Protection device for hot-melt pipe

A protection device and heat-melt tube technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of uneven heating, damage to the heat-melt tube, incomplete shrinkage of the heat-shrinkable tube, etc., and achieve simple structure and convenient heating , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

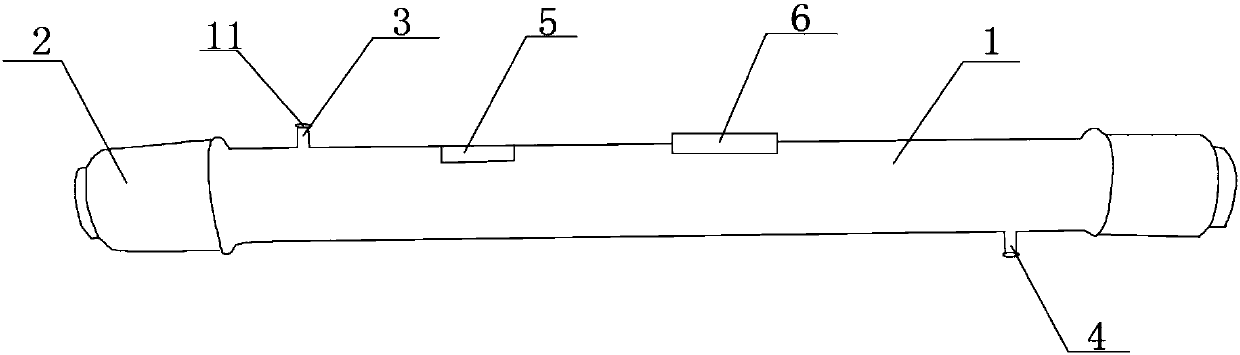

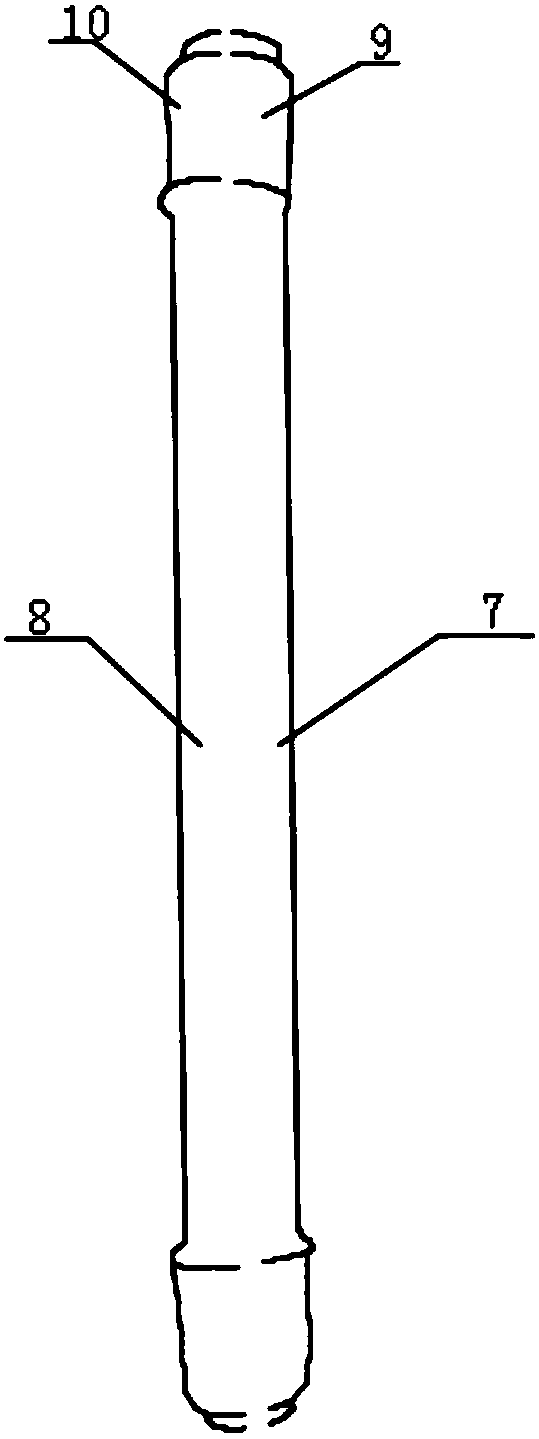

[0023] Such as figure 1 , 2 As shown, a protective device for a hot-melt pipe in the present invention includes a shell 1 and a shell cap 2. The number of the shell caps 2 is two, which are respectively threaded to the two ends of the shell 1. The shell cap 2 belongs to Both ends of the housing are provided with openings, the upper surface of the housing 1 is provided with an air inlet 3, the lower surface of the housing 1 is provided with an air outlet 4, and the housing 1 is provided with a temperature sensor 5 and a temperature display screen 6, the temperature sensor 5 is arranged inside the casing 1, the temperature display screen 6 is arranged outside the casing 1, the output end of the temperature sensor 5 is connected to the output end of the temperature display screen 6, and the casing 1 also includes The upper half shell 7 and the lower half shell 8 are connected by screws between the upper half shell 7 and the lower half shell 8, and the shell cap 2 includes an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com