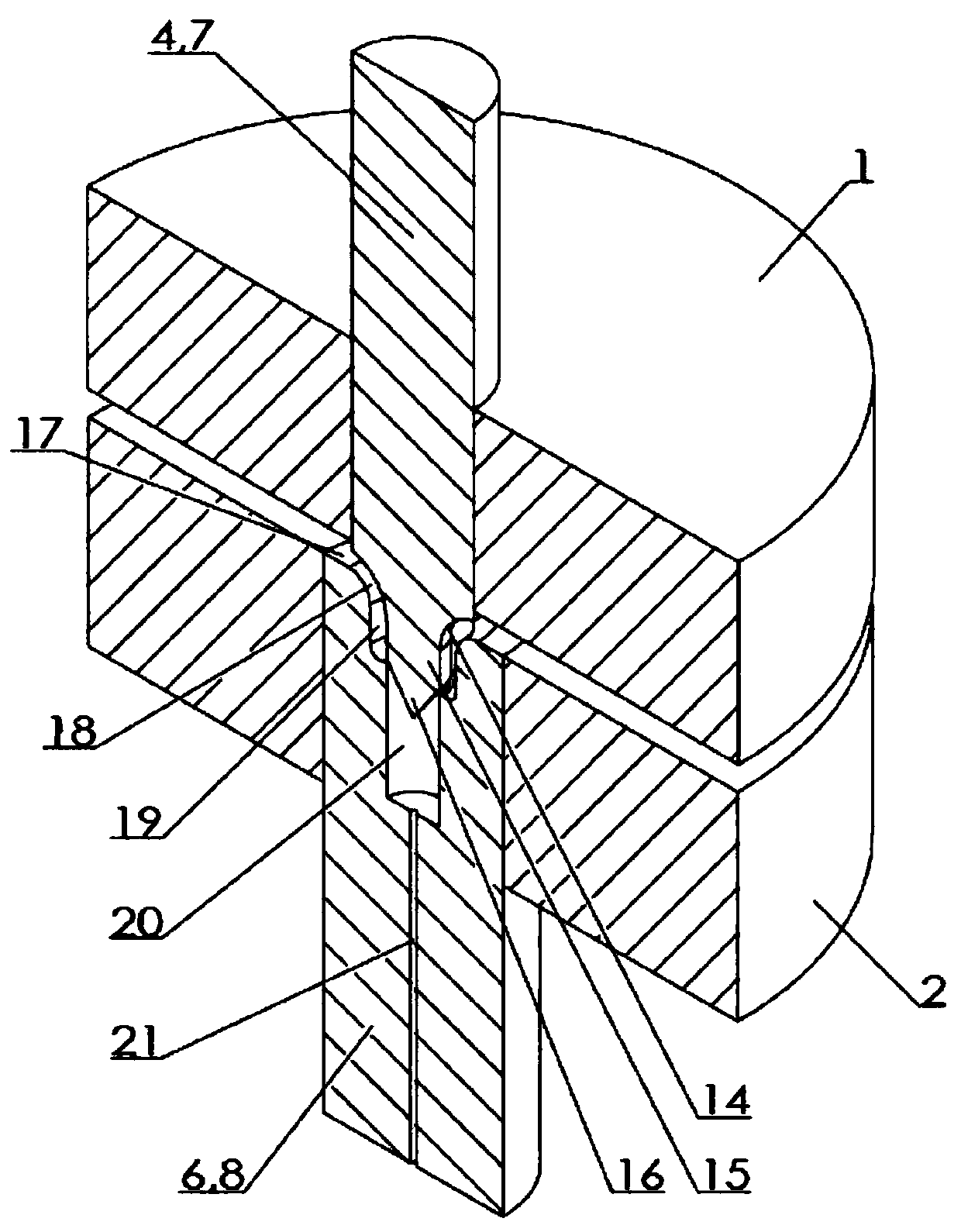

[0010] Examples of the present invention figure 1 , 2 As shown, the aluminum plate column hole manufacturing device is provided with an upper pressing block 1, a lower cushion block 2, a first punching rod 3, a second punching rod 4, a first ejector rod 5 and a second ejector rod 6, the upper pressing block and / or Or the lower pressing block is connected with a pressure driving part, which is used to press the aluminum plate. The upper pressing block and the lower cushion block are respectively provided with relative coaxial upper punching holes 7 and lower top holes 8, and the diameter of the upper punching holes is smaller than that of the lower top. The diameter of the hole is 3 mm to 20 mm. The first punch and the second punch are punches that are equal in diameter to the upper punching hole and can be plugged into the gap. The first ejector and the second ejector are equal in diameter to the lower hole. The ejector rod that can be inserted and pulled out with clearance f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com